High-efficiency green production line and method for high-voltage cable

A high-voltage cable and production line technology, which is applied in the high-efficiency green production line of high-voltage cables, can solve the problems affecting the air environment of the cable production workshop and the appearance of high-efficiency cables, and achieve the effect of ensuring the cutting effect and environmental protection of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

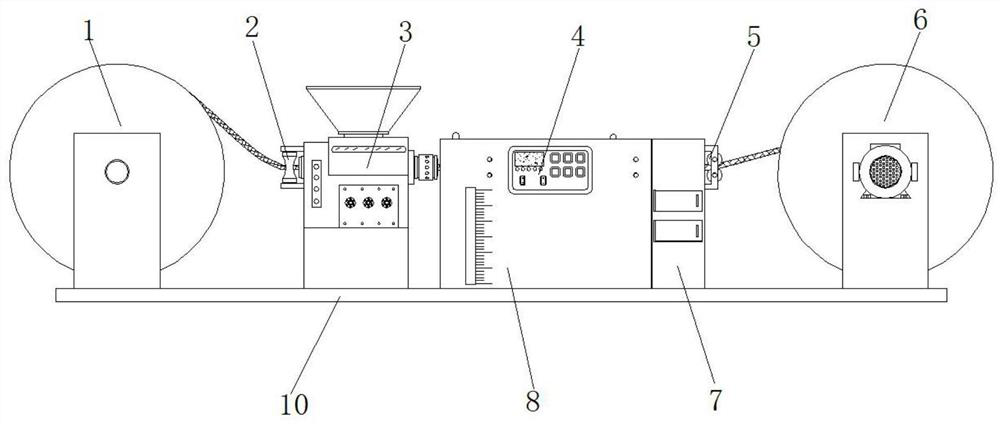

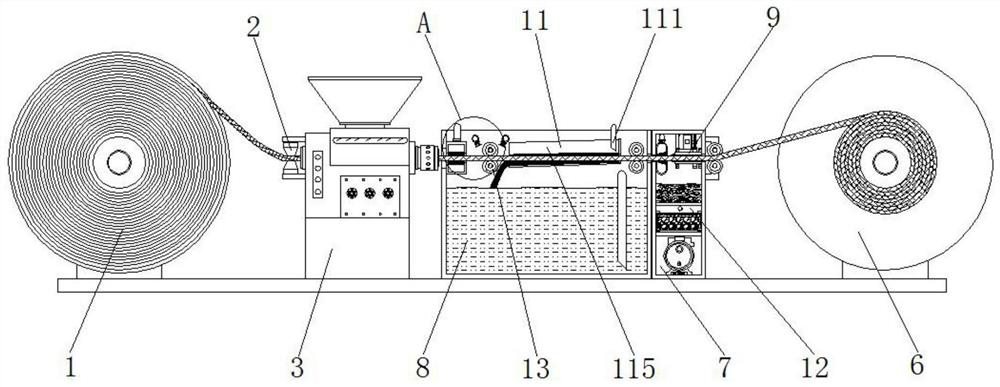

[0049] Example 1, such as figure 1 , 2 , 3, 4, 6, 7 and 8, the operator controls the winding machine 6 to start winding the core wire, after the core wire passes through the extruder 3, its surface is attached with a rubber jacket, and then the extruded When the high-voltage cable passes through the inner side of the second annular hollow chamber 21, the air pump 19 is controlled to start sucking air, forcing the cold air from the outside to carry the harmful gas emitted by the rubber jacket into the second annular hollow chamber 21, and the harmful gas passes through the intake pipe 14 and air pump 19 into the inside of the filter chamber 12, the harmful gas enters the inside of the first annular hollow chamber 16 through the air outlet pipe 15 after being filtered by the activated carbon 18, and is sprayed to the surface of the high-voltage cable by the first jet hole 17. The surface of the high-voltage cable coming out of the cooling water is cooled and dried by wind blowi...

Embodiment 2

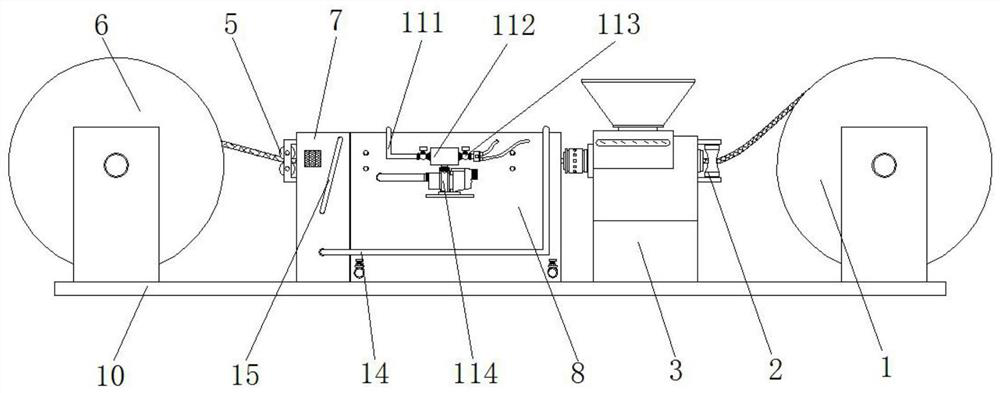

[0050] Example 2, such as figure 2 , 4 , 5 and 6, when the high-voltage cable passes through the ring cutter 901, the servo motor 902 is controlled to rotate, and the cooperation of the drive gear 903 and the rotation tube 904 drives the rotation tube 904 and the ring cutter 901 to rotate together, and the rotating ring cutter 901 removes the burrs existing on the outside of the high-voltage cable, and the air ejected from the first air jet hole 17 forces the removed burr to quickly separate from the high-voltage cable and fall into the cavity at the top of the filter chamber 12, after which the high-voltage cable passes through two sets of second Between the guide wheels 5, it is wound up by the winding machine 6, so as to realize the effect of deburring the surface of the high-voltage cable, and greatly ensure the aesthetics of the surface of the high-voltage cable after it is produced.

[0051]Working principle: Turn on the device before use, first install the cable reel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com