Silicon nitride composite ceramic lift tube for low-pressure casting and preparation method thereof

A composite ceramic and low pressure casting technology, which is applied in the field of silicon nitride composite ceramic liquid riser for low pressure casting and its preparation, can solve the problem of poor oxidation resistance and corrosion resistance of aluminum liquid, affecting thermal vibration resistance and air tightness, and production cost. And the problems of high maintenance cost, to achieve the effect of improving product cost performance, high strength and air tightness, and reducing adhesion and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

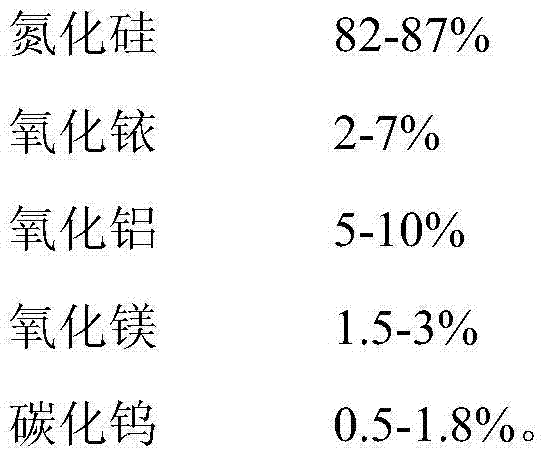

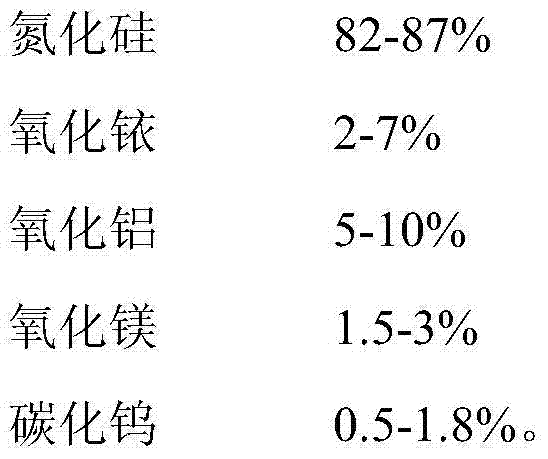

[0033] (1) Put 300 kg of silicon nitride, 12 kg of iridium oxide, 22 kg of aluminum oxide, 10 kg of magnesium oxide, 2 kg of tungsten carbide, 720 kg of silicon nitride grinding balls, and 280 kg of deionized water into the sand mill, Ball milled for 108 hours to obtain mixed homogeneous slurry, the slurry concentration was 55.3%, and the average particle size of the raw material particles in the slurry was 0.78 μm;

[0034] (2) Pour the slurry in step (1) into the mixing tank, add 8.5 kg of polyvinyl alcohol 1788, stir for 2 hours and then perform dry atomization treatment. The dry atomization temperature is 120°C, and the dry atomization time is 4 hours. A granulated raw material powder with an average particle size of 50 μm and a moisture content of 0.15% was obtained;

[0035] (3) The raw material powder for granulation in step (2) is processed by cold isostatic pressing equipment, the cold isostatic pressing pressure is 150MPa, and the holding time is 10 minutes, and the ...

Embodiment 2

[0040] (1) Put 300 kg of silicon nitride, 11 kg of iridium oxide, 24 kg of aluminum oxide, 9 kg of magnesium oxide, 3 kg of tungsten carbide, 750 kg of silicon nitride grinding balls, and 240 kg of deionized water into the sand mill, Ball milled for 115 hours to obtain mixed homogeneous slurry, the slurry concentration was 59%, and the average particle size of the raw material particles in the slurry was 0.75 μm;

[0041] (2) Pour the slurry in step (1) into the mixing tank, add 9 kg of polyvinyl alcohol 1799, stir for 2.5 hours and then perform dry atomization treatment. The dry atomization temperature is 160°C, and the dry atomization time is 4 hours. A granulated raw material powder with an average particle size of 150 μm and a moisture content of 0.25% was obtained;

[0042] (3) The raw material powder for granulation in step (2) is processed by cold isostatic pressing equipment, the pressure of cold isostatic pressing is 240 MPa, and the holding time is 15 minutes, and th...

Embodiment 3

[0047] (1) Put 300 kg of silicon nitride, 14 kg of iridium oxide, 26 kg of aluminum oxide, 8 kg of magnesium oxide, 4 kg of tungsten carbide, 800 kg of silicon nitride grinding balls, and 220 kg of deionized water into the sand mill, Ball milling for 120 hours to obtain mixed homogeneous slurry, the slurry concentration is 61%, and the average particle size of the raw material particles in the slurry is 0.6 μm;

[0048](2) Pour the slurry in step (1) into the mixing tank, add 9 kg of polyvinyl alcohol 1788, stir for 3 hours and then perform dry atomization treatment. The dry atomization temperature is 130°C, and the dry atomization time is 3 hours. A granulated raw material powder with an average particle size of 100 μm and a moisture content of 0.2% was obtained;

[0049] (3) The raw material powder for granulation in step (2) is processed by cold isostatic pressing equipment, the pressure of cold isostatic pressing is 200 MPa, and the holding time is 12 minutes, and the gree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com