Novel boiler manned maintenance platform traction winch braking device

A technology of braking device and traction winch, applied in the direction of hoisting device, etc., can solve the problems of insufficient speed, potential safety hazards, and potential safety hazards, and achieve the effect of large braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

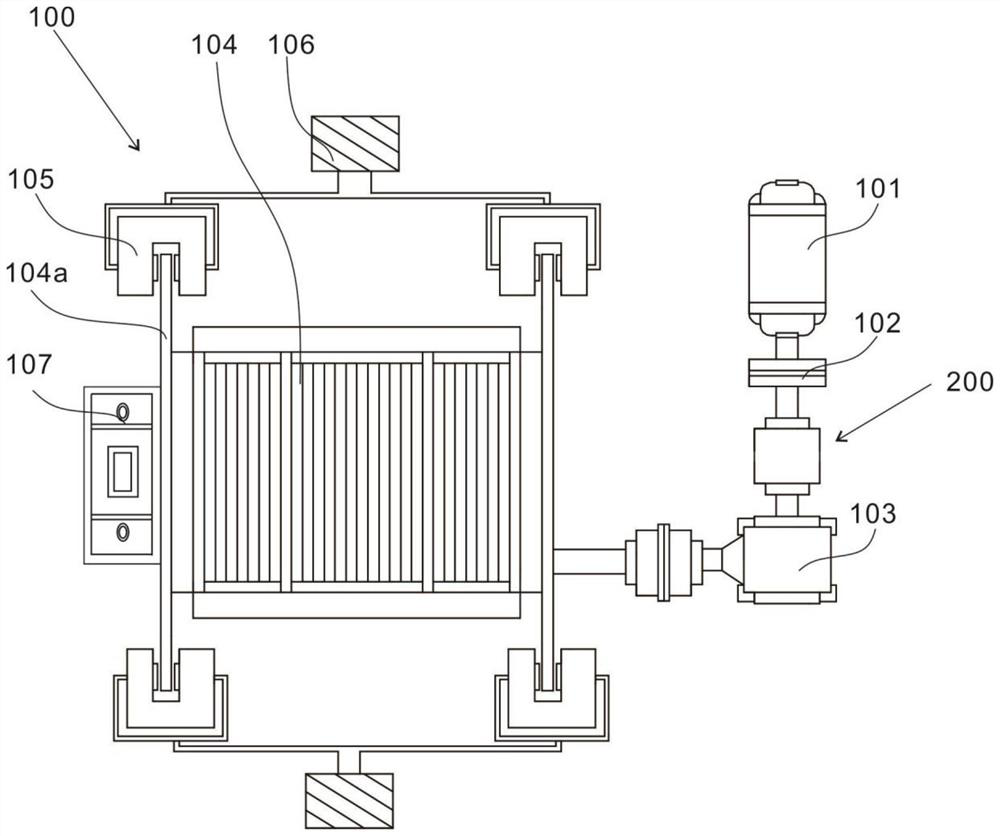

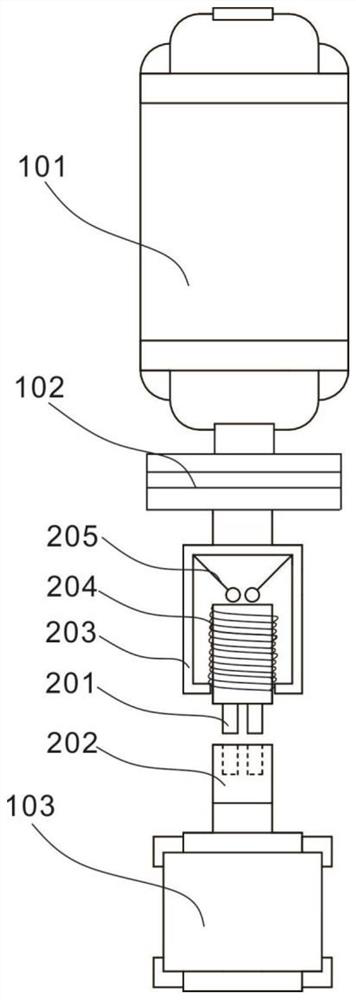

[0026] refer to figure 1 with figure 2 , a novel boiler manned maintenance platform traction winch braking device includes a braking device 100 and a connecting device 200 .

[0027] The braking device 100 can make the moving or running unit achieve the purpose of deceleration or parking, which includes a motor 101 for providing power; a working brake 102 arranged on the main shaft of the motor 101 for emergency braking; The speed reducer 103 connected to the motor 101, the speed reducer 103 mainly plays the role of reducing the rotating speed of the prime mover; the reel 104 connected with the reducer 103, the reel 104 is used to wind the wire rope and transmit power; and the reel 104 A plurality of disc brakes 105 are connected; and a hydraulic station 106 connected with the disc brakes 105 is used for emergency braking of the disc brakes 105 .

