Breathing cap for main feed pump of nuclear power plant

A main feed water pump, nuclear power plant technology, applied to the components of the pumping device for elastic fluid, pump elements, variable capacity pump components, etc., can solve problems such as fire hazards, polluted equipment, and poor breathing. Achieve the effect of guaranteeing smooth discharge, good use effect and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

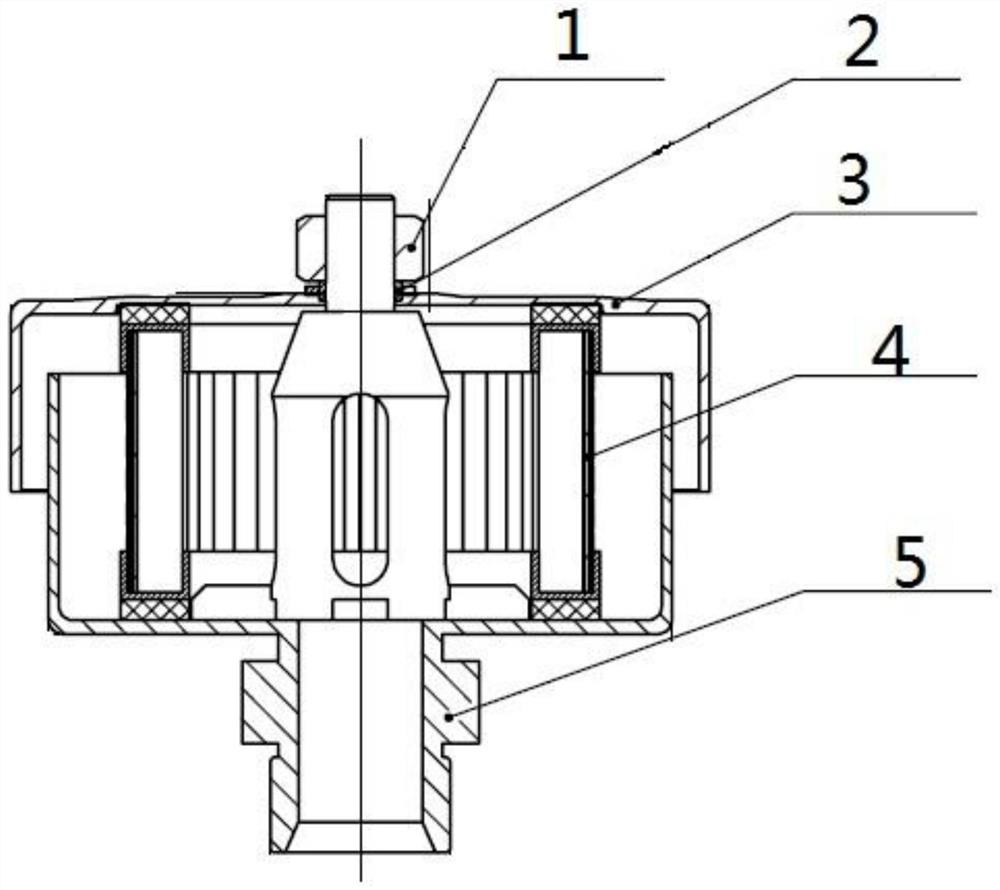

[0015] like figure 1 As shown, a breathing cap used for the main feedwater pump of a nuclear power plant includes a locknut 1, a rubber gasket 2, a breathing cap upper cover 3, a filter element 4 and a breathing cap base 5, wherein,

[0016] The breathing cap upper cover 3 is set on the breathing cap base 5 , the breathing cap upper cover 3 and the breathing cap base 5 are cylindrical structures with one end open, and the breathing cap base 5 is provided with a filter element 4 .

[0017] The upper part of the breathing cap is fastened with a rubber washer 2 and a locknut 1, which not only prevents oil leakage but also prevents the upper cover from loosening.

[0018] The overall shell of the breathing cap is made of stainless steel, with a beautiful appearance, and it is only necessary to check and clean the equipment during mainten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com