Electric power production waste gas emission detection system based on 5G communication

An exhaust emission and detection system technology, applied in signal transmission systems, pipeline systems, multi-way valves, etc., can solve the problems of inability to intuitively understand the detection data in real time and the high cost of design solutions, so as to reduce detection costs, collect timely, and save investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

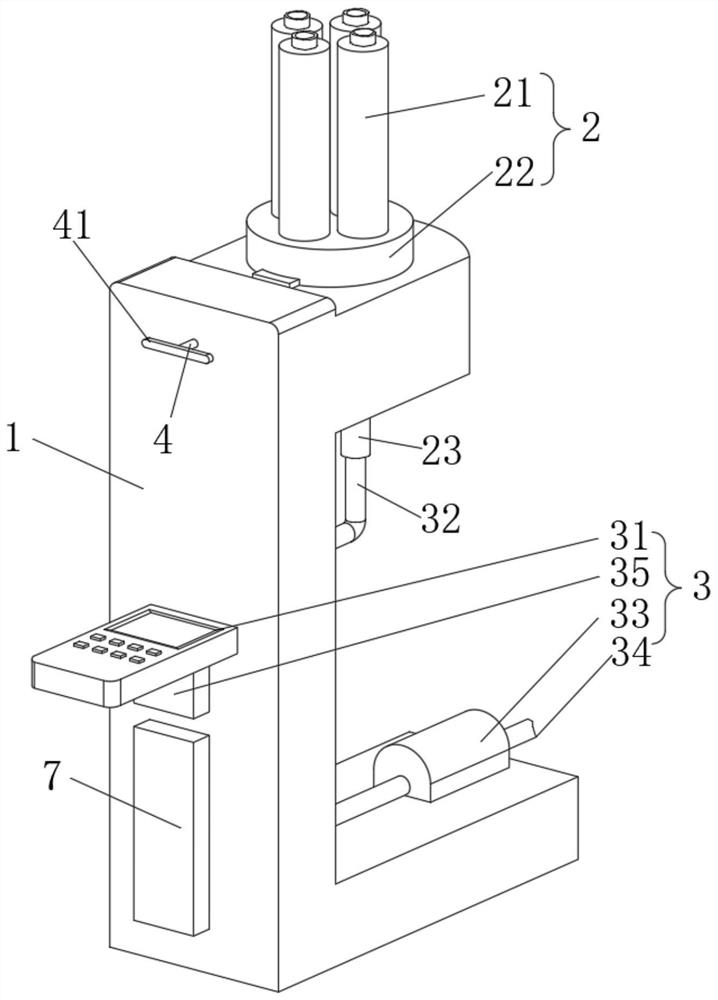

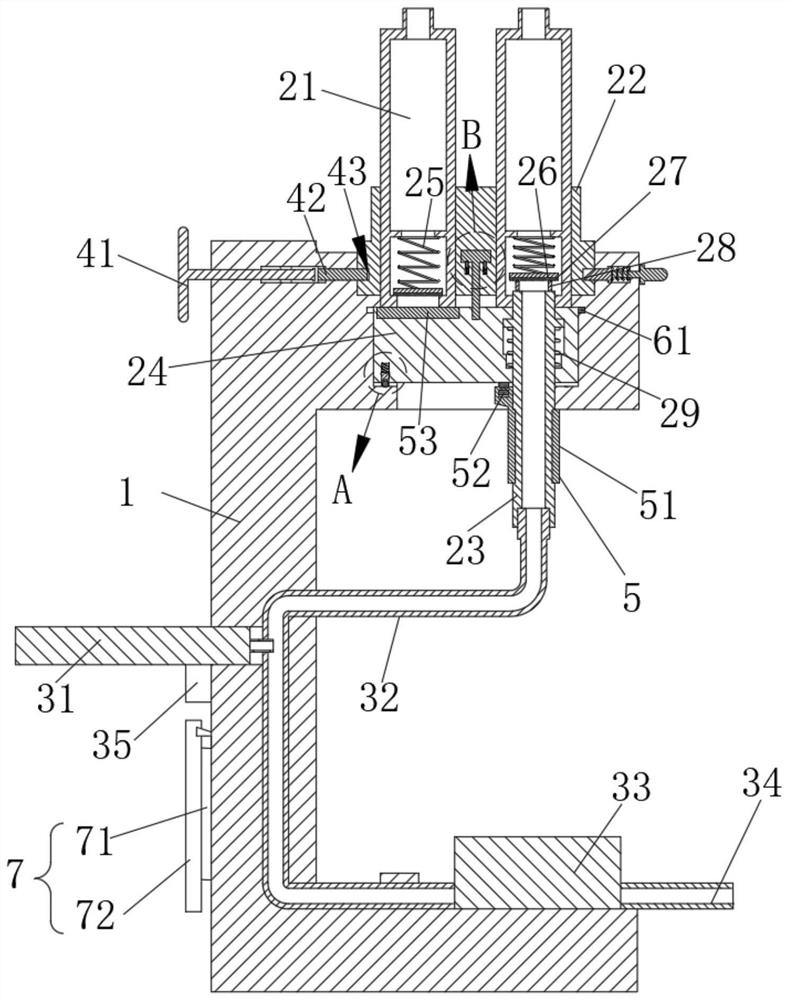

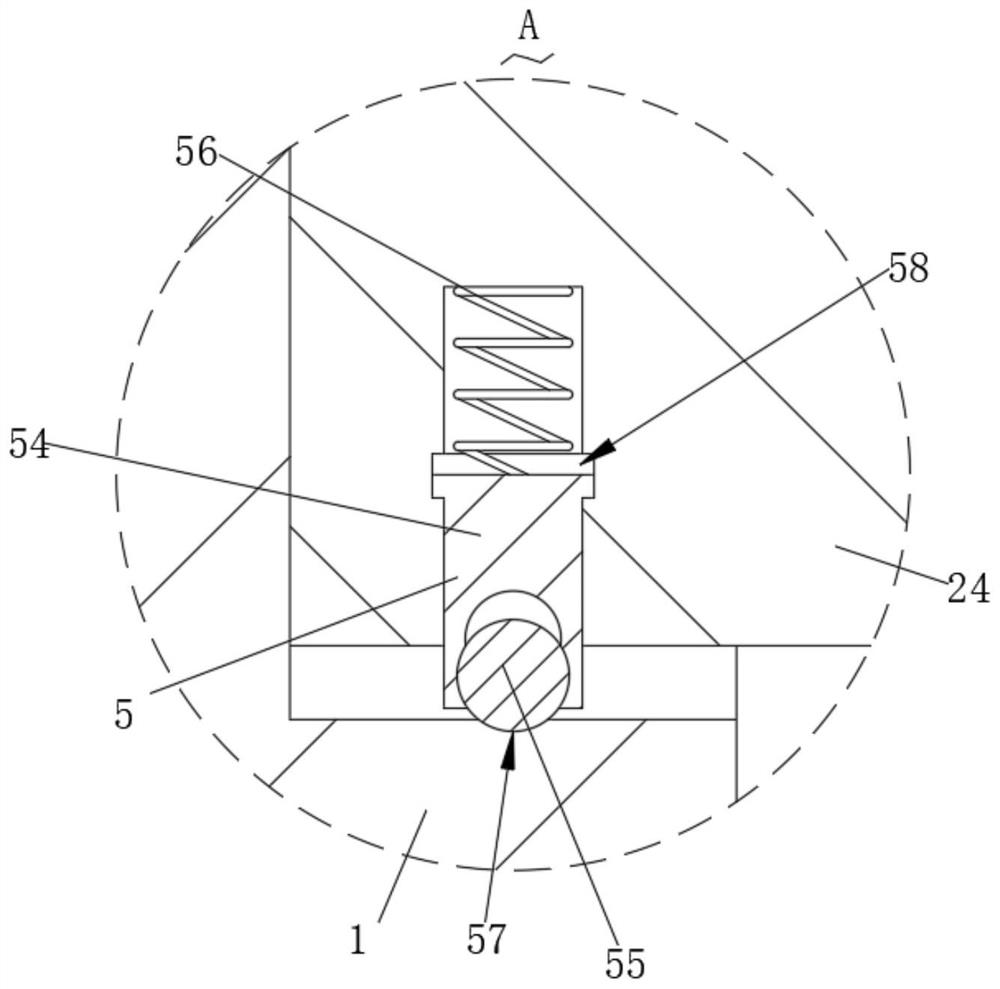

[0034] Refer to the attached Figure 1-7 A 5G communication-based power generation exhaust emission detection system according to an embodiment of the present invention is described.

[0035] The 5G communication-based power production waste gas emission detection system according to the present invention includes: power plant gas detection base 1, power plant waste gas conversion structure 2, power plant waste gas detection wireless communication structure 3, waste gas conversion installation structure 4, waste gas sealing structure 5 and wireless charging Component7.

[0036] Among them, the gas detection base 1 of the power plant has a mounting hole, and the waste gas conversion structure 2 of the power plant is arranged at the mounting hole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com