[0028] When the winch needs emergency braking, the motor 101 is turned off, the working brake 102 is used for emergency braking...

Embodiment 2

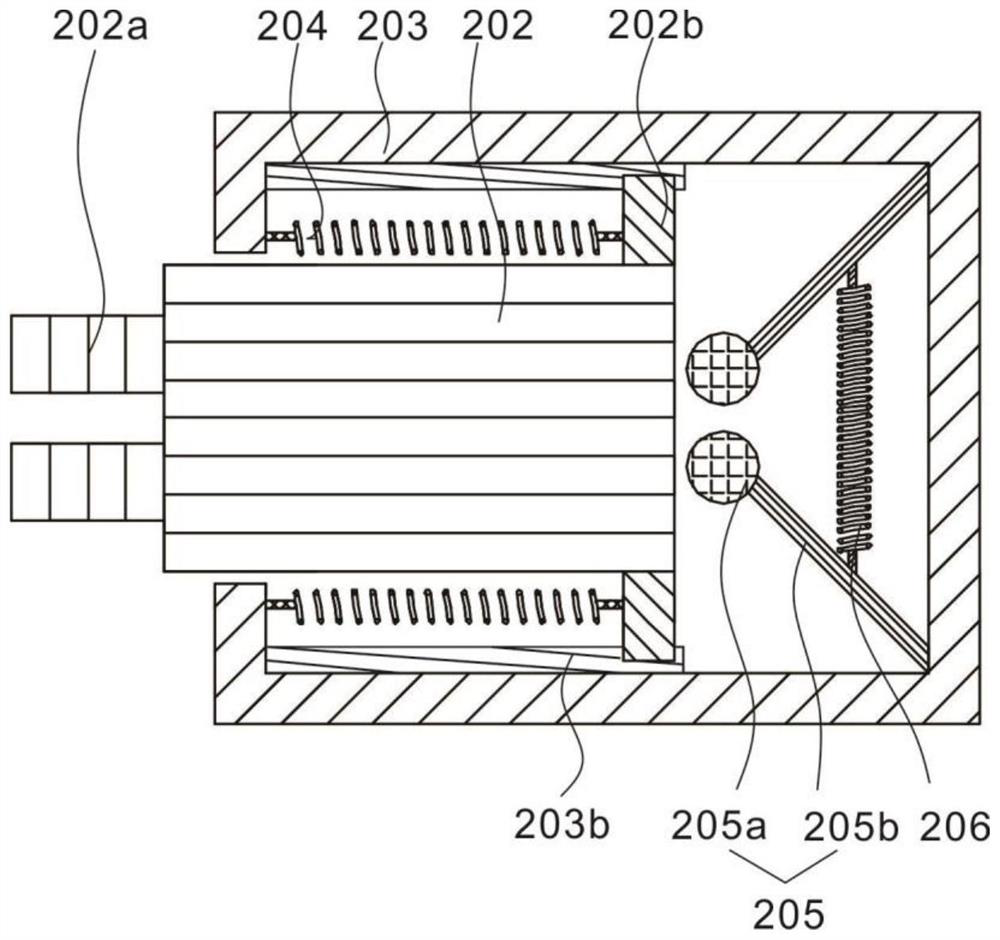

[0033] refer to image 3 with Figure 4 , this embodiment is different from the first embodiment in that: the connecting device 200 is more stable when working.

[0034] One end of the first shaft coupling 201 close to the second shaft coupling 202 is provided with four connection grooves 201a, and the four connection grooves 201 are equidistantly arranged on the first shaft coupling 201; the second shaft coupling 202 is adjacent to the second shaft coupling 202 One end of a coupling 201 is provided with four connecting blocks 202a, which are equidistantly arranged on the second coupling 202; the connecting blocks 202a are inserted in the connecting groove 201a.

[0035]Preferably, the cross section of the connection block 202a and the connection groove 201a is a circle, the outer wall of the connection block 202a is smooth, the inner wall of the connection groove 201a is smooth, and the notch cross section of the connection groove 201a is slightly larger than the cross secti...

Embodiment 3

[0041] refer to Figure 5 , this embodiment is different from the above embodiments in that: the braking force is greater, and the failure of one of the braking units will not lead to the failure of the entire brake

[0042] Brake discs 104a are provided at both ends of the reel 104, and four disc brakes 105 are arranged symmetrically on both sides of the two brake discs 104a; when emergency braking occurs, the force of the disc brakes 105 will The position above the brake frying pan 104a is not on the main body of the reel 104, which can greatly reduce the heat load and mechanical friction on the surface of the reel 104.

[0043] Further, the disc brake 105 is provided with a contact block 105a, a disc spring 105b and a hydraulic cylinder 105c connected in sequence, the contact block 105a is in contact with the brake disc 104a, and the hydraulic cylinder 105c is connected with the hydraulic station 106 . The braking force of the hydraulic cylinder 105c is far greater than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com