Rotary support of micro turbojet engine

A technology of turbojet engine and rotating bracket, which is applied in the direction of jet power plant, motor vehicle, launching device, etc. It can solve the problems affecting the flight stability and safety hazards of unmanned aerial vehicles, achieve stable working performance, low manufacturing cost, The overall structure is concise and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

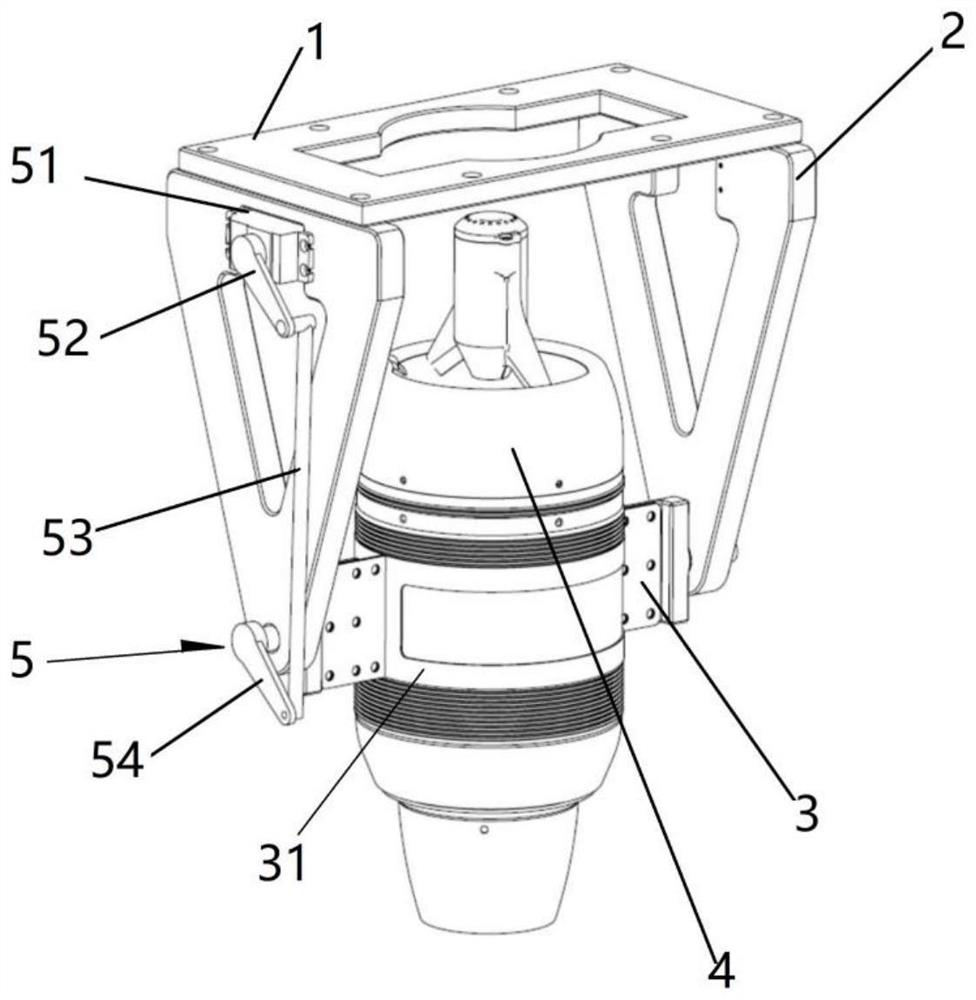

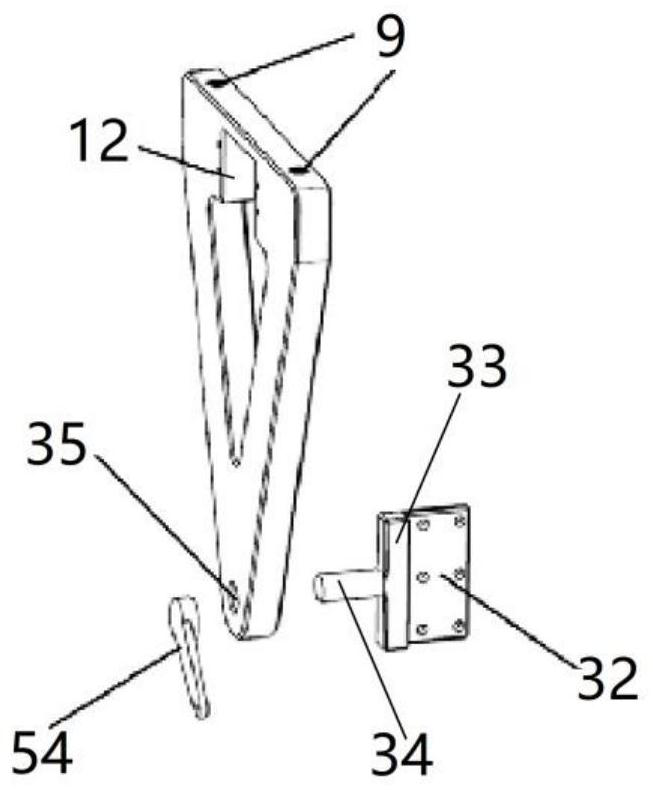

[0024] Embodiment 1: as figure 1 , figure 2 Shown, a kind of miniature turbojet engine rotating bracket comprises a pair of engine support side plates 2, and miniature turbojet engine 4 is rotatably installed between a pair of support side plates 2 by engine clamping rotating device 3; The connection cover plate 1 that connects carrying equipment is installed on a pair of supporting side plates 2 above the miniature turbojet engine 4 to ensure the overall structural strength; the carrying equipment mainly refers to unmanned aerial vehicles and unmanned aerial vehicles.

[0025] It also includes a rotary drive device 5, the rotary drive device 5 drives the miniature turbojet engine 4 to rotate through the engine clamping rotary device 3, thereby changing the injection angle of the micro turbojet engine 4 tail jet nozzle, the rotary drive device 5 is controlled by a wireless controller, The rotary drive device 5 sends a servo coded signal to the wireless controller to accurate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com