Raw material rapid drying device for log furniture production

A technology of rapid drying and drying device, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of reducing furniture efficiency, material deformation, external drying operation of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

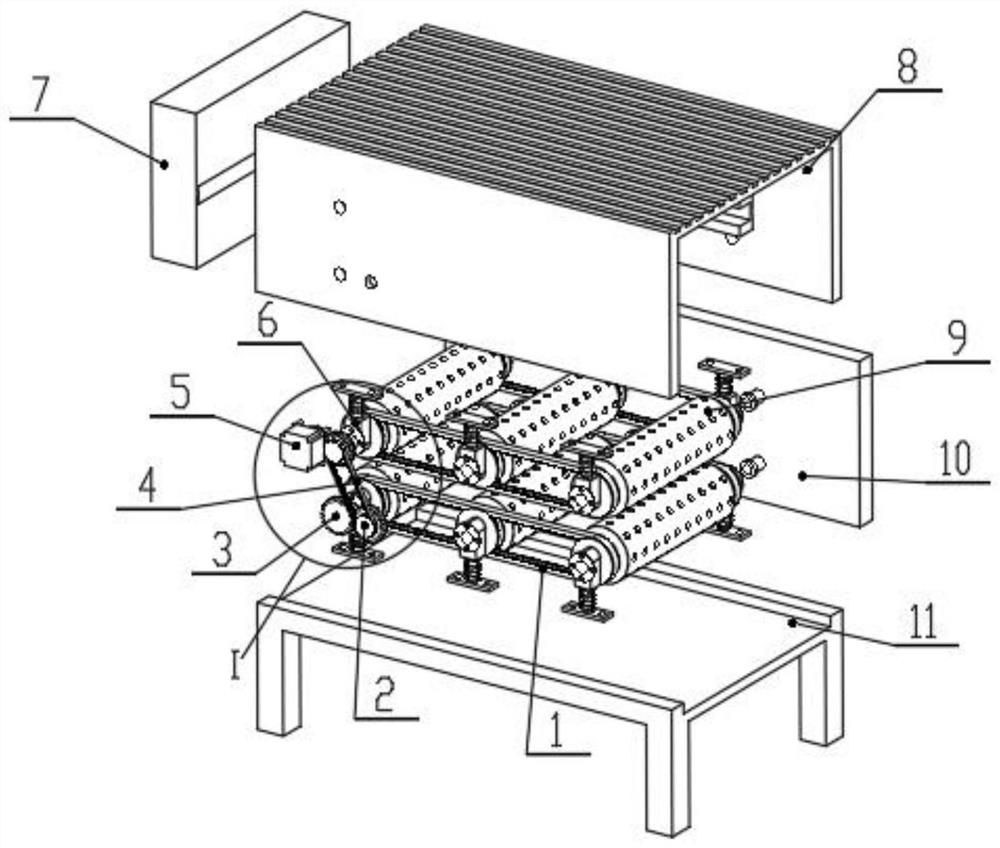

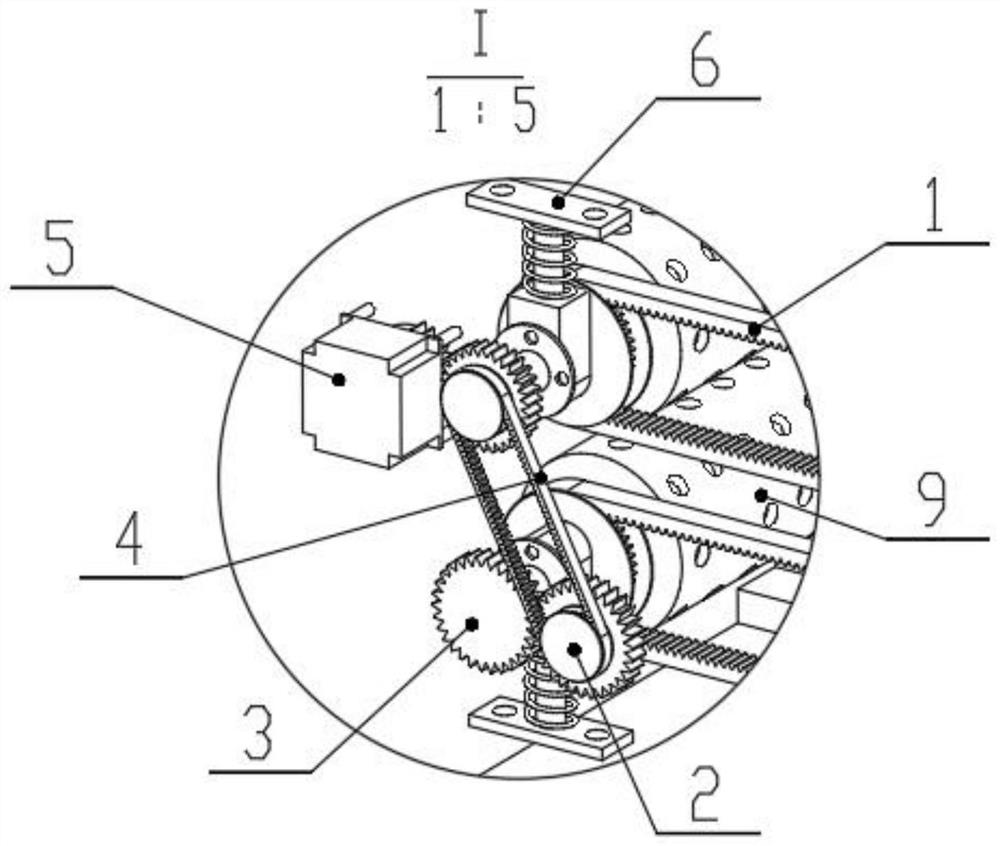

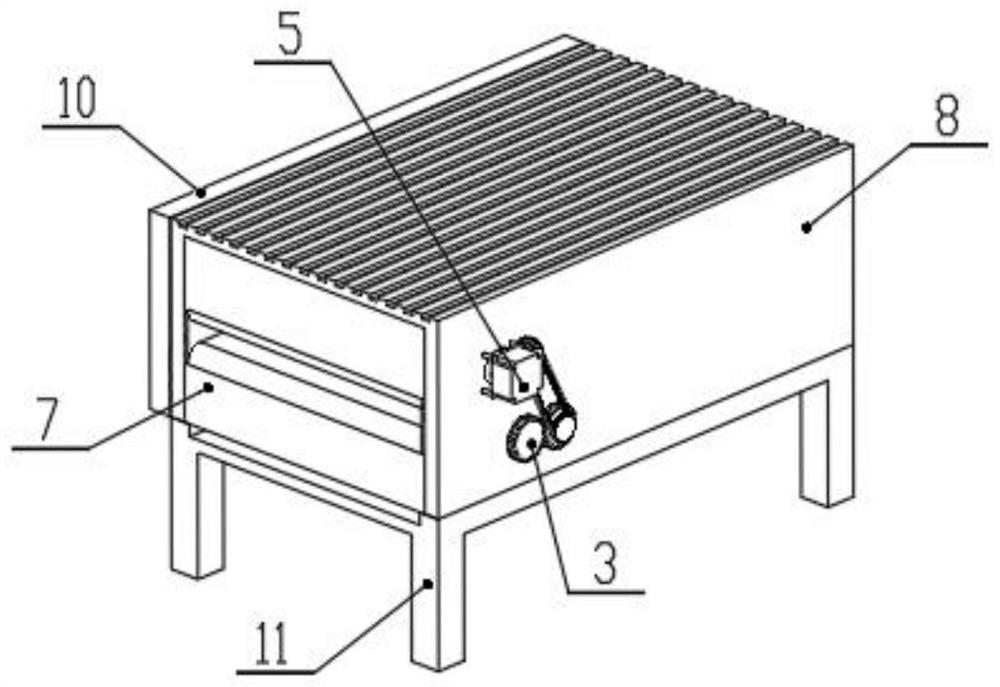

[0040] like Figure 1-2 As shown, a raw material rapid drying device for the production of log furniture, including a toothed belt 1, a toothed pulley 2, a fixed gear 3, a connecting belt 4, a transmission device 5, a support device 6, a guide slide 7, and a protective shell 8. The drying device 9, the air guiding box 10 and the support chassis 11, the upper end surface of the support chassis 11 is fixedly connected with the protective shell 8 for support, and the side end surface of the protective shell 8 is fixed An air guide box 10 for air guide is connected, and the inner end surfaces of the protective shell 8 and the support chassis 11 are uniformly equidistant and symmetrically fixedly connected with three sets of support devices 6 , and the inner end faces of the support devices 6 are rotated to Three groups of drying devices 9 are connected, and the center of the front end of the protective shell 8 is fixedly connected with a guide slide 7, and the upper side of the pr...

Embodiment 2

[0042] like Figure 1-3 As shown, as a further optimization scheme of the above embodiment: a raw material rapid drying device for log furniture production, including a toothed belt 1, a toothed pulley 2, a fixed gear 3, a connecting belt 4, a transmission device 5, and a supporting device 6. Guide