Motion control and diagnosis system for nuclear power in-service inspection automation device

An automation device and motion control technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve the problems that it is difficult for personnel to find abnormal motion functions at close range, and the cost of investigation is high, and achieves a light and small size. , Easy to operate, fast connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

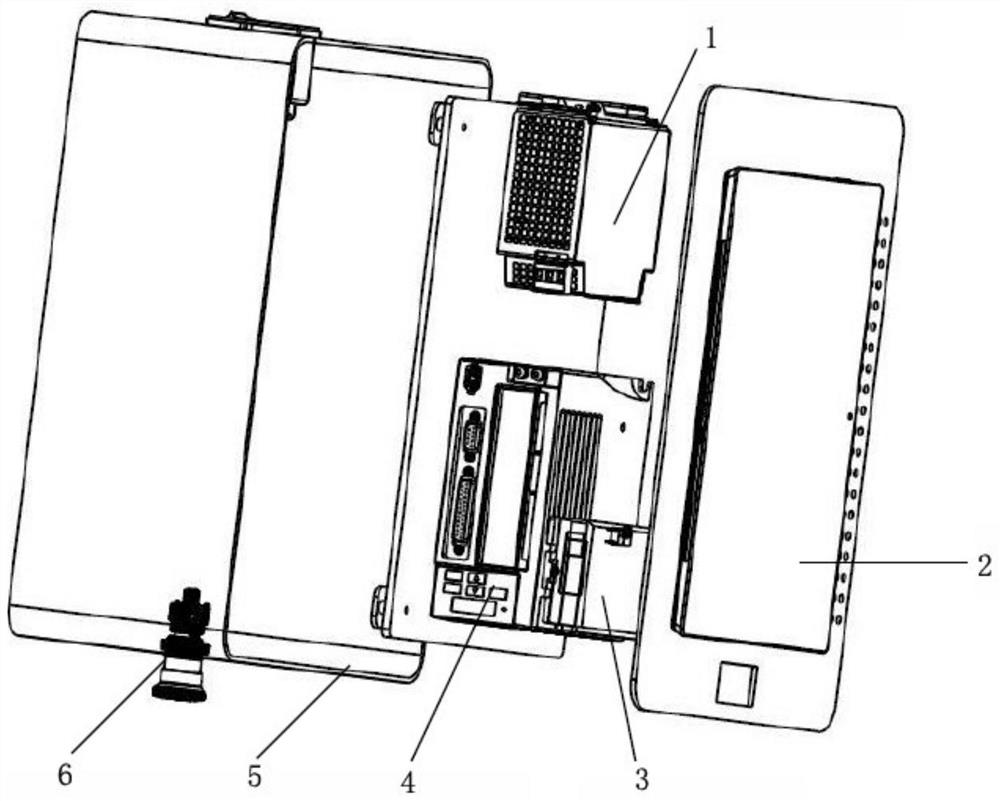

[0022] like figure 1 As shown, the motion control and diagnosis system for nuclear power in-service inspection automation devices includes an electric control unit, an emergency stop device, and cables connecting components of the electric control unit. The electric control box includes a box body 5, which is installed in the The motion controller 3, motor driver 4, emergency stop button 5, industrial computer 2, analog conversion module, encoder module, alarm module, power supply module 1 on the box body and the for The fan cooling module for cooling inside the electric control box.

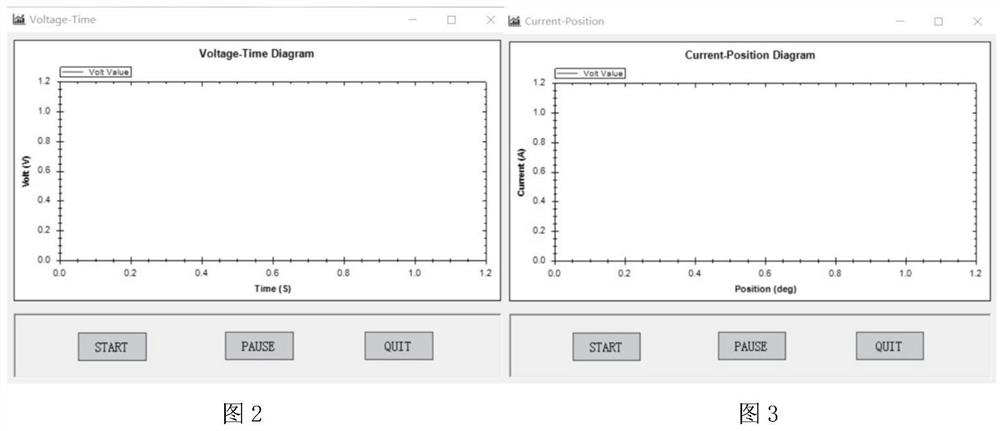

[0023] The encoder module is electrically connected to the motor driver, the motion controller accepts the motion command output by the industrial computer and sends an electrical signal to the motor driver to drive the motor, and at the same time reads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com