Non-deformable anti-displacement urinary incontinence sling mesh and preparation method thereof

An anti-displacement and urinary incontinence technology, applied in the field of medical devices, can solve the problems of reducing the incidence of postoperative infection, low longitudinal elongation rate, unable to effectively solve the problem of displacement of the sling mesh after operation, etc. The effect of rear displacement risk, stable mesh structure and not easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present application also provides a method for preparing the anti-displacement urinary incontinence sling mesh, comprising the following steps:

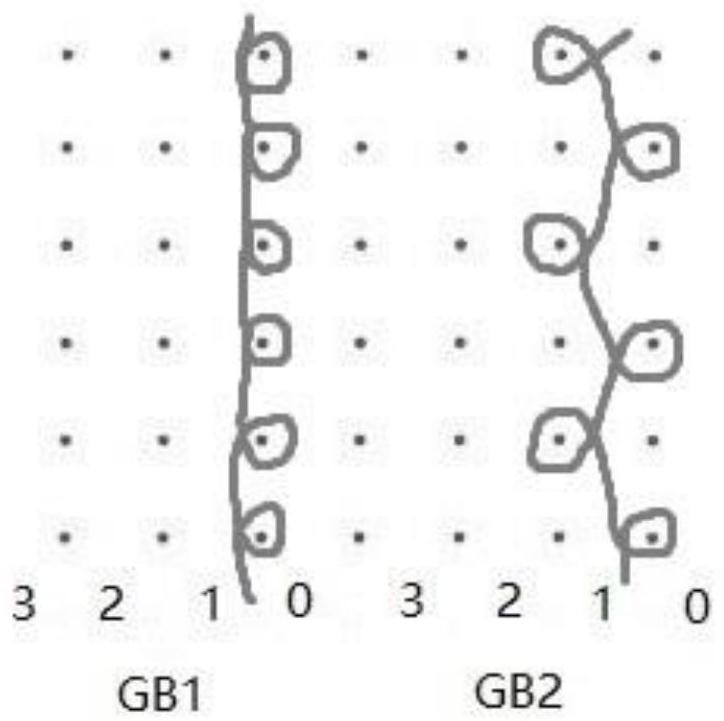

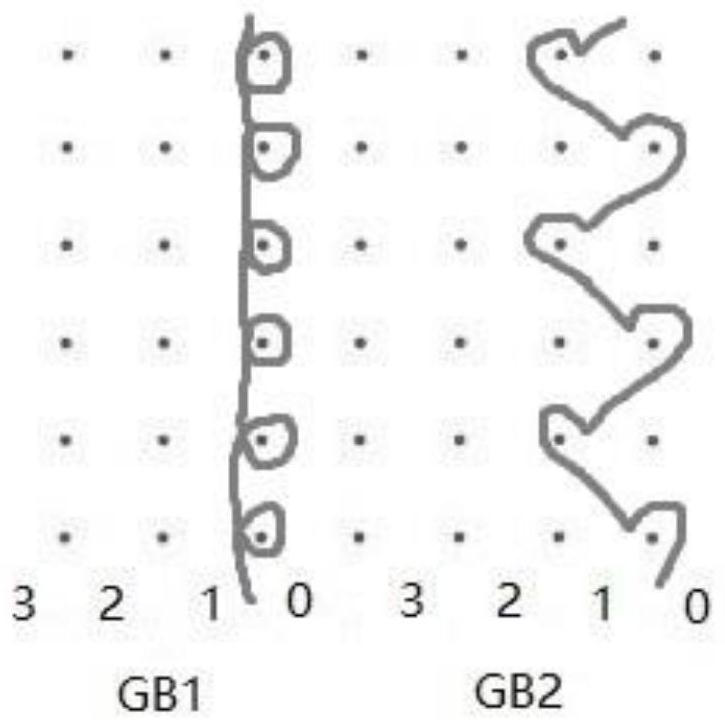

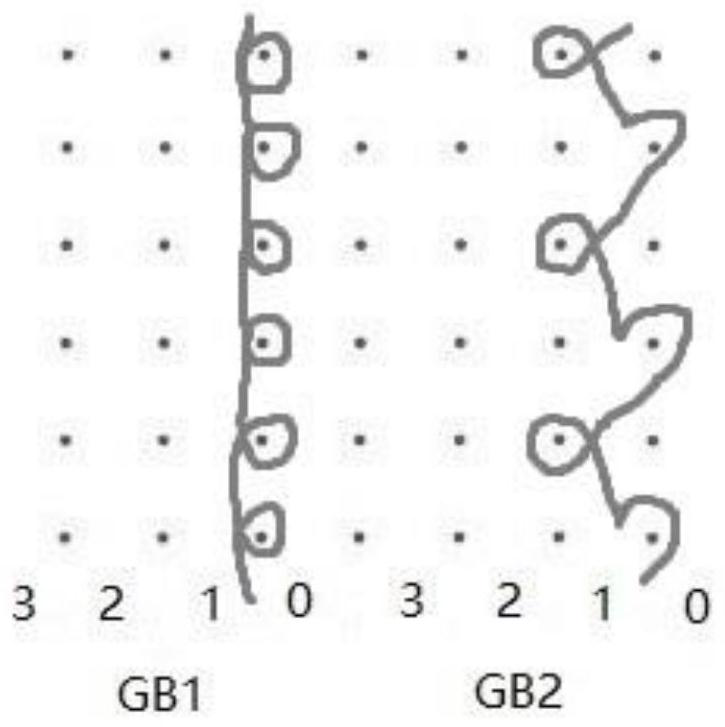

[0027] Install the front and back two guide combs on the warp knitting machine, and the two sets of monofilaments are respectively inserted into the two guide combs, and they are all fully threaded, and each monofilament of the first group is on the corresponding knitting needle Lap the yarn in the longitudinal direction; each monofilament of the second group is lapped and looped in the longitudinal direction on its corresponding two adjacent knitting needles in turn, and weaved to obtain the anti-displacement urinary incontinence sling mesh, the surface of which has Several bumps spaced evenly.

[0028] The urinary incontinence sling mesh provided by the application can significantly reduce the risk of postoperative displacement caused by loose sling, and improve the postoperative cure rate.

[0029] Th...

Embodiment 1

[0049] In this embodiment, medical polypropylene monofilament is selected as a raw material, and its properties are shown in Table 1.

[0050] Table 1 Material selection and performance

