Solid waste recycling and crushing device

A technology of crushing device and crushing roller, which is used in solid separation, chemical instruments and methods, grain processing, etc. Improve the performance of use, the effect of rapid particle discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

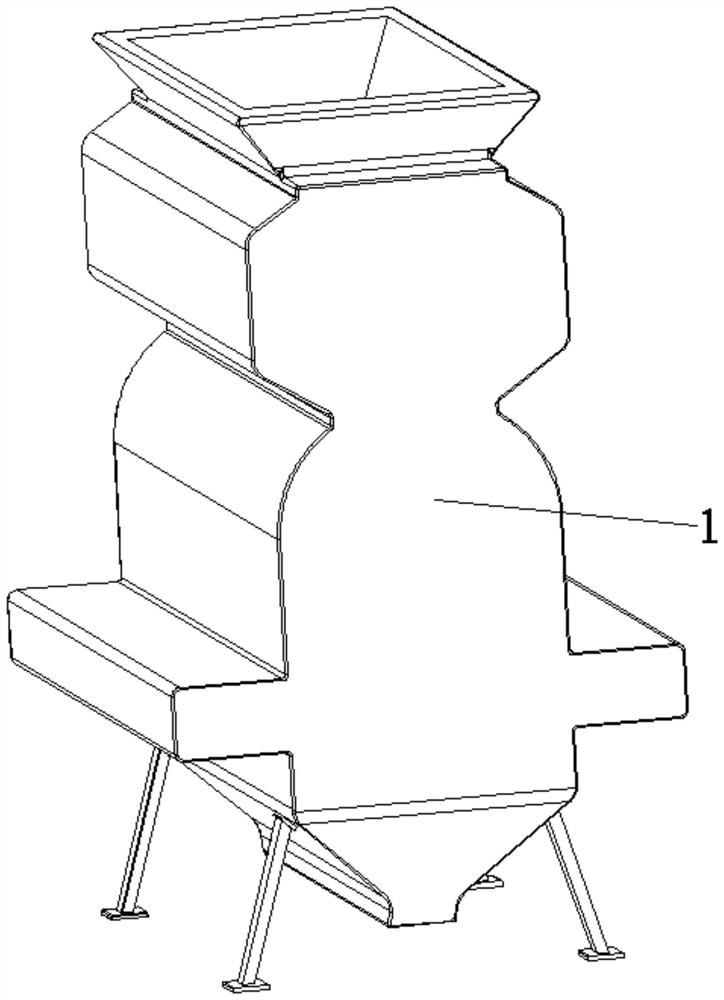

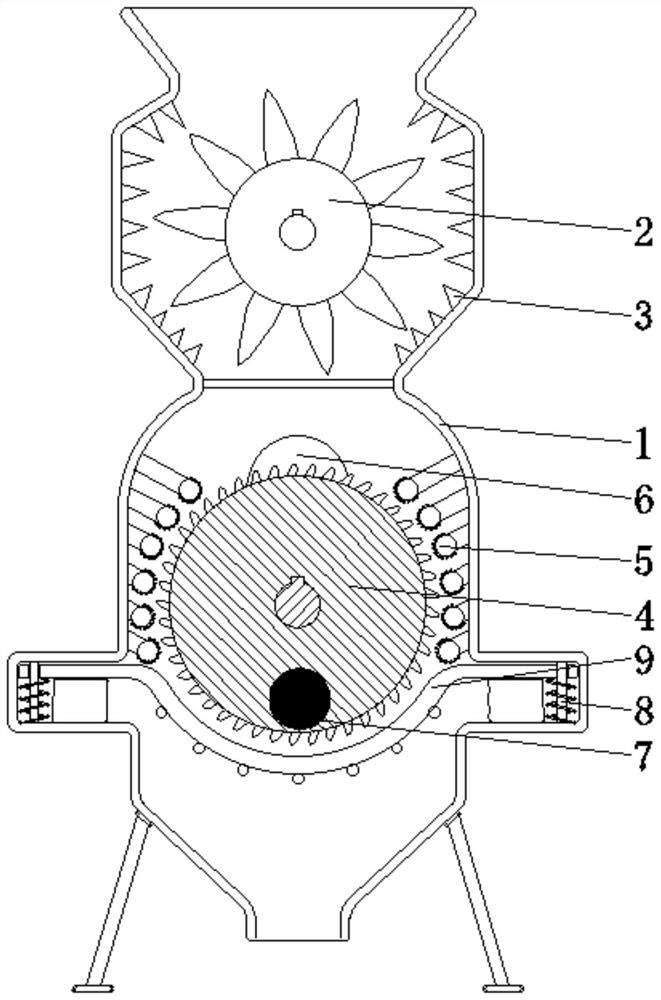

[0030] see Figure 1-7 , the present invention provides a technical solution: a solid waste recycling crushing device, including a shell 1, and the inside of the shell 1 is provided with a crushing roller 2, crushing teeth 3, abrasive rollers 4, grinding teeth 5, cams 6, and magnetic rods 7 , guide rod 8, sieve plate device 9, the crushing roller 2 is rotatably connected inside the casing 1 and close to the top position, the crushing teeth 3 are arranged on the inner wall of the casing 1 and located at the position of the crushing roller 2, and the abrasive roller 4 is rotatably connected to the casing 1 Inside and close to the bottom position, the grinding teeth 5 are arranged on the inner wall of the shell 1 and located at the position of the abrasive roller 4, the cam 6 is fixed on one end of the abrasive roller 4, the magnetic rod 7 is arranged inside the abrasive roller 4 and close to the position, and the sieve plate The device 9 is set on the inner wall of the housing 1...

Embodiment example 2

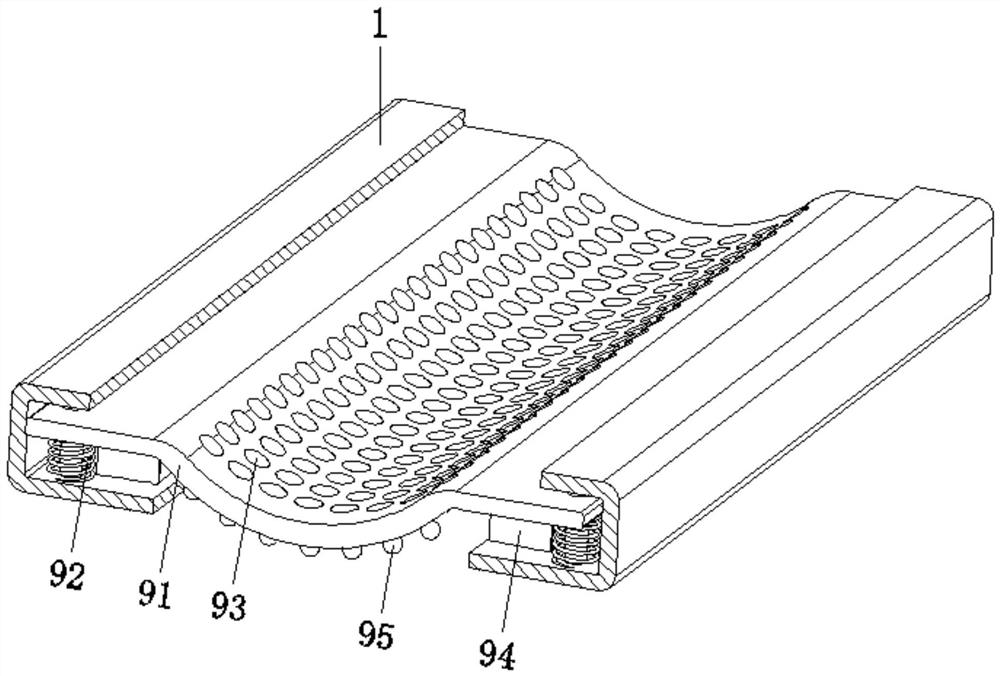

[0032] The sieve plate device 9 is provided with a sieve plate main body 91, a spring 92, a leakage hole 93, an air injection device 94, and a magnetic impact device 95. Between the corresponding two sides of the inner wall of the shell 1 and on the surface of the guide rod 8, the leakage hole 93 is opened