Unmanned aerial vehicle group automatic inspection system and method for dam defect detection

A defect detection and automatic inspection technology, which is applied in control/adjustment systems, electric vehicles, non-electric variable control, etc., can solve the problems of high labor costs, long distance from the dam surface, and low efficiency, so as to improve the degree of automation and reduce the Labor cost, easy to monitor the effect of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

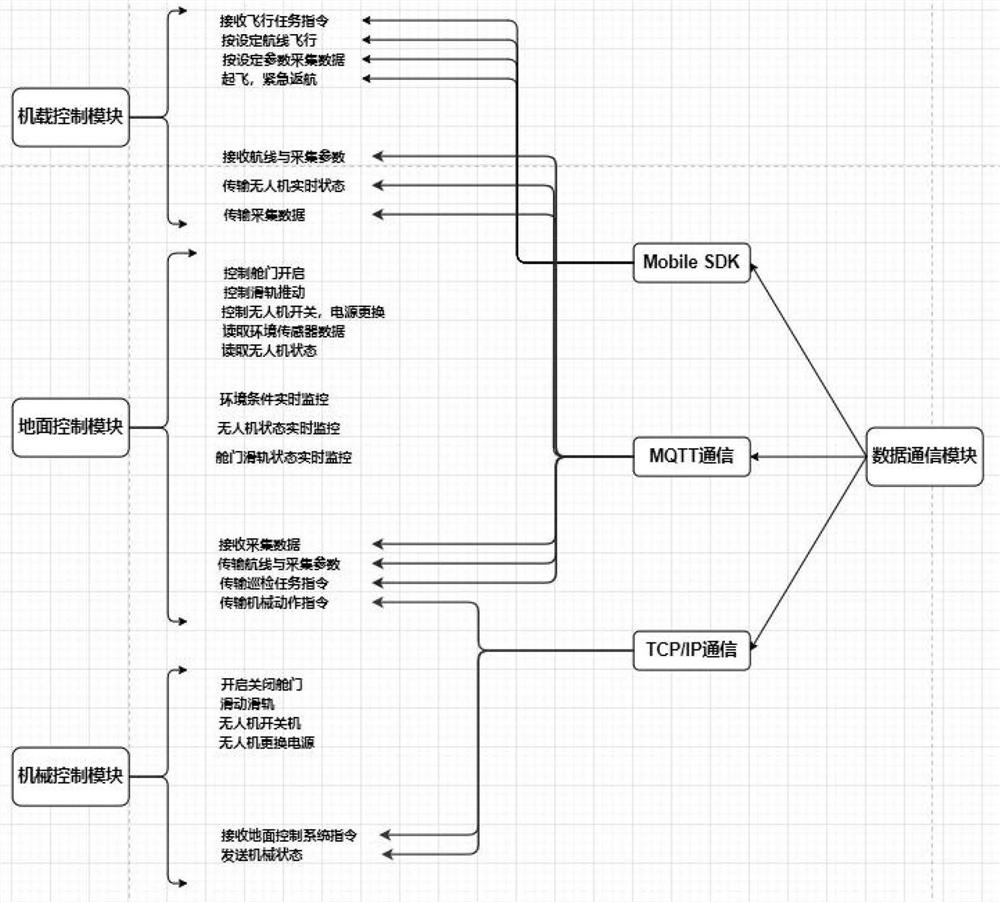

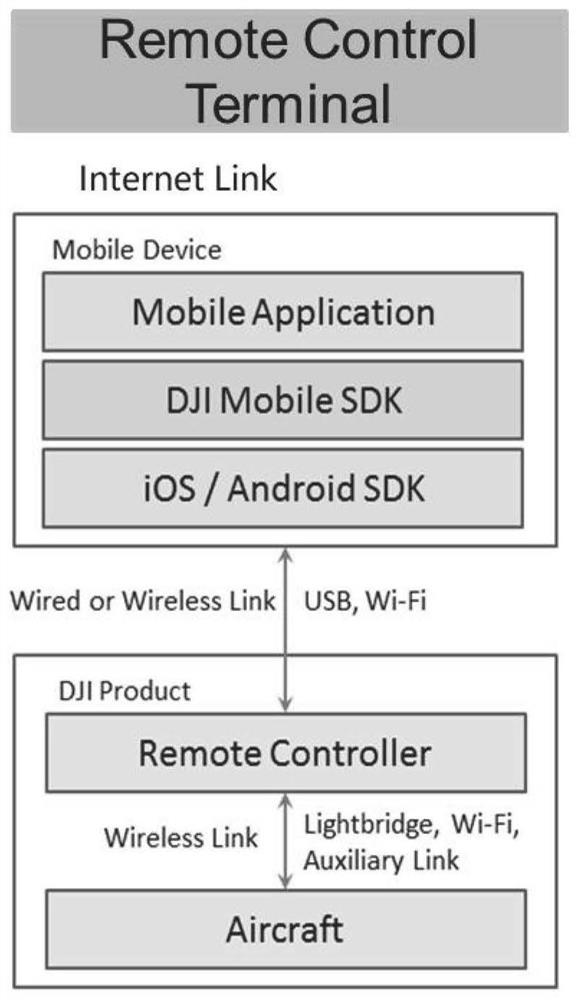

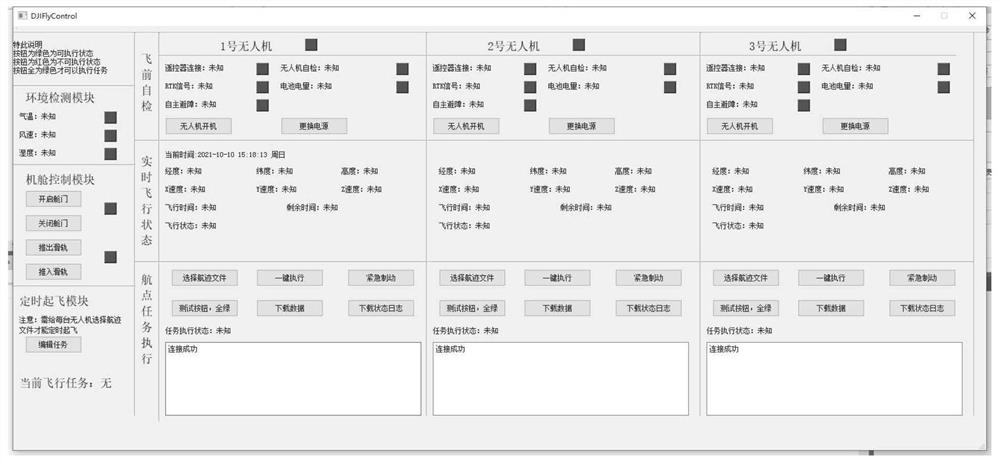

[0048] The present invention provides an automatic inspection system of unmanned aerial vehicle swarms for dam defect detection. By building an unmanned observation station, the unmanned aerial vehicles are networked and intelligently controlled to carry out flight inspection tasks. The observation station includes automatic flight control area, automatic induction charging area, data information transmission area and information storage and processing area. Firstly, according to the selection of UAV and the condition of the dam, taking into account the flight safety distance and the accuracy requirements of disease detection, planning no The human-machine flight trajectory divides the collection area; in the actual inspection process, the automatic flight control area can independently decide the number of UAV take-offs and inspections according to the real-time changes in the dam water level, environmental monitoring results, and the status of the UAV itself. Task: After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com