Mesogen polarizer

一种液晶基元、液晶的技术,应用在光学元件、光学元件、眼镜/防护镜等方向,能够解决性能限制等效透射损失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] Preparation of Liquid Crystal Cell Polarizers

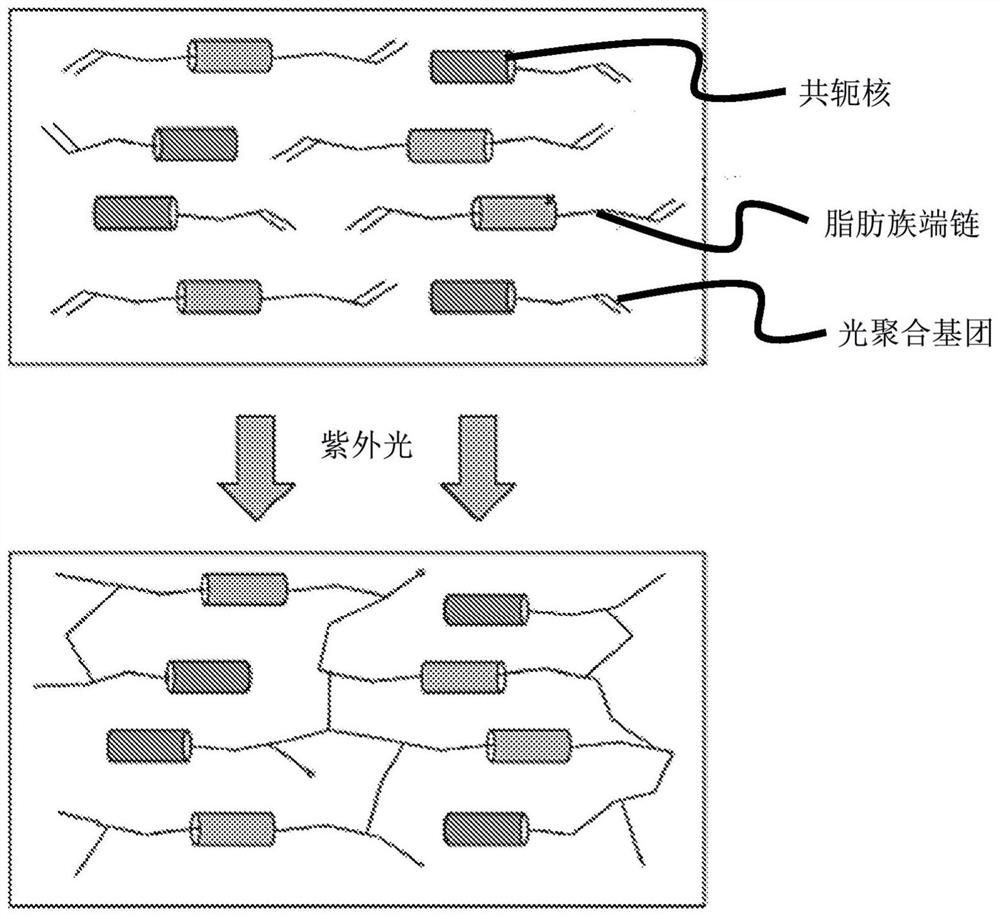

[0064] refer to Figure 5 , an exemplary method of preparing a mesogen polarizing plate is described below. These methods employ EMD / Merck mesogens. It should be understood that different reactive mesogens may require different preparation methods. The following is provided for purposes of illustration and not limitation.

[0065] A. Preparation of controlled retardation layer

[0066] The various controlled retardation layers tested included biaxially oriented polypropylene (BOPP), such as TX-G available from Toray; polycarbonate, such as Teijin's Panlite PC-1151, and LOFO's cycloolefin Copolymer (COC).

[0067] In order for a controlled retardation layer to act as a retardation layer, it needs to have a retardation in the range of 50-260nm, with a target of 147nm (measured at 590nm). It is also desirable to have engineered retardation across the entire visible spectrum, nominally 380-780nm. This retardation design...

