Method and device for calculating bolt stress caused by additional torque and storage medium

A bolt stress and calculation method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as bolt stress relaxation, bolt stress and fatigue results increase, failure, etc., to achieve strong guidance and improve Stability and the effect of reducing the risk of equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

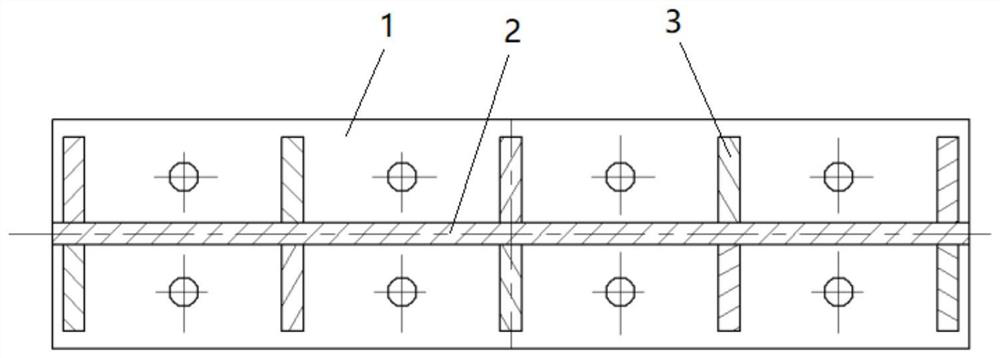

[0057] combine figure 1 and figure 2 As shown, this embodiment provides a method for calculating the bolt stress caused by the additional moment, aiming at the calculation of the bolt stress realized by the saddle support. The saddle support includes a base 1, a web 2 and a rib 3. There is a web 2 running through it horizontally, and the web 2 is vertically arranged with the base 1. There are a plurality of ribs 3 evenly distributed on both sides of the web 2, and a plurality of through holes for bolt installation are processed on the base 1, including the following step:

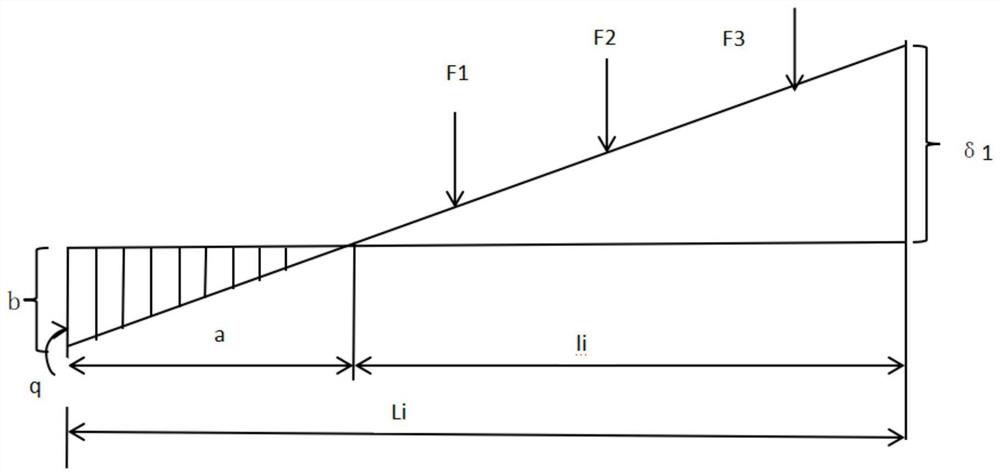

[0058] Step S100, using the principle of similar triangles to obtain the ratio of the deformation δi under the i-th bolt load, the distance li from the center to the i-th bolt load, the distance a from the compression bolt to the center hole, and the axial deformation b of the compression bolt relation:

[0059]

[0060]Step S200: Substituting the distance li from the center to the i-th bolt load, th...

specific Embodiment approach 2

[0107] This embodiment proposes an example of bolt force analysis of saddle supports, and calculates the bolt stresses according to the method of specific embodiment 1, so as to check the effectiveness of this method in the calculation of the bolt stress of saddle supports for petrochemical containers and large steel structures. feasibility.

[0108] 1. Set load data

[0109] Axial force in X direction Fx=45919.6N

[0110] Axial force in Y direction Fy=21944.0N

[0111] Axial force in Z direction Fz=57135.1N

[0112] X direction axial moment Mx=55075222.1N mm

[0113] Axial moment in Y direction My=1245000N·mm

[0114] Axial moment in Z direction Mz=42528316.5N mm

[0115]

[0116] 2. Tensile stress

[0117] Design working condition stress value:

[0118]

[0119] 3. Shear stress

[0120] Design working condition stress value:

[0121]

[0122]

[0123] 4. Calculate the tensile stress generated by My:

[0124]

[0125] Base plate compression length:

...

specific Embodiment approach 3

[0145] Those skilled in the art may use the methods mentioned in the above embodiments, and this embodiment may be provided as a method, a system, or a computer program product. Therefore, the present application may take the form of a complete hardware embodiment, a complete software embodiment, or a combination of software and hardware, and the modules may also be reorganized according to the computer logic structure. Furthermore, the embodiments may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer-usable program code embodied therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com