Turning lens cone assembly based on rolling and pitching platform and assembling and adjusting method thereof

A technology of turning mirrors and components, applied in the directions of installation, optical components, optics, etc., can solve the problems of increased load of the rolling platform, no installation and adjustment plan expression, etc., to meet the requirements of position accuracy, meet the requirements of imaging quality, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

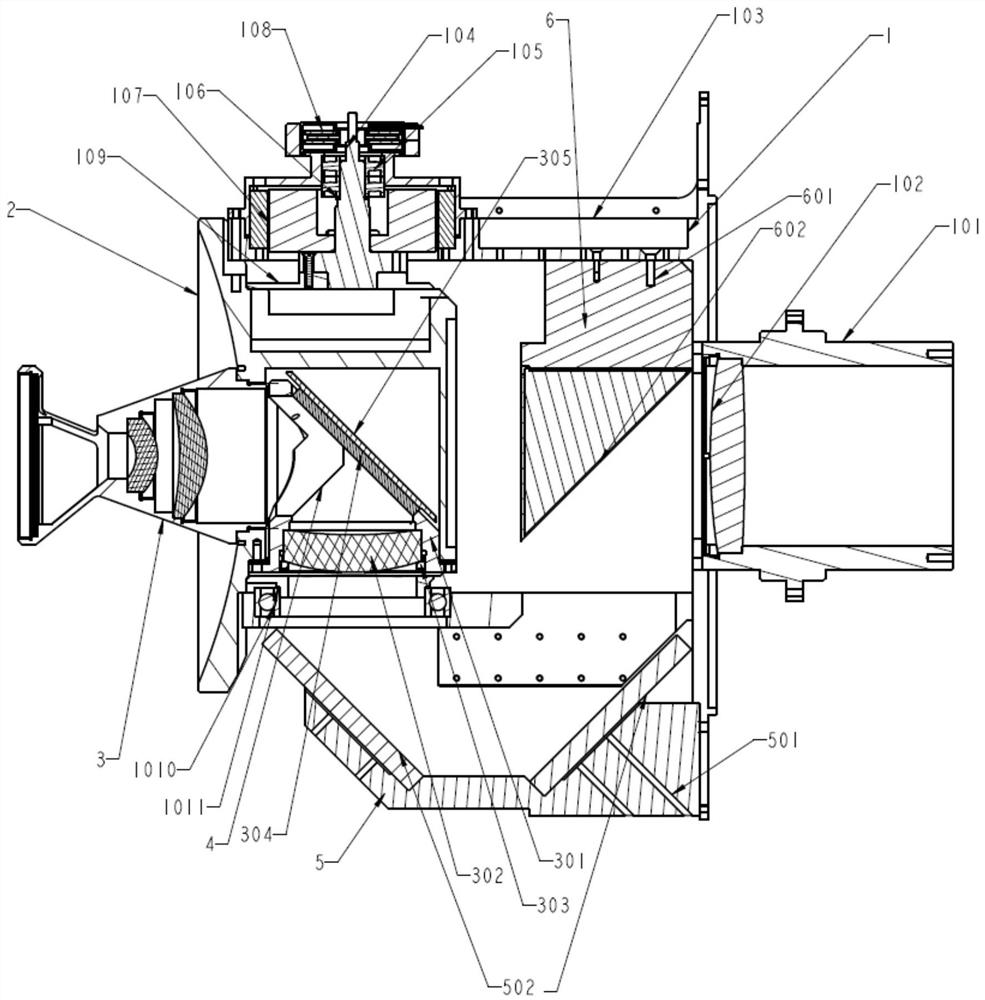

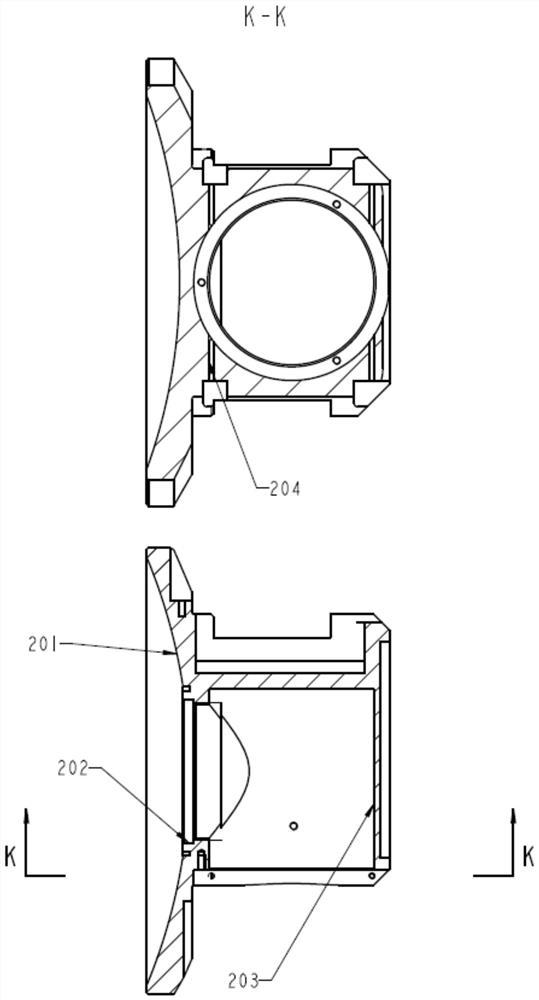

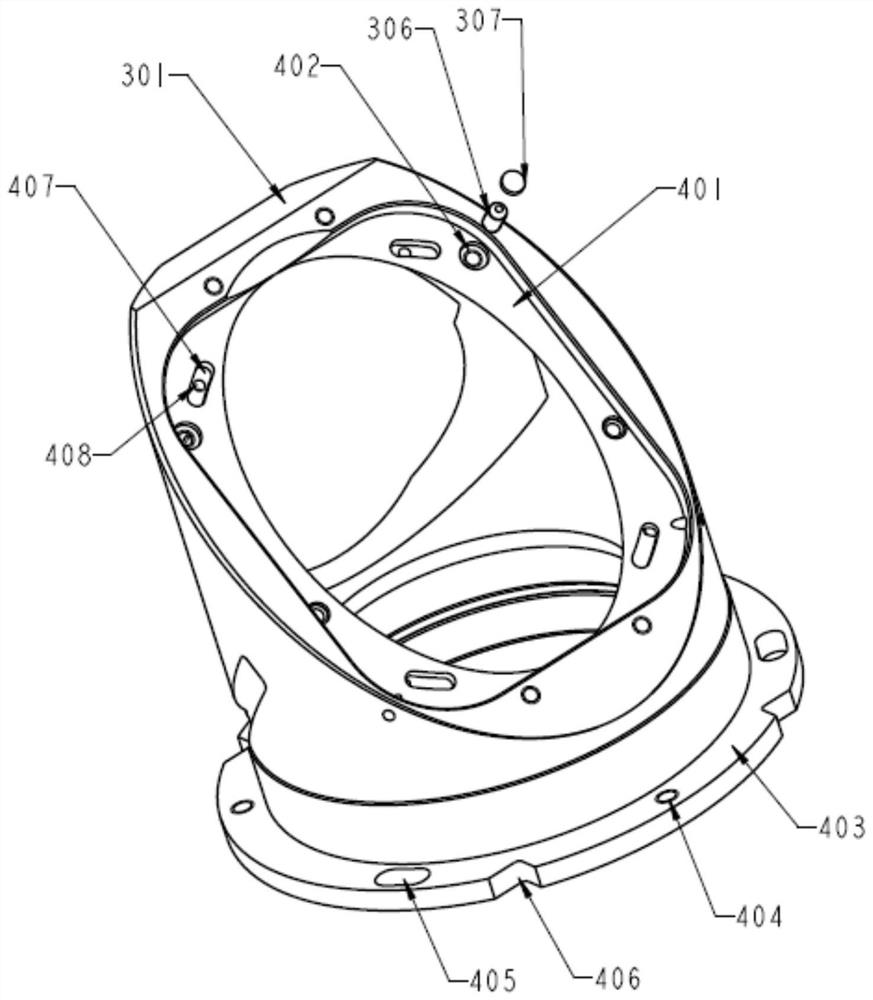

[0037] Such as Figure 1-4 As shown, the present invention relates to a turning lens barrel assembly based on a rolling platform, including: a rolling frame platform part 1, an inner frame 2, a secondary lens barrel assembly 3, a mirror seat assembly 4, and a mirror seat assembly 2 3. Mirror seat three components 6.

[0038] The rolling frame platform component 1 includes a rolling shaft 101, a rolling shaft inner lens 102, a rolling frame 103, a pitching shaft 104, a pitching frame bearing one 105, a bearing gasket one 106, a pitching frame motor 107, and a pitching frame code disc 108, casing 109, pitch frame bearing 2 1010, bearing gasket 2 1011;

[0039] The rolling frame 102 is a structure with a central hole and two vertical ears, and each of the vertical ears has a hole coaxial with each other;

[0040] The roll shaft 101 and the center hole of the roll frame 102 are matched with high precision through the shaft hole, and are fastened and connected with screws. The ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com