A method and system for real-time detection of welding defects based on high-frequency time-series data

A technology of time series data and welding defects, applied in image data processing, neural learning methods, image analysis, etc., can solve problems such as non-parallel calculation of cyclic neural network, slow training speed, long sequence length, etc., to achieve strong practical significance and speed up Training speed, real-time better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

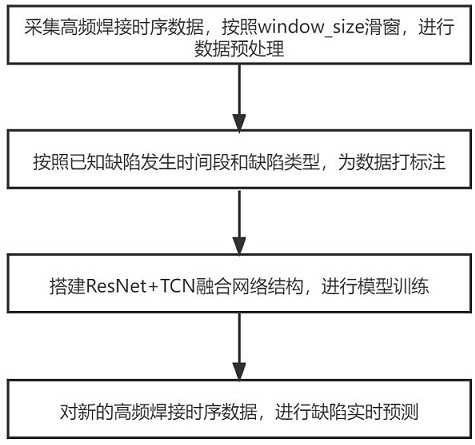

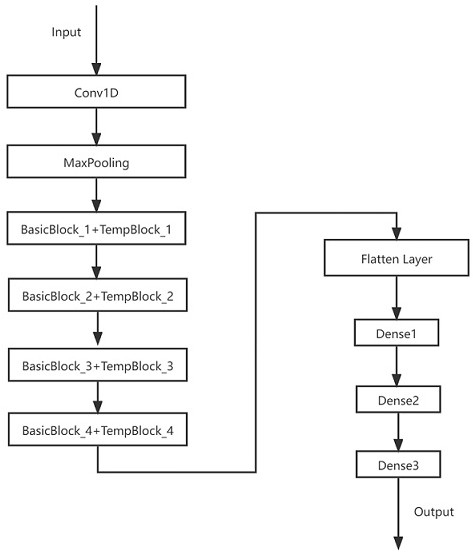

[0030] Such as figure 1 Shown is a real-time detection method for welding defects based on high-frequency time series data, including the following steps:

[0031] Step 1: Data preprocessing;

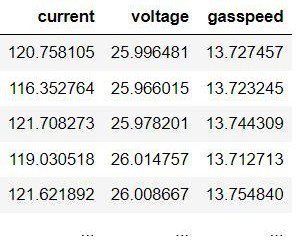

[0032] Step 1.1: Collect the high-frequency welding data (not lower than 10KHz, such as figure 2 As shown, the welding timing data in this embodiment includes current, voltage and airflow velocity), set the window length window_size=20000, each window length sequence is taken as a sample (a total of 1600 samples), and each sample is saved For a NumPy file, named data_i.npy;

[0033] Step 1.2: Label each sample according to the known defect occurrence time period and defect type, and save each label (label) as a NumPy file, named label_j.npy, i and j correspond one-to-one; where label There are three types:

[0034] label category 0 normal 1 Missing solder 2 Stomata

[0035] Step 1.3: Randomly shuffle all generated samples (out of order), set the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com