Coal quantity compensation control method based on start and stop of direct-fired pulverizing systems

A pulverizing system and compensation control technology, which is applied in the combustion method, combustion control, and fuel supply adjustment, etc., can solve the problems of different combustion efficiency of boilers and poor practical practicability in production practice, so as to improve safety, reliability and fit. High, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

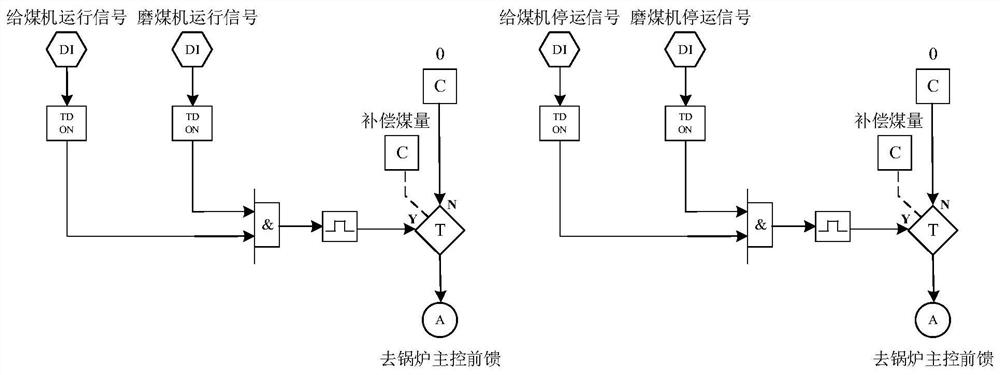

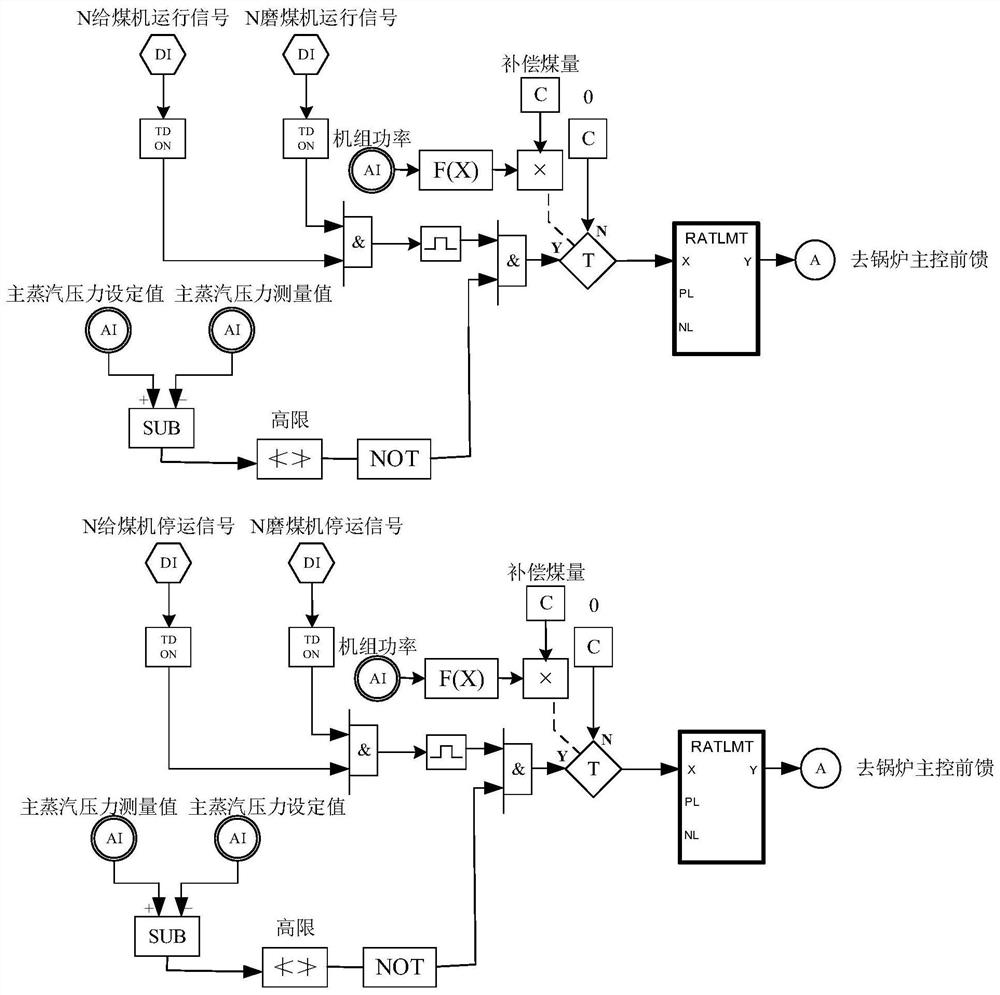

[0078] see figure 2 , the present invention provides a logic control method for starting and stopping coal quantity compensation in a pulverizing system. The first embodiment is suitable for supercritical and ultra-supercritical 1000MW units. The control function of the main steam pressure of the unit is the sliding pressure curve of the full load section. Take the compensation coal amount control logic for the start and stop of the Nth set of pulverizing system as an example, including:

