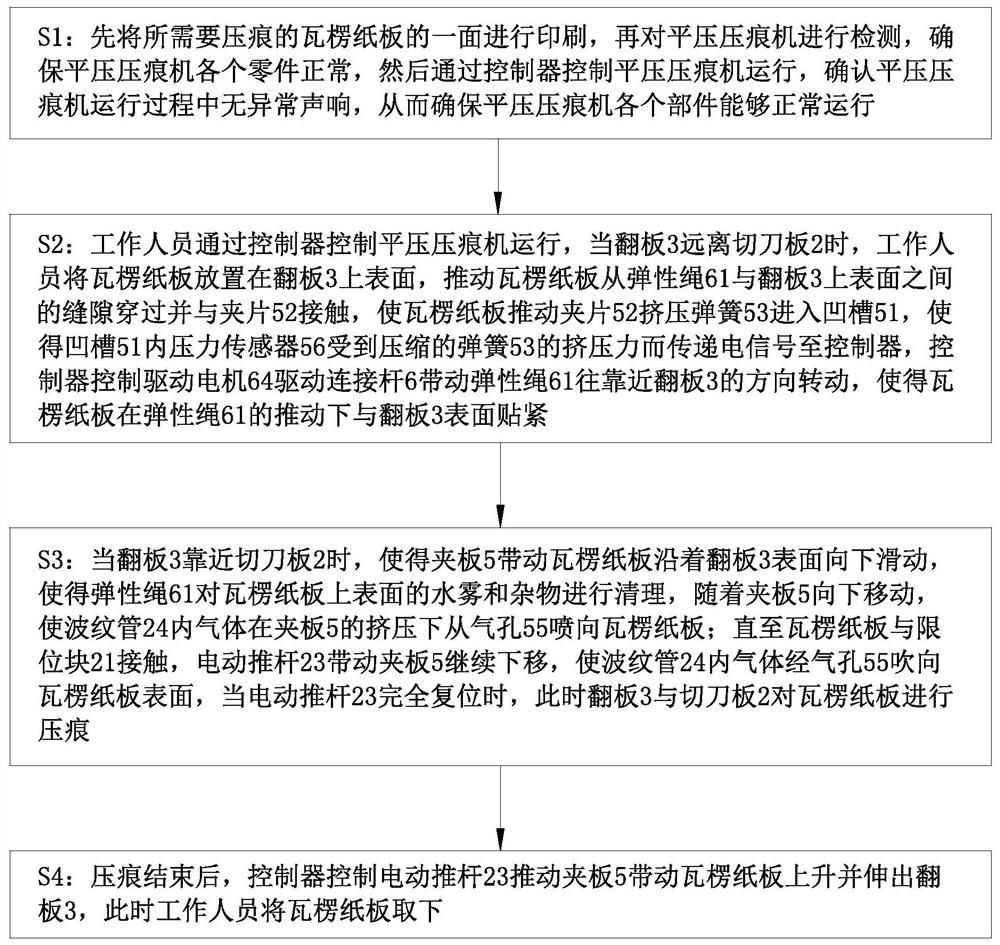

Paper box forming process and paper box production line

A production line and carton technology, used in paper/cardboard containers, papermaking, box making operations, etc., can solve the problem of reducing the quality of corrugated cardboard creasing lines, affecting the indentation effect of flat creasing machines, and reducing the compression resistance of corrugated boxes, etc. problems, to achieve the effect of improving the indentation effect, the accuracy and the compression resistance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