slide 7, protective shell 8, drying device 9, air guide box 10 and support chassis 11, the upper end surface of the support chassis 11 is fixedly connected with protective shell 8 for support, and is located at the The side end surface of the protective shell 8 is fixedly connected with an air guide box 10 for guiding air, and the inner end surface of the protective shell 8 and the supporting chassis 11 is fixedly connected with three sets of support devices 6 evenly and equidistantly and symmetrically, and is located at the Three groups of drying devices 9 are connected to the inner end surface of the supporting device 6 by rotation, and the guide slide plate 7 is fixedly connected...

Embodiment 3

[0044] like Figure 1-4 As shown, as a further optimization scheme of the above embodiment: a raw material rapid drying device for log furniture production, including a toothed belt 1, a toothed pulley 2, a fixed gear 3, a connecting belt 4, a transmission device 5, and a supporting device 6. Guide slide 7, protective shell 8, drying device 9, air guide box 10 and support chassis 11, the upper end surface of the support chassis 11 is fixedly connected with protective shell 8 for support, and is located at the The side end surface of the protective shell 8 is fixedly connected with an air guide box 10 for guiding air, and the inner end surface of the protective shell 8 and the supporting chassis 11 is fixedly connected with three sets of support devices 6 evenly and equidistantly and symmetrically, and is located at the Three groups of drying devices 9 are connected to the inner end surface of the supporting device 6 by rotation, and the guide slide plate 7 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com