Rubber exhaust extruder

An exhaust extruder and extruder technology, applied in the field of rubber extruders, can solve the problems of unstable exhaust effect and low work efficiency, and achieve the effect of easy discharge and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

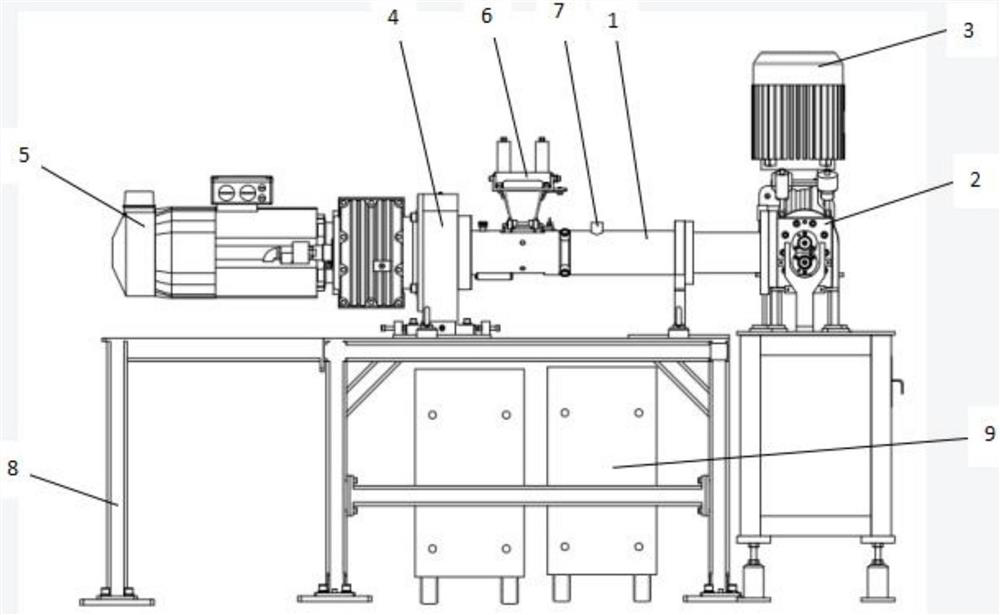

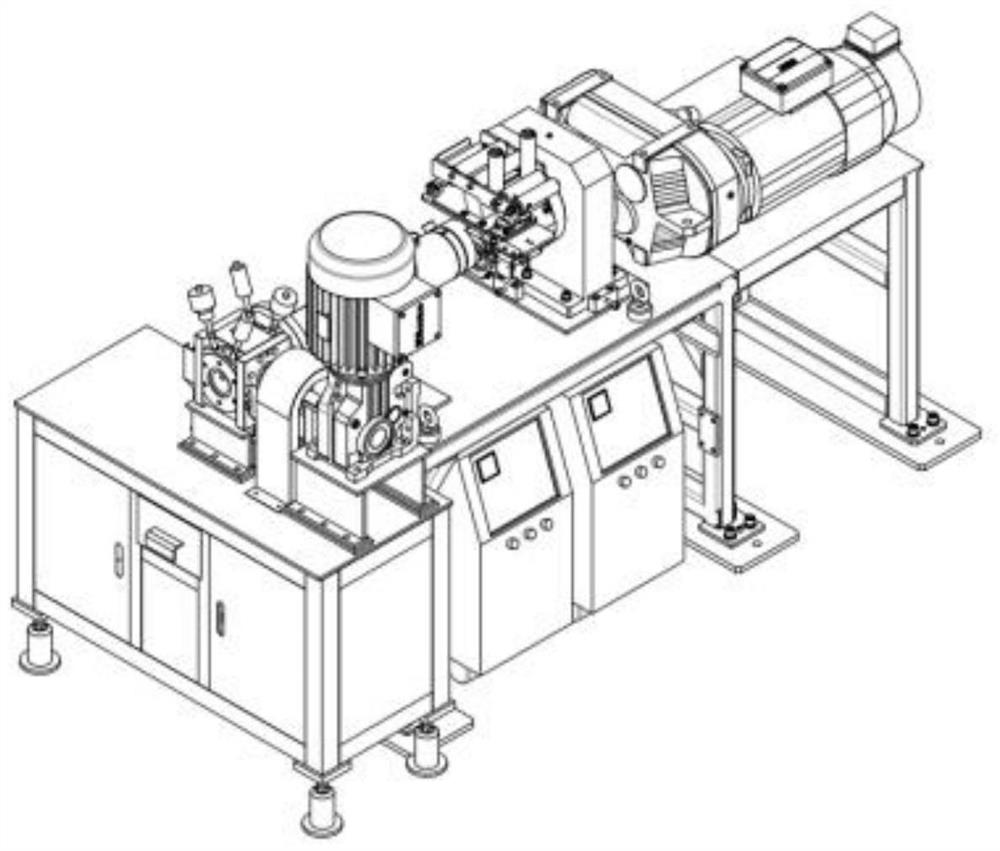

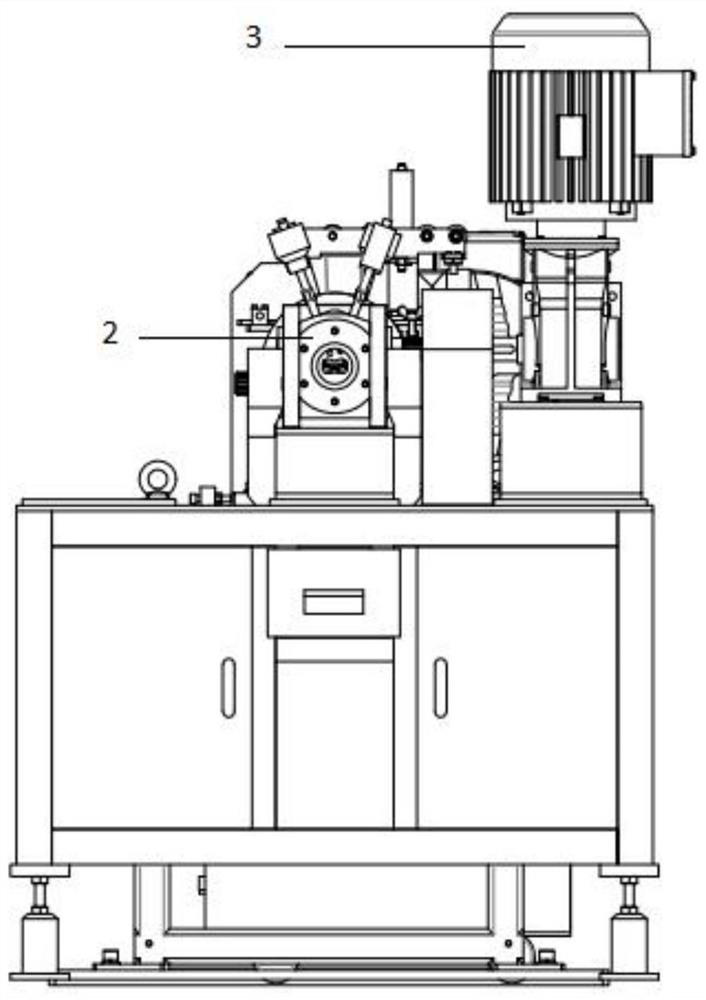

[0015] The main structure of the rubber exhaust extruder involved in this embodiment includes an extruder barrel 1, a gear pump 2, a gear pump motor 3, a reducer 4, a motor 5, a feeding port 6, an exhaust port 7, and a base 8 and mold temperature control box 9; one end of extruder barrel 1 is connected with gear pump 2, gear pump 2 is connected with gear pump motor 3, the other end of extruder barrel 1 is connected with reducer 4, reducer 4 is connected with The motor 5 is connected, the extruder barrel 1 is provided with a feeding port 6 and an exhaust port 7, and the extruder barrel 1, gear pump 2, gear pump motor 3 and reducer 4 are all set on the base of the frame structure 8, the mold temperature control box 9 is arranged under the base 8, and the extruder barrel 1 is electrically connected with the mold temperature control box 9.

[0016] The comparison results of the specific gravity and moisture content of the rubber products prepared by the rubber exhaust extruder inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com