Silane modified polyether sealing mildewproof glue and preparation method thereof

A technology of silane-modified polyether and anti-mildew glue, which is applied in the direction of polyether adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of endangering human health and non-compliance, and achieve low production cost, The effect of prolonging the service life and making the process feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

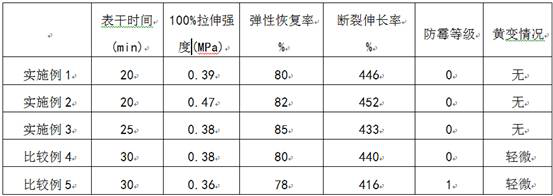

Examples

Embodiment 1

Its preparation method comprises the following steps:

A: 100 parts of silane-modified polyether resin SAX 260, 40 parts of diisononyl phthalate (DINP), 200 parts of active nano-calcium carbonate (UFPCC-306-2 coarse), and 100 parts of heavy calcium carbonate , 40 parts of titanium dioxide, mildew inhibitor BCM: TCCA: IPBC = 0.5 parts were added to the high-speed disperser, the mixture was heated to 90 ℃ in a vacuum state, and dehydrated for 2 hours under the pressure of 0.082 MPa.

[0015] B: After step A is completed, the temperature is lowered to 50° C., 2 parts of vinyltrimethoxysilane, a water scavenger, are added, and the mixture is stirred for 20 minutes. Then the temperature was raised to 80°C in a vacuum state, and dehydrated for 1.5h under a pressure of 0.085MPa.

[0016] C: After step B is completed, the temperature is lowered to 50°C, and 5 parts of water scavenger vinyltrimethoxysilane, silane coupling agent A-1170 (bis(3-trimethoxysilylpropyl)amine) 2 2 parts of ...

Embodiment 2

Its preparation method comprises the following steps:

A: 80 parts of silane-modified polyether resin SAX, 20 parts of S303H, 200 parts of active nano calcium carbonate (UFPCC-306-2 coarse), 50 parts of heavy calcium carbonate, diisononyl phthalate (DINP) 30 parts, 30 parts of diisodecyl phthalate (DIDP), 30 parts of titanium dioxide, antifungal agent BCM: TCCA: IPBC=0.25 parts were added to the high-speed disperser, and the mixture was heated to 90 ℃ in a vacuum state, Under the pressure of 0.085MPa, dehydrate for 2h.

[0018] B: After step A is completed, the temperature is lowered to 50°C, 5 parts of water scavenger vinyltrimethoxysilane is added and stirred for 20min, and then silane coupling agent A-1170 (bis(3-trimethoxysilylpropane) is added. base) amine) 2 parts and N-(β-aminoethyl)-γ-aminopropyl trimethyl (eth) oxysilane 3 parts and catalyst chelated tin U220H 0.5 part, after stirring for 30min, under the pressure of 0.085MPa Stir for 10 minutes, and discharge the ma...

Embodiment 3

100 parts of silane-modified polyether resin, 20 parts of reactive diluent, 200 parts of active nano calcium carbonate, 100 parts of heavy calcium carbonate, 80 parts of diisononyl phthalate DINP, 40 parts of titanium dioxide, mildew inhibitor BCM: TCCA: IPBC=0.3 part, 5 parts of water scavenger vinyltrimethoxysilane, 2 parts of silane coupling agent A-1170 (bis(3-trimethoxysilylpropyl)amine), chelated tin 1 part of U22OH.

[0020] Its preparation method comprises the following steps:

A: Weigh each raw material according to the above ratio, 100 parts of silane-modified polyether resin SAX 260, 250 parts of active nano-calcium carbonate, 60 parts of diisodecyl phthalate (DIDP), 40 parts of titanium dioxide, mildew proof Add BCM:TCCA:IPBC=0.5 part into the high-speed disperser, heat the mixture to 80°C, and stir for 2.5h under the pressure of 0.090MPa vacuum degree.

[0021] B: Cool the mixture obtained in step A to 45°C, then add water scavenger vinyltrimethoxysilane, silane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com