Cambered surface friction cocoon silk gathering device and cocoon silk gathering method

A cocoon thread and curved surface technology, which is applied in the field of curved surface friction cocoon thread gathering devices, can solve the problems of cocoon silk cohesion performance differences, inability to fully realize factory automatic production, and affect the quality of raw silk, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

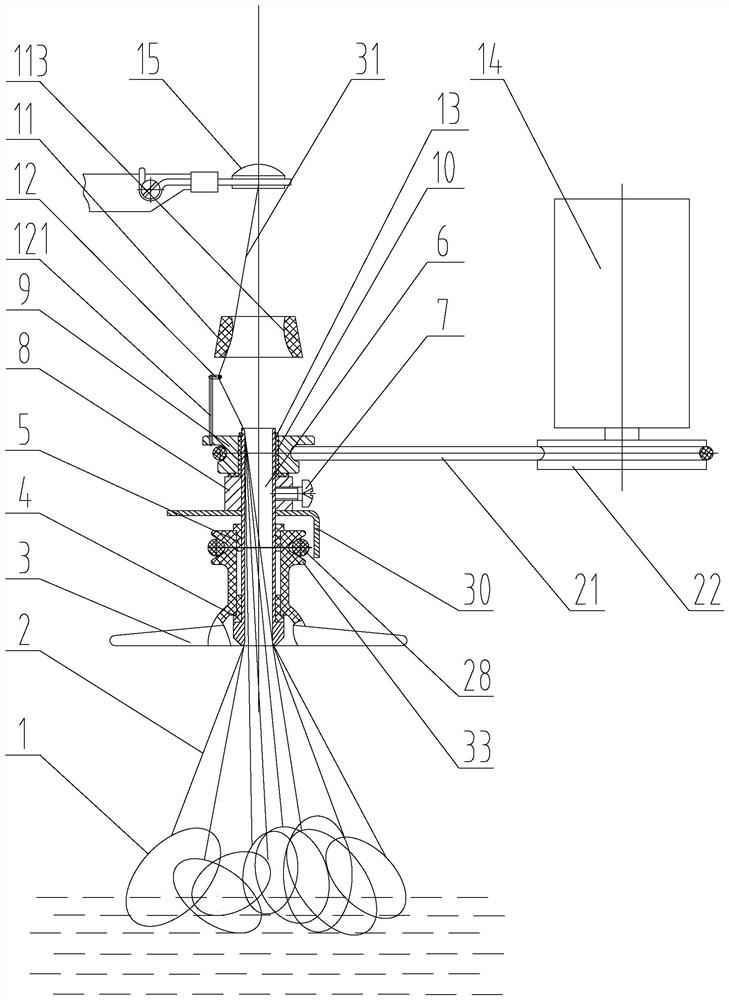

[0017] With reference to the accompanying drawings, the present invention provides an arc surface friction cocoon yarn gathering device, which includes a gathering friction part, and the gathering friction part adopts a friction sleeve 11 with a friction arc surface on the inner wall, and the gathering friction part is located between the thread pipe 6 and the Between the setters 15; between the thread pipe 6 and the accumulation friction part, an accumulation guide part is set. The component makes the cocoon thread 2 deviate from the center line of the thread pipe 6 at the upper end exit of the thread pipe and cooperates with the thread collector 15 above it, so that the cocoon thread touches the inner wall friction arc of the friction sleeve 11 with a friction arc surface on the inner wall On the surface 113, the accumulating and guiding part that makes a circular motion drives the cocoon thread to move in the circumferential direction relative to the inner wall friction arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com