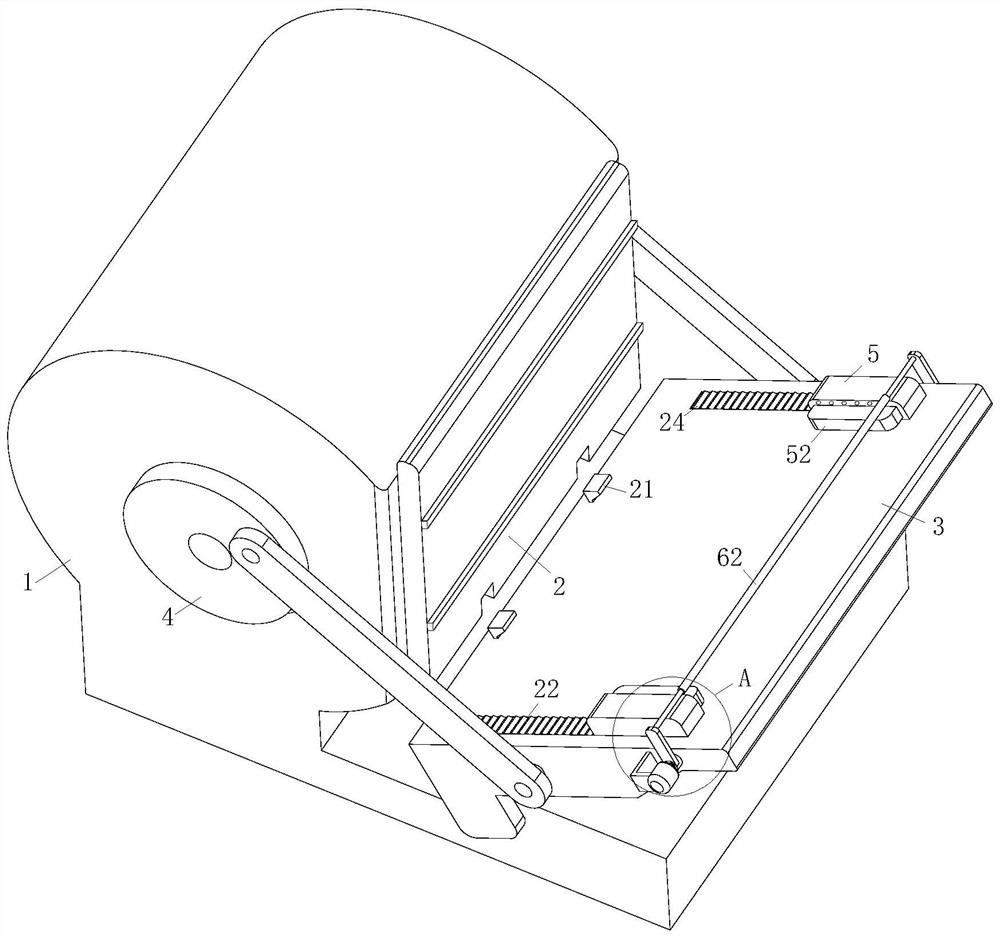

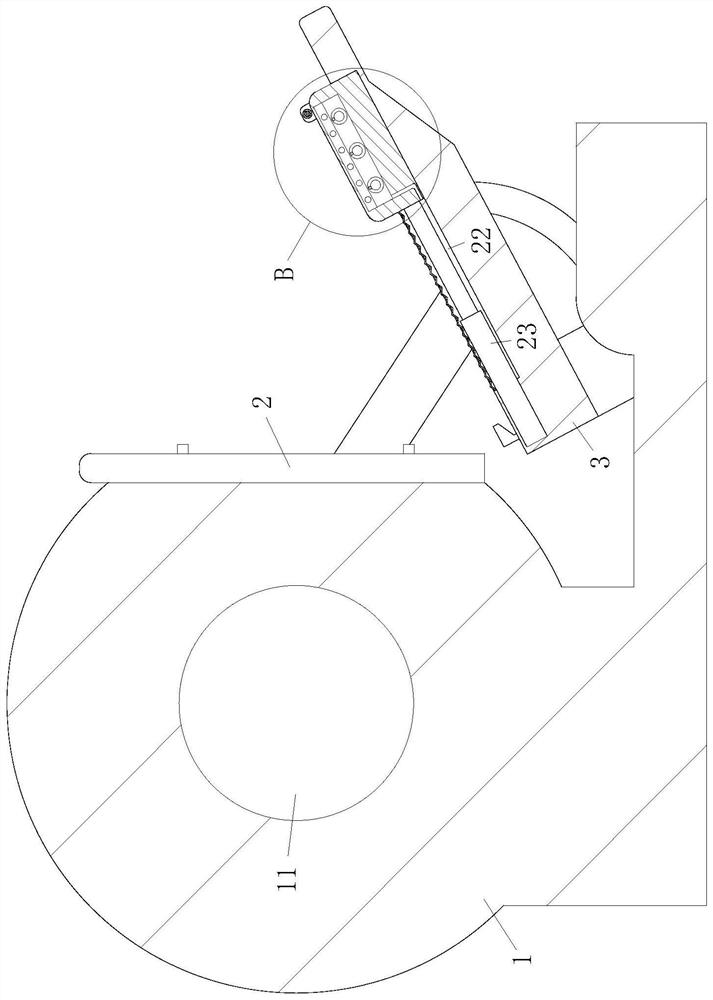

[0036] As an embodiment of the present invention, a chute 22 is provided on the side of the turnover plate 3 close to the cutter plate 2; An electric push rod 23 is installed; during work; because the staff needs to stretch their hands into the flap 3 and take and place the corrugated cardboard, it is easy to cause the danger of pinching their hands, and if the cardboard fails to be taken out, the cardboard will be subjected to secondary indentation. The indentation of the cardboard is deepened, and even the position of the indentation is damaged; therefore, by setting the electric push rod 23 in the present invention, when the turning plate 3 is kept away from the cutter plate 2, the electric push rod 23 pushes the splint 5 to slide upward along the chute 22, when the sliding When reaching the other end of the chute 22, the staff will jam the corrugated cardboard between the two splints 5. At this time, the opening between the turning plate 3 and the cutter plate 2 is the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com