Sand hanging separation blade type cooling pipe and molding method thereof

A technology of cooling pipe and sand block, which is applied in the field of metallurgical casting industry, can solve the problems of exacerbating the loosening of the cooling pipe, the damage of the sand core at the pipe mouth, the reverse movement of the cooling pipe, and the waste judgment of the water-cooled furnace mouth, so as to prevent the loosening of the cooling pipe and avoid Cooling pipe displacement, anti-high pressure gas impact displacement and loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

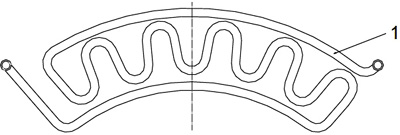

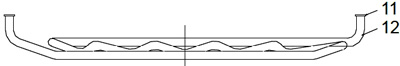

[0027] see figure 1 and figure 2 , The present invention provides a sand-hanging baffle-type cooling pipe, which is mainly composed of a cooling pipe 12, a sand-hanging baffle 11 and a water-cooled furnace mouth. The sand-hanging baffle 11 is made of ordinary steel with a thickness of 5-10 mm. The sand-hanging baffle 11 is centered and spot-welded to the head of the cooling pipe 12. The diameter of the sand-hanging baffle 11 should be larger than the outer diameter of the cooling pipe 12, generally greater than 10 mm. ~30 mm to form a sand-hanging baffle type cooling pipe 1, and the sand-hanging baffle type cooling pipe 1 is arranged in the furnace mouth cavity 6 made with molding sand.

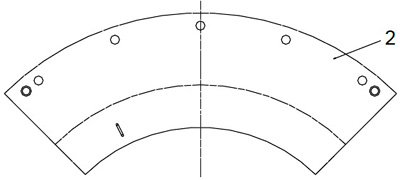

[0028] see image 3 and Figure 4 The hanging sand block 11 is buried and fixed inside the casting sand mold 2, the cooling pipe 12 is placed in the cavity 6 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com