Preparation method of multi-tab battery cell, multi-tab battery cell and multi-tab battery thereof

A multi-pole ear and cell technology, which is used in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrode manufacturing, etc. The overall energy density and area of the battery are difficult to control, which can save production cycles, improve overall energy density, and reduce process capability requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

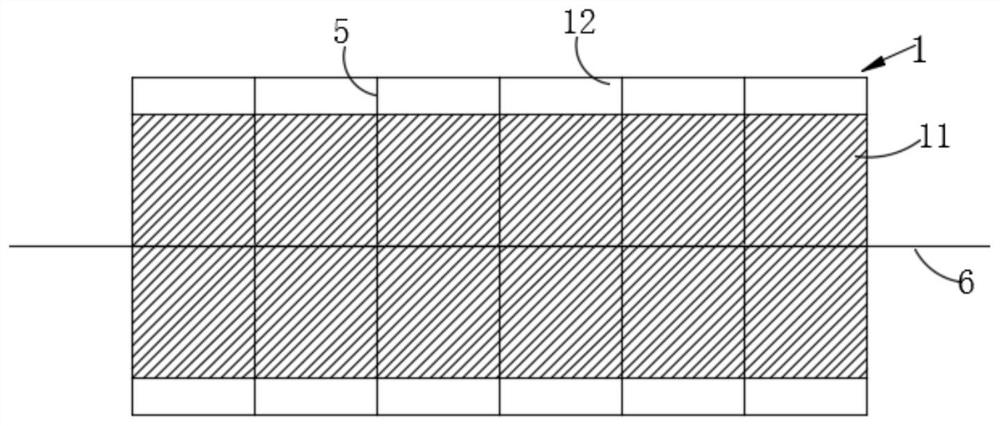

[0045] like Figure 1-7 As shown, what this embodiment 1 provides is the manufacturing process of the positive electrode sheet for the multi-tab battery, which specifically includes the following steps:

[0046] S1. Coating the active slurry: apply the positive electrode active slurry evenly on the surface of the electrode sheet by zebra coating and roll it to make the first positive electrode sheet 1 with blank areas on the upper and lower sides and a dressing area in the middle;

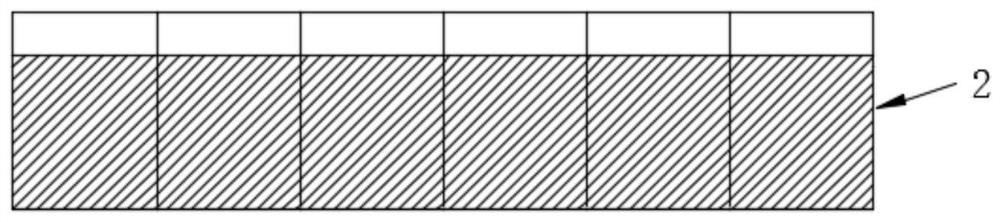

[0047] S2. Pole sheet cutting: the first positive electrode sheet 1 is cut along its transverse midline to obtain two second positive electrode sheets 2;

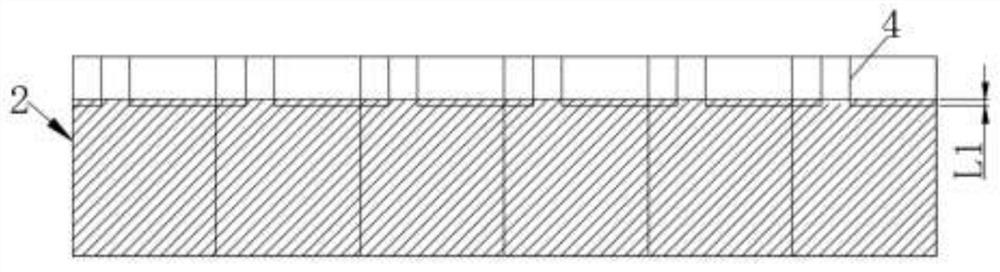

[0048]S3. Tab die-cutting: the edge of the second positive electrode sheet 2 is cut along the first die-cutting line 4 to form a plurality of first tabs 3, wherein the length of the first die-cutting line cut into the dressing area is 2 mm;

[0049] S4. Tab cleaning: Clean the dressing area of the first tab 3, wash off the auxiliary materials...

Embodiment 2

[0061] like Figure 8-14 As shown, what this embodiment 2 provides is the manufacturing process of the negative electrode sheet for the multi-tab battery, which specifically includes the following steps:

[0062] S1. Coating the active slurry: apply the negative electrode active slurry evenly on the surface of the electrode sheet by zebra coating and roll it to make the first negative electrode sheet 7 with blank areas on the upper and lower sides and a dressing area in the middle;

[0063] S2. Pole sheet cutting: the first negative electrode sheet 7 is cut along its transverse midline to obtain two second negative electrode sheets 8;

[0064] S3. Tab die-cutting: the edge of the second negative electrode sheet 8 is cut along the second die-cutting line 10 to form a plurality of second tabs 9, wherein the length of the second die-cutting line cut into the dressing area is 2 mm;

[0065] S4, tab cleaning: clean the dressing area of the second tab 9, wash off the auxiliary ma...

Embodiment 3

[0071] The multi-tab cell provided in this embodiment 3 is formed by winding and / or After lamination, the multiple positive tabs are aligned one by one, and the multiple negative tabs are aligned one by one. Compared with the production process of the conventional multi-tab battery, the dressing area does not need to be guaranteed when the positive and negative electrodes are coated. The single-sided and double-sided alignment reduces the requirements for the process capability of the previous process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com