Primary curing process for high-density tobacco loading of flue-cured tobacco leaves

A high-density, tobacco leaf technology, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of low density of flue-cured tobacco leaves, reduced processing efficiency of flue-cured tobacco leaves, and low energy utilization rate of flue-cured tobacco leaves. The effect of improving energy utilization, improving initial baking quality, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Disclosed is a primary curing process for high-density packaging of flue-cured tobacco leaves, which is applied to an upward-airflow curing barn.

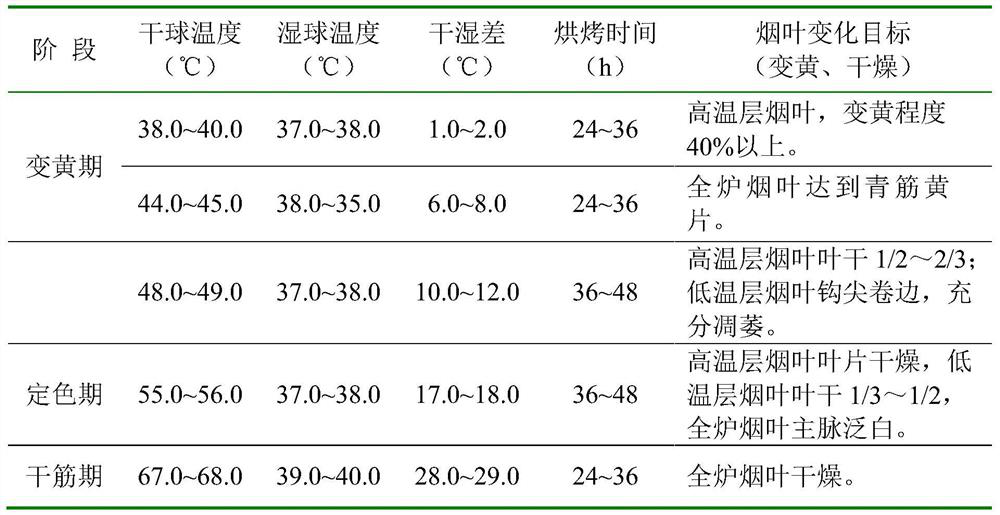

[0018] The steps include the tobacco leaf yellowing period, the tobacco leaf withering period, the tobacco leaf color fixing period and the tobacco leaf drying tendon period.

[0019] A. Yellowing period: ① After the tobacco leaves are loaded into the furnace, the temperature is raised, and the dry bulb temperature is raised from the initial temperature to 39.0°C at a heating rate of 2.0°C / h, and the wet bulb temperature is adjusted to 37.0°C. The temperature is stabilized for 28 hours and baked to Tobacco leaves in the high-temperature layer turn yellow above 40%; ②At a heating rate of 2.0°C / h, raise the dry bulb temperature from 39.0°C to 44.0°C, adjust the wet bulb temperature to 37.0°C, keep the temperature stable for 28 hours, and roast the tobacco leaves in the whole furnace Until the blue veins and yellow slices are r...

Embodiment 2

[0031] The invention discloses a high-density packed primary curing process of flue-cured tobacco leaves, which is applied to a down-air flow curing barn.

[0032] The steps include the tobacco leaf yellowing period, the tobacco leaf withering period, the tobacco leaf color fixing period and the tobacco leaf drying tendon period.

[0033] A. Tobacco leaf yellowing period: ① After the tobacco leaves are loaded into the furnace, raise the temperature, and raise the dry bulb temperature from the initial temperature to 39.0°C at a heating rate of 2.0°C / h, adjust the wet bulb temperature to 37.0°C, stabilize the temperature for 32 hours, and roast Until the tobacco leaves in the high-temperature layer turn yellow above 40%; ②At a heating rate of 2.0°C / h, raise the dry bulb temperature from 39.0°C to 44.0°C, adjust the wet bulb temperature to 38.0°C, keep the temperature stable for 30 hours, and bake until the whole furnace Tobacco leaves reach blue veins and yellow slices.

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com