[0051] Raw material type diameter (mm) Breaking strength (gf / d) Elongation at break (%) PP monofilament 0.13 5.2 18

[0052] Weaving is carried out by warp knitting machine, and the specific machine process is shown in Table 2.

[0053] Table 2 weaving process parameters

[0054]

[0055] The test method of breaking strength and elongation refers to GB / T 3923.1 "Textile Fabric Tensile Properties Part 1: Determination of Breaking Strength and Elongation at Break (Strip Method)", and the test method of thickness and pore size refers to the pharmaceutical industry standard YY0500 " Cardiovascular implants", the coefficient of kinetic friction refers to FZT 01054-2012 "Test method for friction properties of fabric surface", the test results are as follows:

[005...

Embodiment 2

[0062] This embodiment selects medical polyester monofilament as raw material, and its performance is shown in Table 5.

[0063] Table 5 Material selection and performance

[0064] Raw material type diameter (mm) Breaking strength (gf / d) Elongation at break (%) PET monofilament 0.2 6.8 19

[0065] Weaving is carried out by a warp knitting machine, and the specific machine process is shown in Table 6.

[0066] Table 6 weaving process parameters

[0067]

[0068] The test method of breaking strength and elongation refers to GB / T 3923.1 "Textile Fabric Tensile Properties Part 1: Determination of Breaking Strength and Elongation at Break (Strip Method)", and the test method of thickness and pore size refers to the pharmaceutical industry standard YY0500 " Cardiovascular implants", the coefficient of kinetic friction refers to FZT 01054-2012 "Test method for friction properties of fabric surface", the test results are as follows:

[0069] Table 7 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com