Non-excavation electric power pipe pulling construction hoop type pipeline connecting device in complex environment

A technology of complex environment and connection device, applied in the direction of electrical components, etc., can solve the problems of difficult connection between the drawn pipe section and the open cut section, slow construction progress, potential safety hazards, and influence on the sealing degree of the connection. The effect of firmness and improving the degree of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

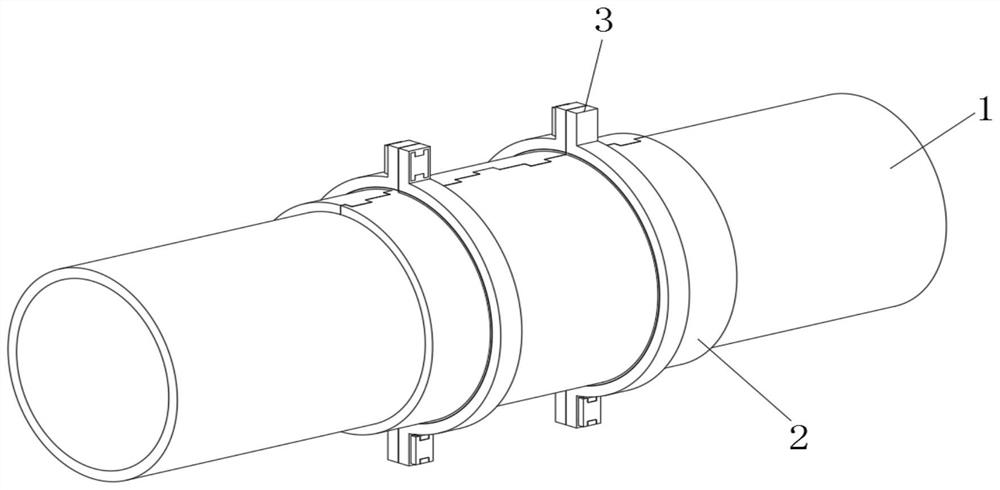

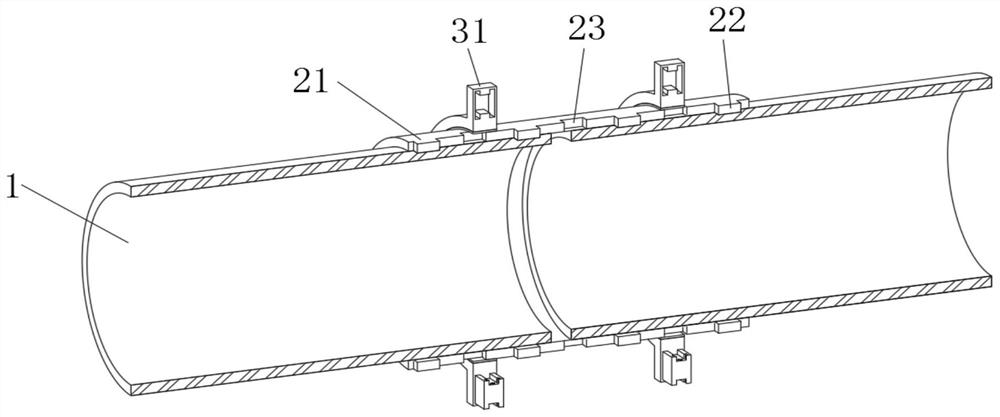

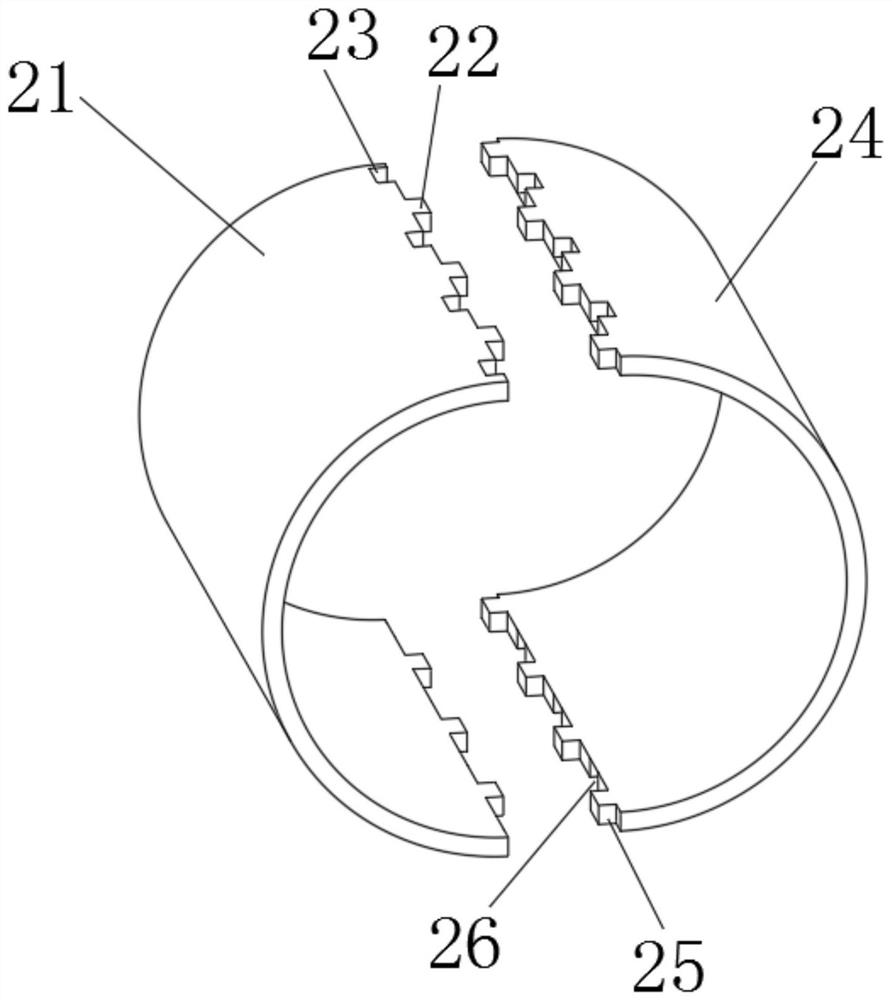

[0035] A hoop-type pipeline connection device for non-excavation electric pipe-drawing construction in complex environments, such as Figure 1-2 As shown, it includes an MPP power pipe 1 and a fastening mechanism 3 arranged outside the MPP power pipe 1. There are two MPP power pipes 1, and a connecting mechanism 2 is sleeved between the two MPP power pipes 1. The bending strength (Mpa) ≥ 37.0, tensile strength (Mpa) ≥ 24.0, two fastening mechanisms 3 are provided, and the two fastening mechanisms 3 are respectively detachable and installed on the left and right sides of the connecting mechanism 2, and the MPP power pipe 1 is modified High-strength polypropylene is the main raw material, which is suitable for medium and low voltage transmission line and cable pipes below 10kV. Its characteristics can meet the external pressure resistance required by the pipeline connectors (physical and mechanical properties: bending strength (23+2)C>37Mpa, Tensile strength (23+2)C>24Mpa), over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com