[0079] Step S1: Obtain the operation signals of the coal feeder and coal mill of the generator set (generally, the generator set will be equipped with six sets of pulverization systems, and each pulverization system includes a coal feeder and a coal mill), and set an appropriate delay Time (1-3 seconds), to avoid the logic malfunction caused by abnormal changes in the operation signals of the coal feeder and coal mill.

[0080] Step S2: Obtain the outage signal of the coal feeder and coal ...

Embodiment 2

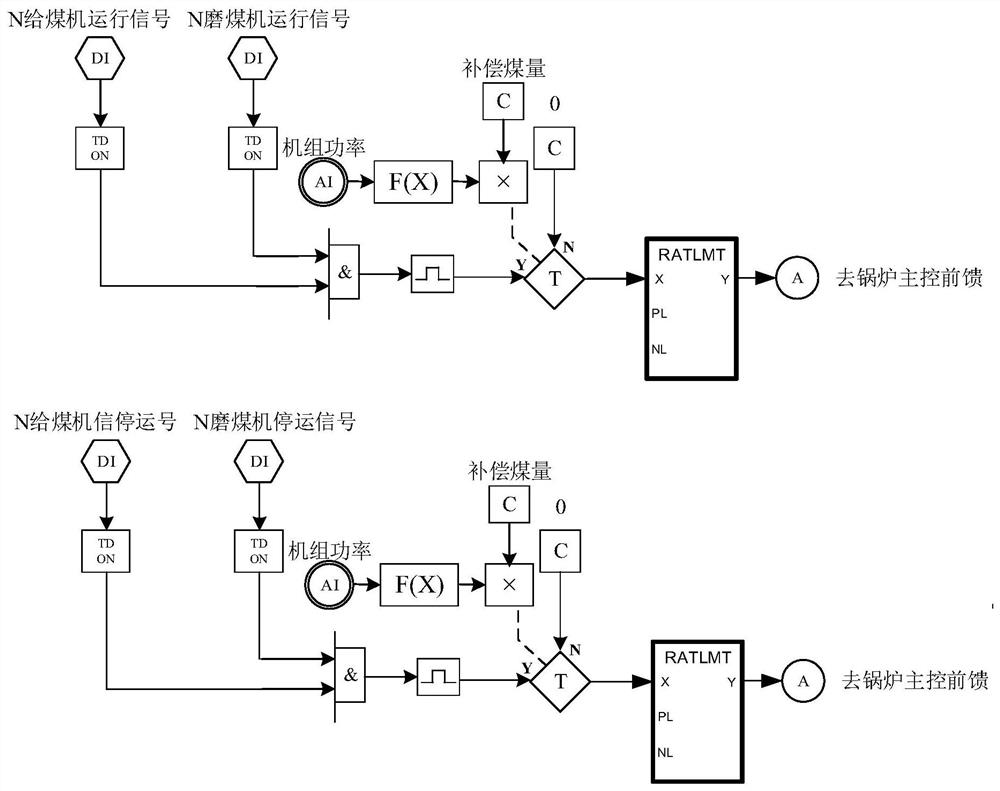

[0087] see image 3 , is the second embodiment of a logic control method for starting and stopping coal quantity compensation of a pulverizing system provided by an embodiment of the present invention, and is applicable to a 600MW unit whose main steam pressure function has a constant pressure curve setting. include:

[0088] Step S1: Obtain the operation signals of the coal feeder and coal mill of the generator set (generally, the generator set will be equipped with six sets of pulverization systems, and each pulverization system includes a coal feeder and a coal mill), and set an appropriate delay Time (1-3 seconds), to avoid the logic malfunction caused by abnormal changes in the operation signals of the coal feeder and coal mill.

[0089] Step S2: Obtain the outage signal of the coal feeder and coal mill of the generator set (generally, the generator set will be equipped with six sets of pulverization systems, and each pulverization system includes a coal feeder and a coa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap