Method for judging whether moisture of baked lithium ion batteries is qualified or not

A technology for lithium-ion batteries after baking, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries. Signal amplification is obvious, avoiding the effect of long period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for judging the moisture content of lithium-ion batteries after baking, comprising the steps of:

[0026] (1) Select 2,000 lithium-ion batteries with qualified water content as standard batteries, and establish 2,000 corresponding lithium-ion batteries to standardize into a dQ / dV-V curve, where Q is the charging capacity and V is the voltage;

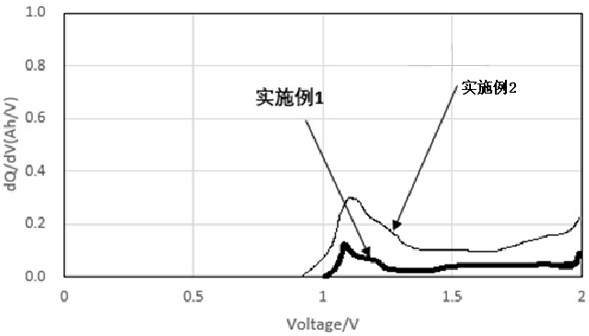

[0027] (2) Extract the dQ / dV value in the range of 0.8-1.5V from the above normalized dQ / dV-V curve, get 2000 peak values of dQ / dV in the range of 0.8-1.5V, select the largest peak value as the standard peak value, the standard The peak value is 0.2 Ah / V;

[0028] (3) Select a baked lithium-ion battery as the battery to be tested, and establish the actual dQ / dV-V curve of the lithium-ion battery, as shown in figure 1 shown;

[0029] (4) According to the standard peak value and the dQ / dV peak value of the battery under test in the 0.8-1.5V range, judge whether the water content of the battery to be tested is qualified...

Embodiment 2

[0033] A method for judging the moisture content of lithium-ion batteries after baking, comprising the steps of:

[0034] (1) Select 2,000 lithium-ion batteries with qualified water content as standard batteries, and establish 2,000 corresponding lithium-ion batteries to standardize into a dQ / dV-V curve, where Q is the charge and discharge capacity, and V is the voltage;

[0035] (2) Extract the dQ / dV value in the range of 0.8-1.5V from the above-mentioned standardized dQ / dV-V curve, and obtain 1000 peak values of dQ / dV in the range of 0.8-1.5V, and select the largest peak value as the standard peak value. The peak value is 0.2 Ah / V;

[0036] (3) Select a baked lithium-ion battery as the battery to be tested, and establish the actual dQ / dV-V curve of the lithium-ion battery, as shown in figure 1 shown;

[0037](4) According to the standard peak value and the dQ / dV peak value of the battery under test in the 0.8-1.5V range, judge whether the water content of the battery to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com