Wear-resistant shaft seal type rotary sealing device and machining process

A technology of rotary sealing and shaft sealing, which is applied in the direction of engine sealing, shaft, shaft and bearing, etc. It can solve problems such as surface scratches and rotary joint leakage, and achieve the effects of prolonging service life, preventing dry friction, and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now described in detail with accompanying drawings as follows. The embodiments described in the accompanying drawings are only used to illustrate the technical solutions of the present invention and are not limiting this invention.

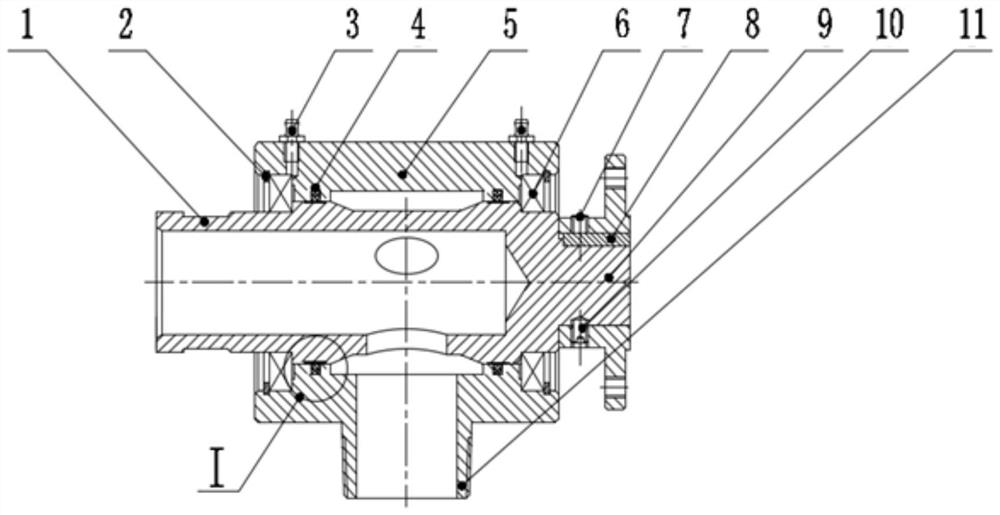

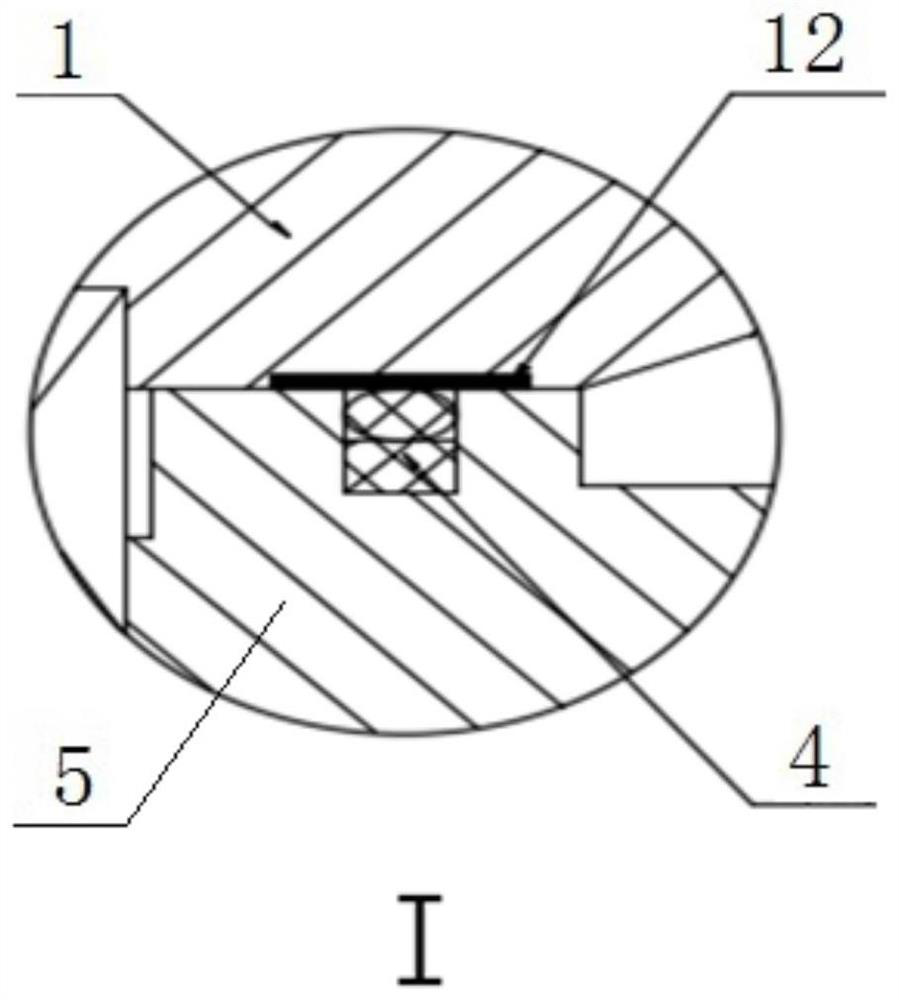

[0015] Such as figure 1 with figure 2 As shown, a rotary sealing device in the form of a wear-resistant shaft seal includes a rotating shaft 1; wherein, the rotating shaft 1 is provided with a casing 5, and at two annular sealing surfaces where the casing 5 contacts the rotating shaft 1, the casing One side of shaft 5 is provided with rotating gray ring 4, and one side of shaft 1 is provided with ceramic Cr 2 0 3 layer 12; the outer sides of the two annular sealing surfaces are provided with bearings 6, which support and fix the rotating shaft 1 front and rear, and the outer sides of the bearings 6 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com