on the surface of the sieve plate main body 91, the air injection device 94 is arranged at the bottom of the sieve plate main body 91, and the magnetic impact device 95 is arranged on the sieve plate main body 91. The bottom of the main body 91 and the position close to the leakage hole 93 are rotated by the abrasive roller 4, and the cam 6 and the magnetic bar 7 are rotated accordingly. After receiving the repelling magnetic force, the magnetic impact device 95 will impact the main body 91 of the sieve plate, thereby generating Vibration helps the dust to fall off automatically, and the rotating cam 6 will press the main body 91 of the sieve plate, so that the air injection ...

Embodiment example 3

[0034] The air injection device 94 is provided with a strip-shaped bag 941, a main air passage 942, and an arc-shaped conical hole 943. The strip-shaped bag 941 is arranged between the two sides corresponding to the bottom edge of the sieve plate main body 91 and the inner wall of the shell 1, and the main air passage 942 is opened. Inside the sieve plate main body 91, and the arc-shaped tapered hole 943 is inside the sieve plate main body 91 and is located at the position of the leakage hole 93. When the cam 6 rotates under the drive of the abrasive roller 4, the sieve plate main body 91 will be intermittently The strip-shaped bag 941 is compressed, and the interior is quickly discharged, and conveyed by the main air channel 942, and then ejected from the arc-shaped cone hole 943 to the leakage hole 93, which is helpful for the simultaneous removal of dust and solid waste particles. Blowing reduces the stickiness of dust and facilitates discharge, making it less prone to clogg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com