Conveying line roller capable of limiting driving force

A conveying line and driving force technology, which is applied in the directions of conveyor objects, rollers, transportation and packaging, etc., can solve the problems of heavy workload, attenuation of spring force, and heavy burden of conveying line maintenance, to simplify the mechanism and simplify the transmission. mechanism, the effect of reducing the intensity of maintenance work and the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0028] In the present invention, unless otherwise clearly specified and limited, terms such as "installation", "connection", "connection" and "fixation" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection , or integrated; it may be mechanically connected or electrically connected; it may be directly connected or indirectly connected through an intermediary, and it may be the internal communication of two components or the interaction relationship between two components, unless otherwise specified limit. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

[0029] In the present i...

Embodiment 1

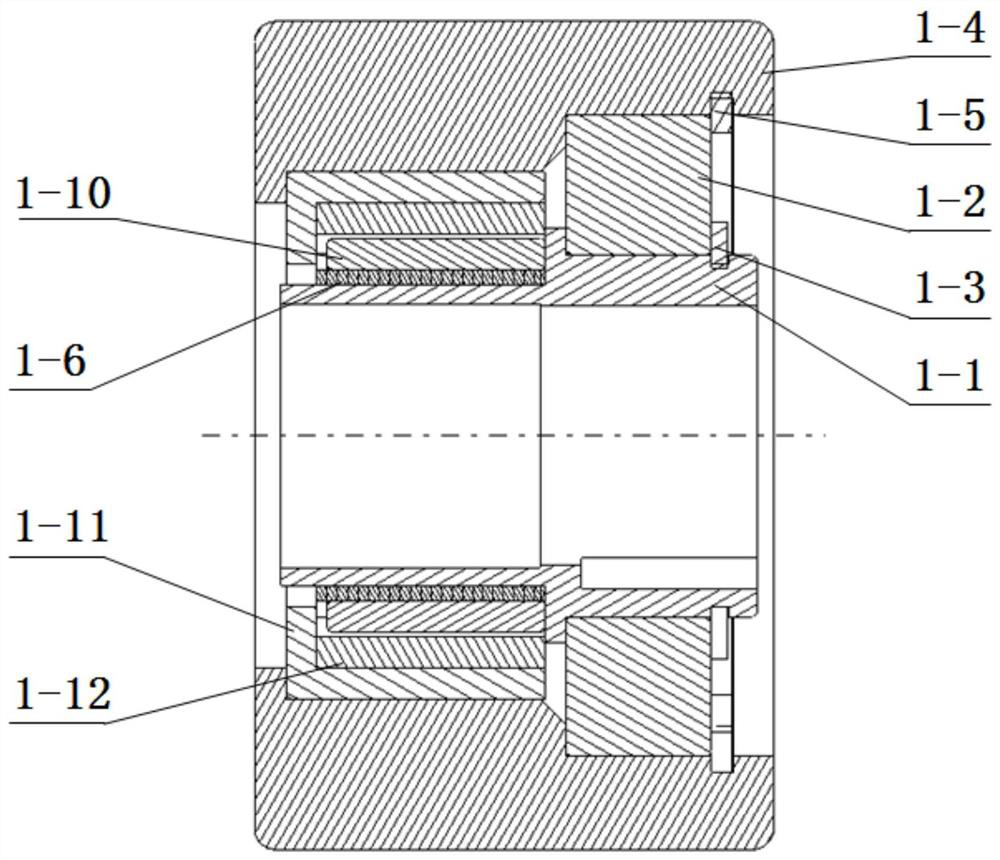

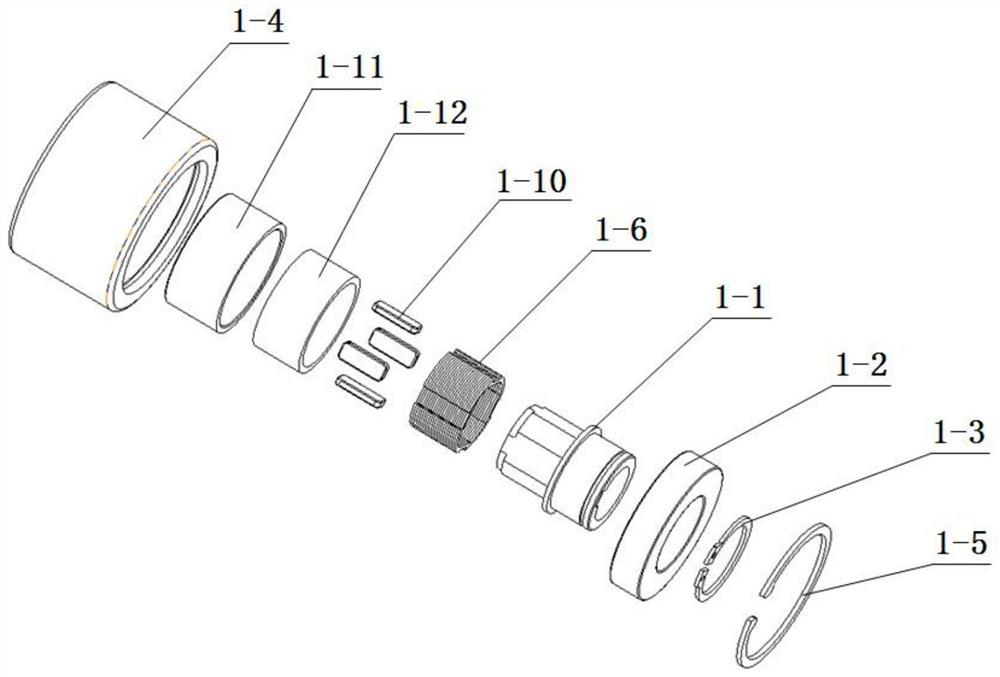

[0032] Such as figure 1 As shown, this embodiment provides a conveyor line roller with limited driving force, which is used to support the material pallet on the automatic roller conveyor line and drive it to move horizontally, which can limit the driving force without friction and wear, and contributes to Simplify the transmission mechanism of the roller conveyor line.

[0033] A roller for a transmission line that limits driving force, including a hollow shaft 1-1, a rolling bearing 1-2, an outer ring of the roller 1-4, an elastic retaining ring 1-5 for holes, a magnet bracket 1-6, and a spacer 1 -11 and iron core 1-12;

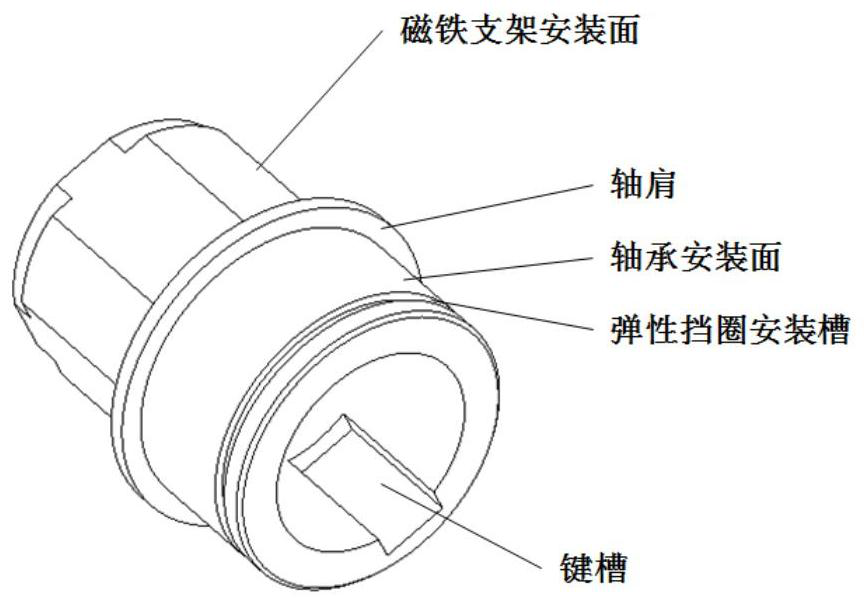

[0034] Such as image 3 and Figure 4 As shown, the hollow shaft 1-1 is introduced in detail. The inner hole of the hollow shaft 1-1 is slidingly fitted with the roller installation shaft. , the rolling bearing 1-2 is installed on the bearing installation surface, a circle of shaft shoulder and hollow shaft retaining ring installation groove are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com