Embodiment 1

[0092] Display delay fine-tuning: (JL0172-3).

[0093] Support layer - flat molded polycarbonate lens thickness between 0.25 and 3mm.

[0094] Optionally, sputter coating is used to coat the silicon dioxide surface layer with a thickness between 20 and 400 nm.

[0095] Spin coat 0.5ml Licrivue RMS09-032.

[0096] Anneal at 85 °C for 1 min.

[0097] UV cure at 25mw / sq cm for 1 minute under nitrogen atmosphere.

[0098] A controlled retardation layer was applied to the mesogen surface with a 37 micron thick optical polyurethane adhesive (eg, as described in US Patent Application Serial No. 16 / 101,368, incorporated herein by reference).

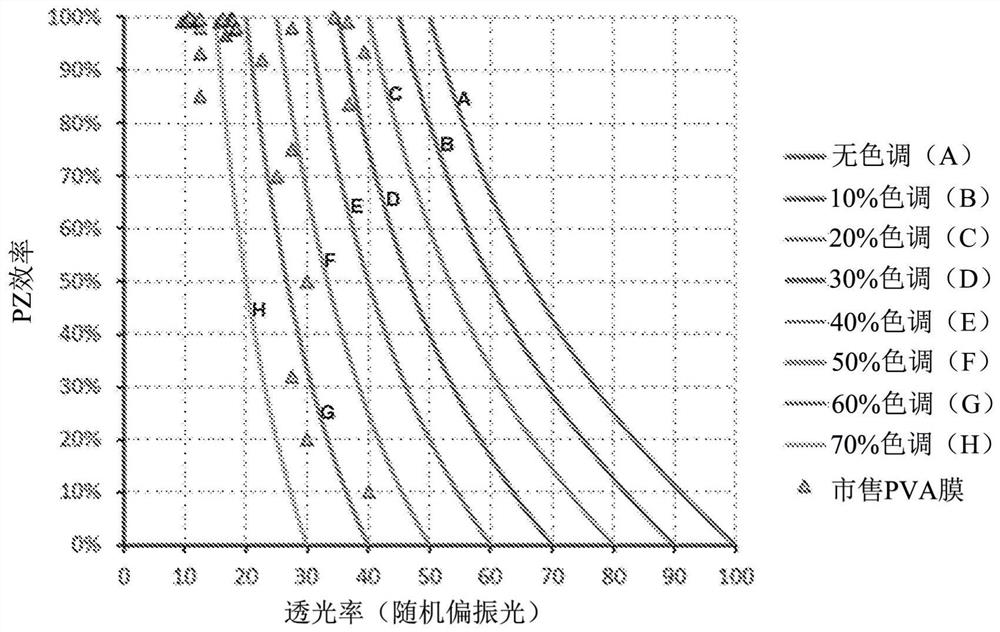

[0099] Spectra were measured with a Perkin Elmer PE-1050 spectrometer. The various curves in the graph represent different polarization angles of light reaching the mesogen sample under test, relative to the orientation direction of the mesogen. The incident light passes through a polarizing filter (Glan-Taylor polarizing crystal provided b...

Embodiment 2

[0102] The retardation of the polycarbonate sheet was adjusted by stretching under tension at 145°C.

[0103] Support layer - flat molded polycarbonate lens thickness between 0.25 and 3mm.

[0104] Table 1 Comparison of retardation and polarization efficiency of laminated films

[0105]

[0106]

[0107] While not wishing to be bound by theory, it is hypothesized that the retardation film converts linearly polarized light to circularly polarized light, optimally around a 147nm retardation. Depending on the angle of the retardation layer relative to the polarization state of the incident light, circularly polarized light is either reflected by the mesogen or passes through the mesogen. Control of reflected (ie, polarized) glare is achieved by orienting the retardation direction of the film relative to the polarization state of the light associated with the glare.

[0108] In the remaining examples, we present samples consisting of mesogens coated on controlled retardati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com