Cartridge receiver and fluid power equipment

A fluid power and equipment technology, applied in the field of casing and fluid power equipment, can solve the problems of the influence of the flow field structure, the axial and circumferential dimensions of the large perforation rate, and the efficiency loss, so as to reduce the blade load and solve the gap leakage flow. , the effect of expanding the stable operation margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

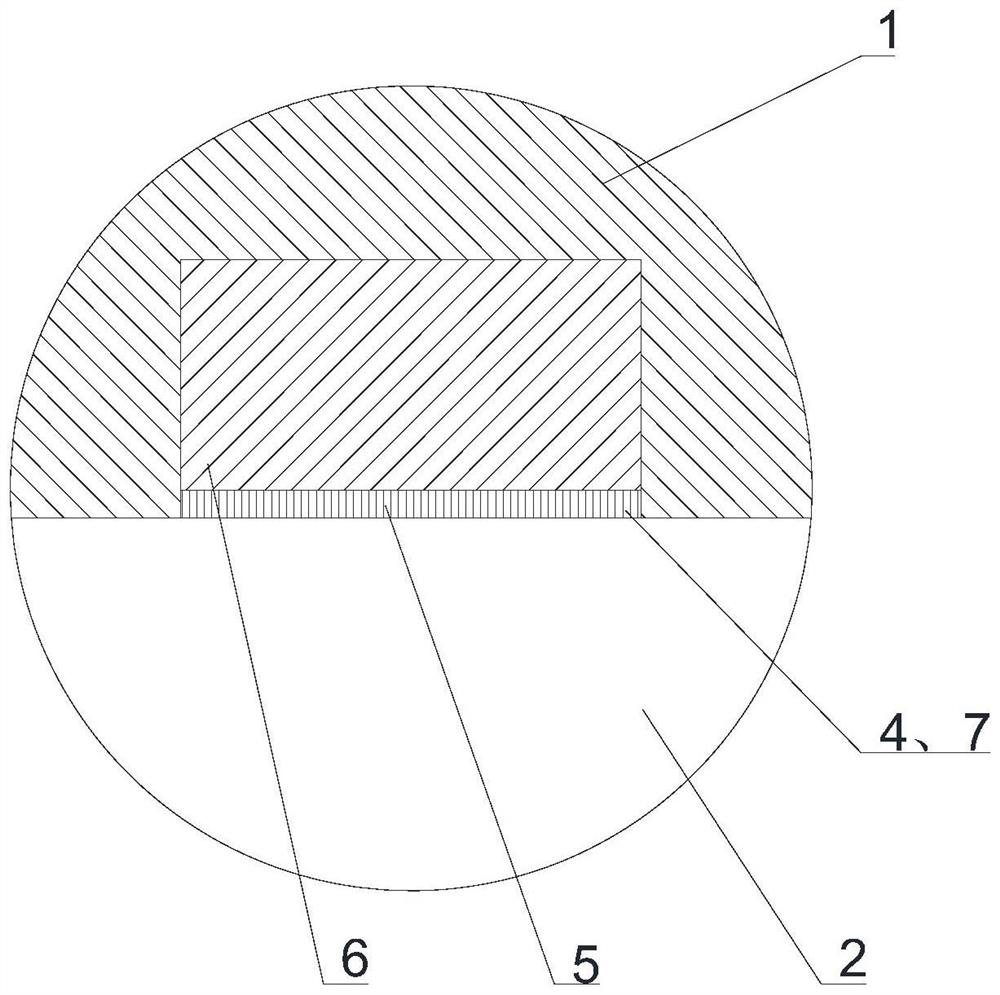

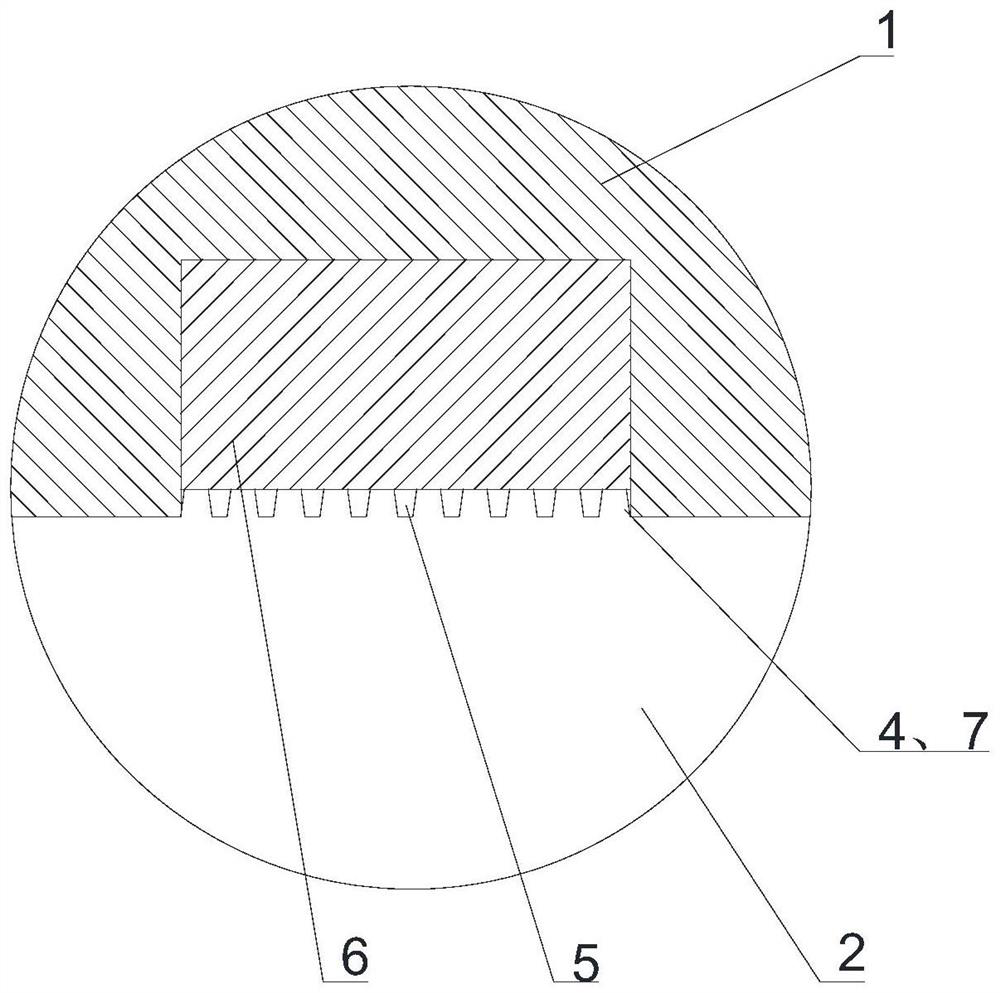

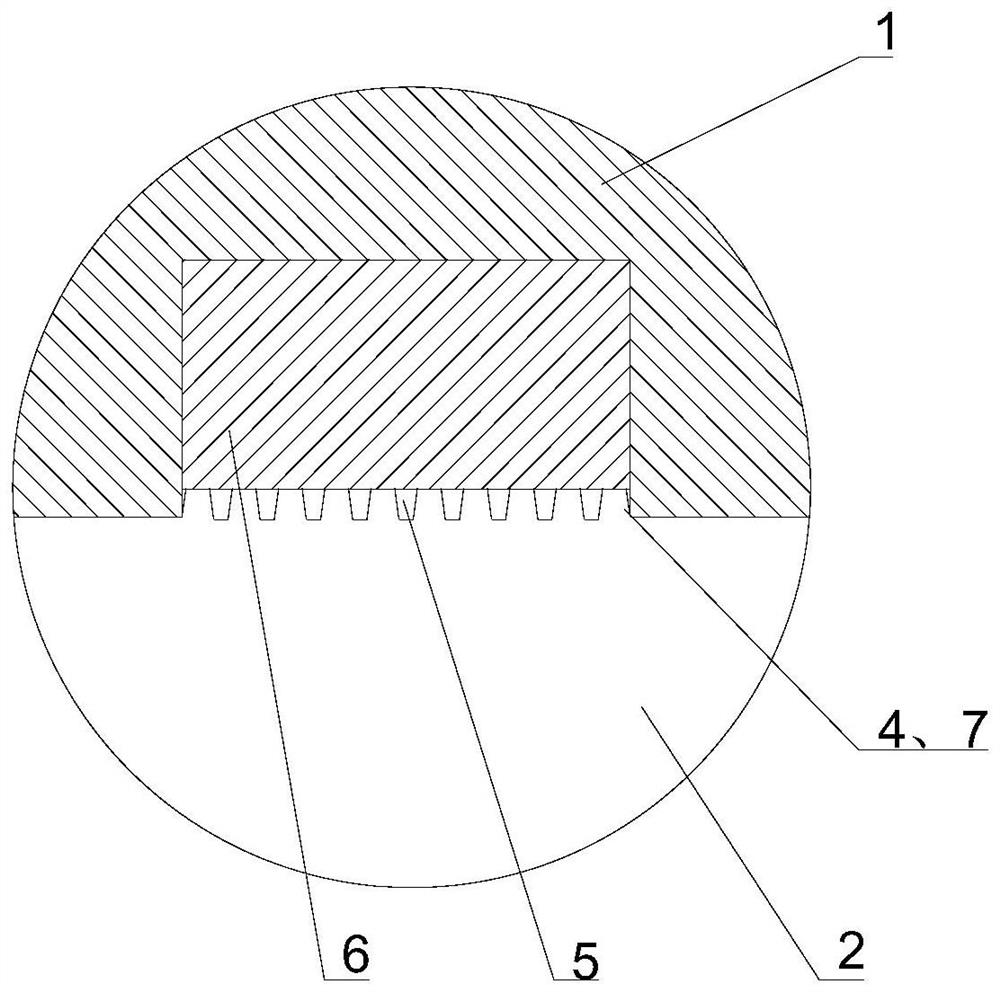

[0031] refer to Image 6 As shown, the embodiment of the present disclosure provides a fluid power device, the fluid power device may be a compressor, an engine, a water pump, an oil pump, etc.; For fluid, a rotatable impeller is installed in the fluid channel 2, and a circle of blades 3 is arranged on the impeller, and the rotation of the blades can drive the fluid from one end of the fluid channel 2 to the other end of the fluid channel;

[0032] However, there is an unavoidable leakage gap between the top of the blade 3 and the side wall of the fluid passage 2; when the fluid power device is working, a gap leakage flow from the pressure surface of the blade 3 to the suction surface will be formed in the gap: this gap Leakage flow will seriously affect the stable operation of fluid power equipment.

[0033] Based on this, an embodiment of the present disclosure provides a casing to break up the gap leakage flow and reduce the impact of the gap leakage flow on the stability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com