Base mechanical trigger fuze of rifle gun grenade

A fuze and artillery technology, applied in the field of mechanically triggering fuzes for rotating shells, can solve the problems of difficult to guarantee reliability, difficult to control cost, complex structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

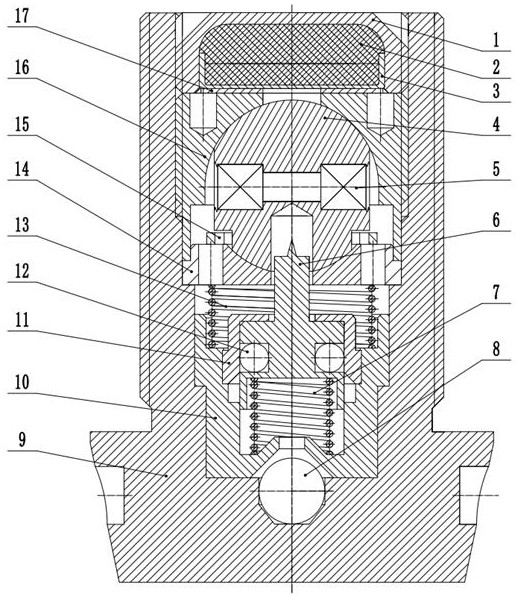

[0011] DRAWINGS The invention is described in further detail below in conjunction.

[0012] Combine figure 1 An artillery projectile projectile base rifled mechanical fuze, the fuze body lumen 9 in order from top to bottom comprises coaxially arranged detonators, safety and arming mechanism, the gasket 17, ballistic spring 13, ignition means, against 8 ball.

[0013] Wherein the squib comprises a downwardly opening housing a squib, transfer press fitted within a booster charge squib case 2, a booster shell 1 and closure 2 Booster reinforcing cap 3 pairs, with to strengthen the cap 3 with respect to the adjustment of the squib case a gap depth gasket 17. Booster selected black polyethylene -14 booster charge. That is, the end surface of the squib pass squib housing end surface 1, and the upper end surface 9 fuze toroidal body substantially flush. As an output terminal of the fuse, the top tube is a booster charge and the main projectile projectile is adjusted Emulsion paper mat. 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com