Equidistant cutting device based on building construction and implementation method

A technology for equidistant cutting and building construction, which is applied in the field of distance cutting devices, can solve the problems of increased maintenance cost, impact damage of blocking structures, high requirements for connection strength and structural strength of blocking structures, etc., and achieves the goal of reducing connection strength and structural strength requirements, reduce the probability of damage, and reduce the effect of replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

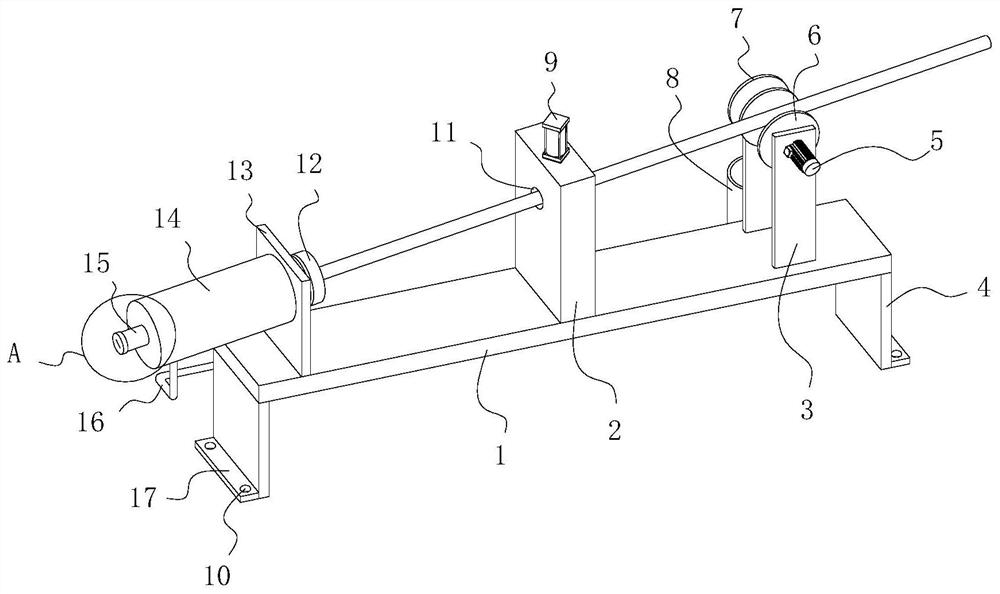

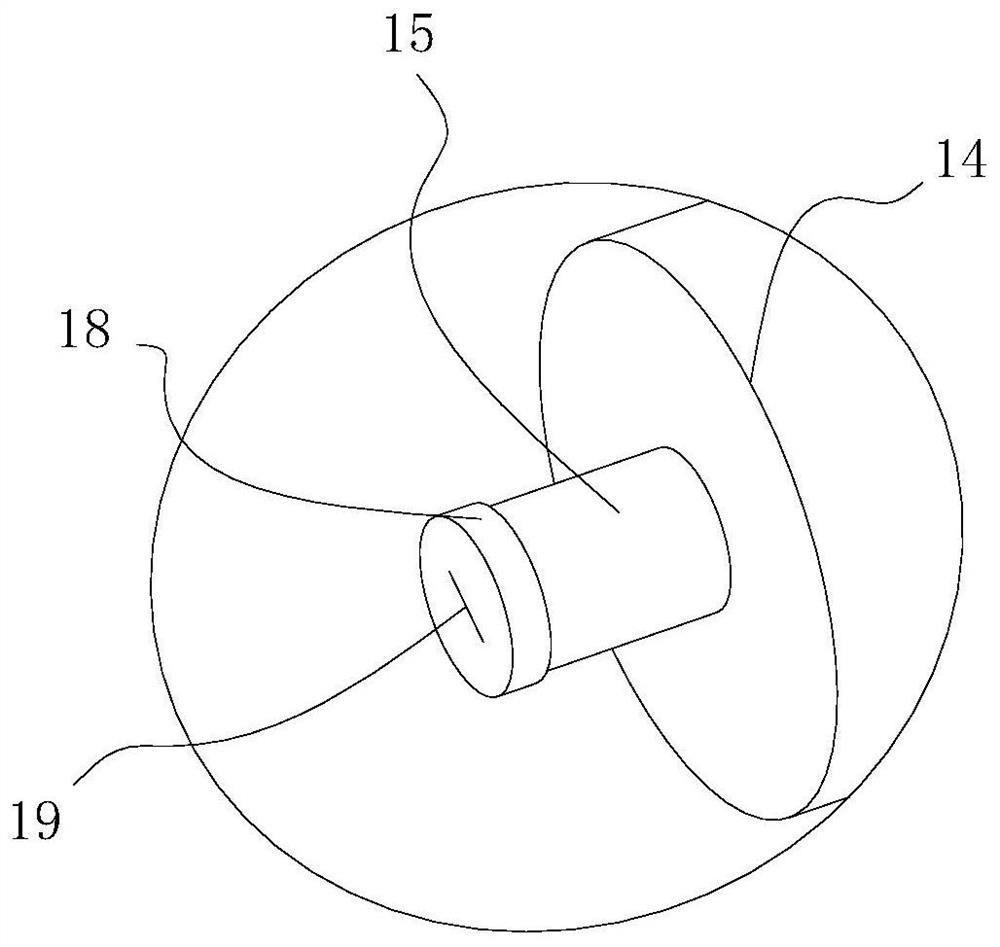

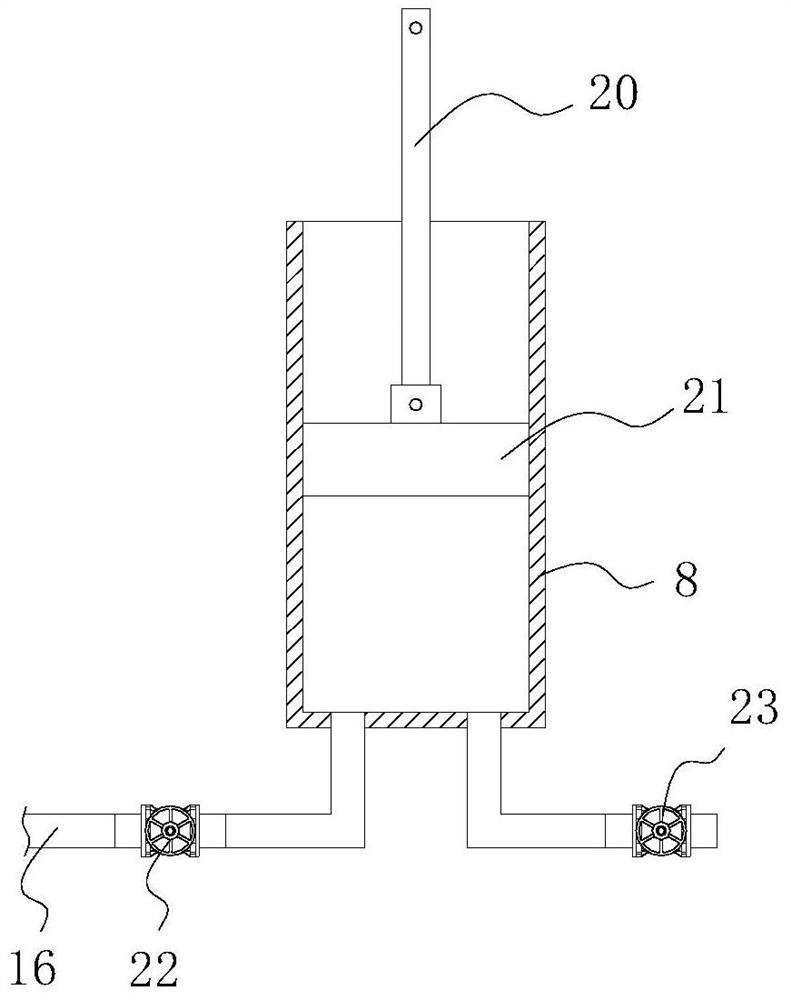

[0043] The specific embodiment: adjust the length of the threaded rod 27 in the threaded pipe 26, so that the distance between the rubber plug 25 and the rubber plate 12 meets the needs of the cutting length of the building steel bar, and then turn the nut 29 to make the nut 29 and the threaded pipe 26 tightly Fitting, it plays the role of preventing the relative rotation of the threaded rod 27 and the threaded column, realizes fine-tuning of the cutting length of the steel bar according to the needs, expands the scope of application, inserts one end of the steel bar in the guide hole 11, and makes the steel bar lapped on the driving wheel 6, when the steel bar hits the rubber plate 12, the rubber plate 12 is squeezed by the steel bar and drives the rubber plug 25 to slide in the air cylinder 14, and then the air in the air cylinder 14 is discharged through the slot 19, so as to realize the buffer protection of the steel bar impact The purpose is to reduce the requirements on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com