Cantilever type three-axis lead screw movement sliding table

A cantilever, sliding table technology, applied in the measurement of vibration, electric components, transmission devices, etc., can solve the problems of lubricating oil condensation and dripping, inaccurate installation, affecting equipment components, etc., to solve stagnation, alleviate jitter, and save money The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

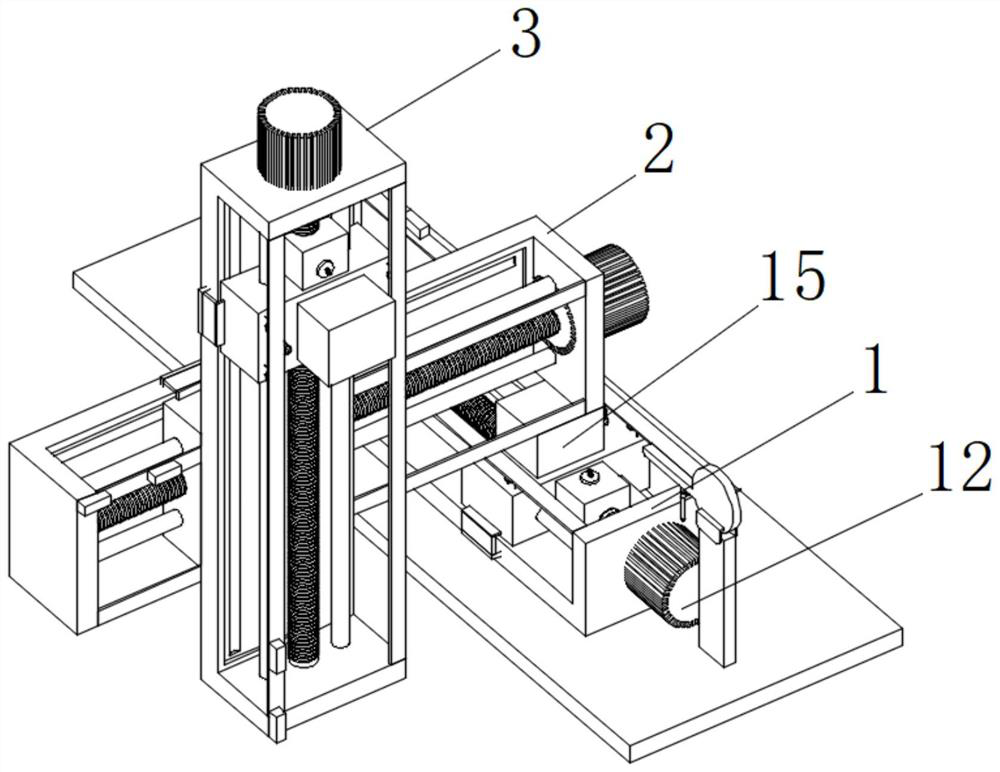

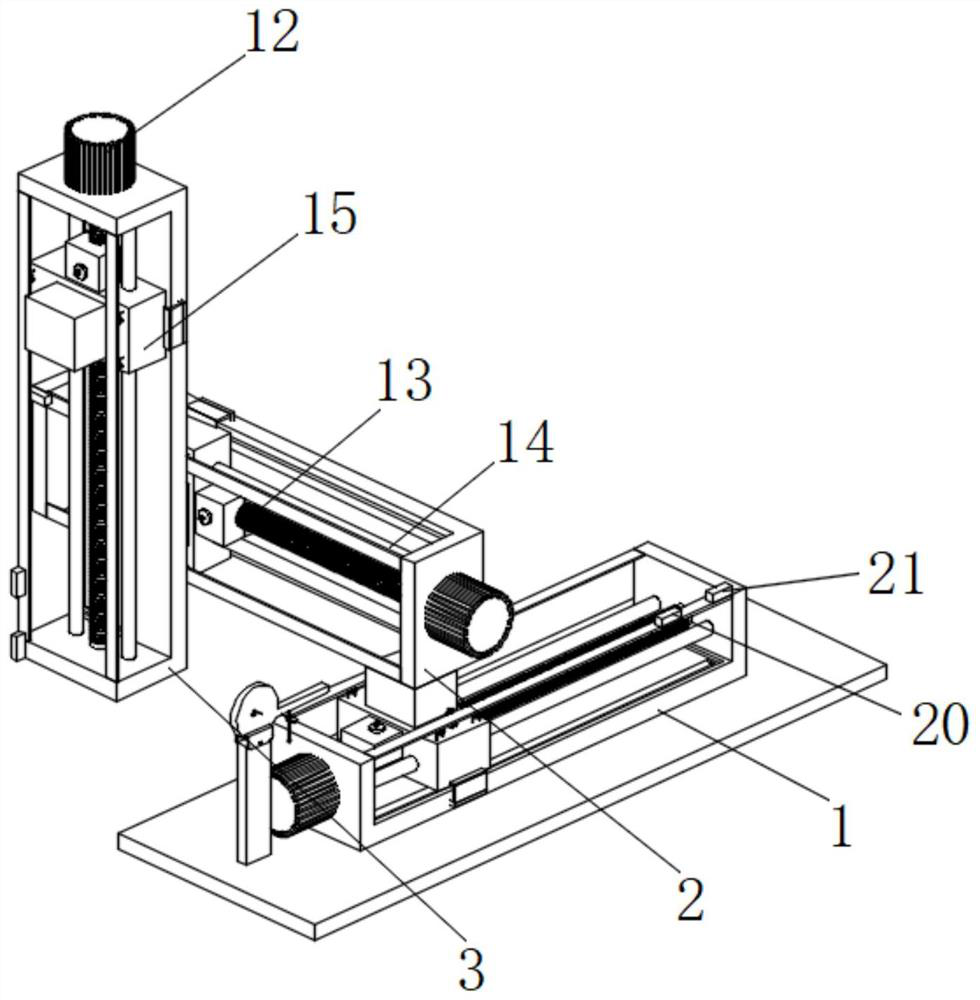

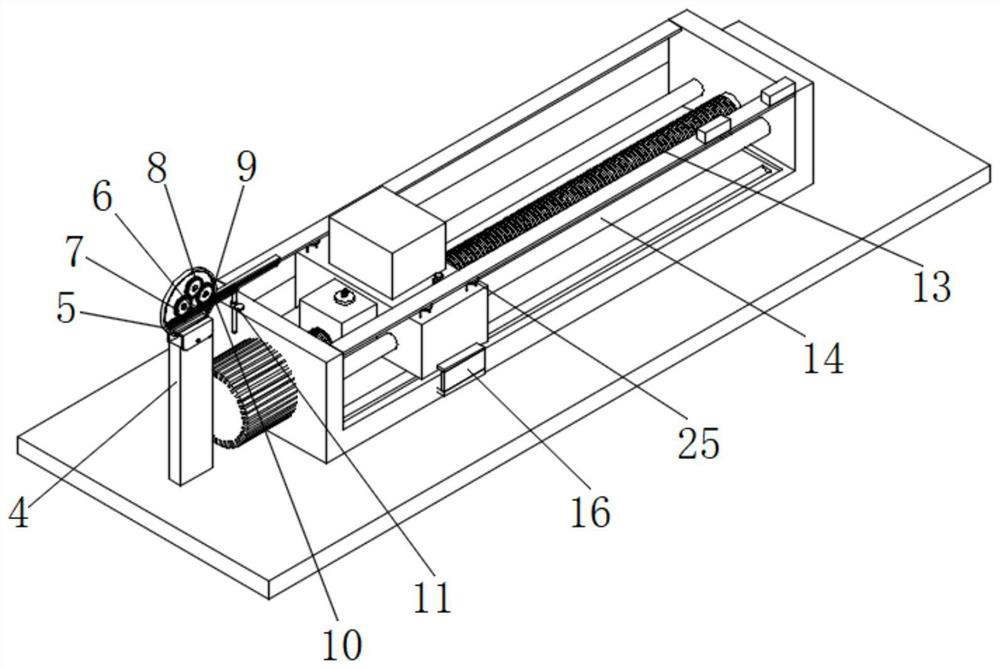

[0031] see figure 1 , figure 2 to, image 3 and Figure 4 , the present invention provides a technical solution: a cantilevered three-axis screw motion slide table, including a Y-axis motion slide table 1, an X-axis motion slide table 2 and a Z-axis motion slide table 3, a Y-axis motion slide table 1, an X-axis motion slide table The shape and function of the table 2 and the Z-axis motion slide table 3, and the connection methods with other structures are the same. The front side of the Y-axis motion slide table 1 is provided with a mounting plate 4, and a calibration shell 5 is installed on the mounting plate 4. Calibration The inner cavity of the housing 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com