Automatic mechanical device for integrating sowing and irrigation of crops

A mechanical device and crop technology, which is applied in the direction of sowing seeders, planter parts, watering devices, etc., can solve the problems of increasing manpower, material resource consumption, increasing production time, affecting germination rate, etc., to reduce manpower and production time , the effect of reducing water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

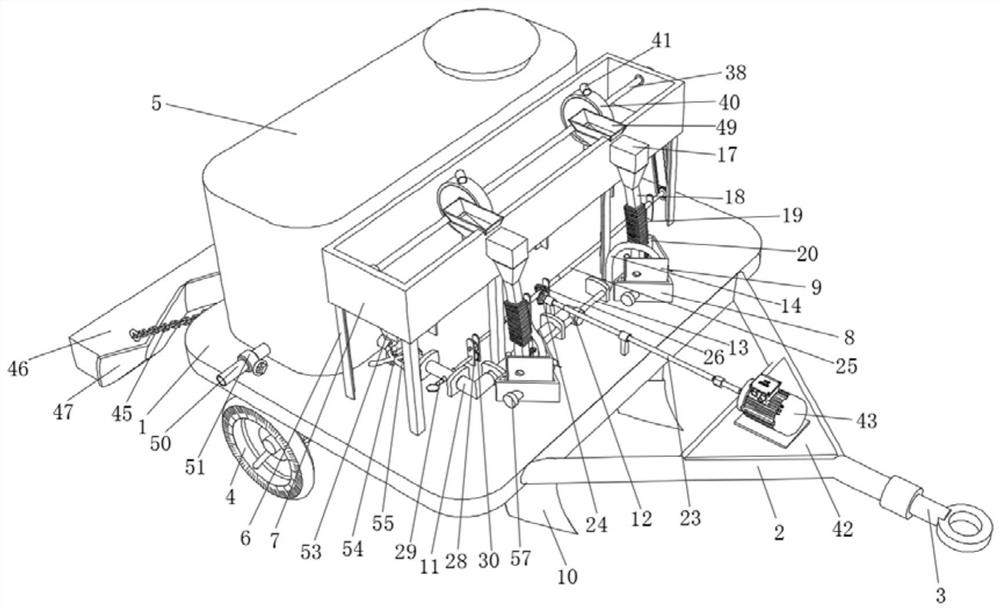

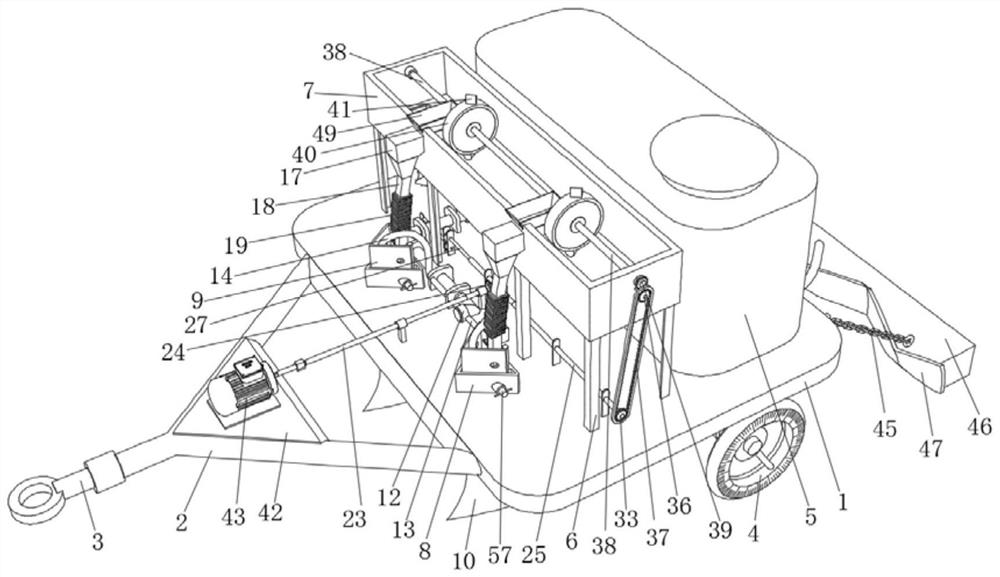

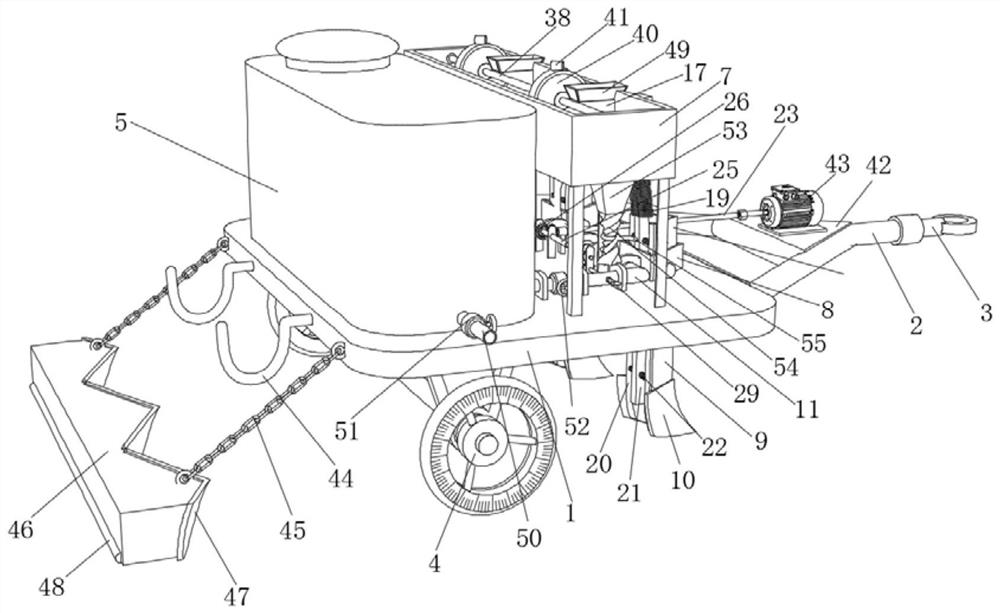

[0037] refer to Figure 1-10 , an automatic mechanical device for crop sowing and irrigation, comprising a platform 1, a connecting frame 2 is fixedly connected to one side of the platform 1, the other end of the connecting frame 2 is provided with a traction sleeve 3, and the bottom of the platform 1 is provided with wheels 4. The top of the platform 1 is fixedly connected with a water tank 5 and a plurality of supporting feet 6, the top of the plurality of supporting feet 6 is fixedly connected with the same seed box 7, and the top of the platform 1 is fixedly penetrated with two limit tubes 8 arranged symmetrically to limit the The inside of the position tube 8 is fixedly connected with a V-shaped plate 9 through a limit adjustment mechanism, and the same coulter 10 is fixedly connected to both sides of the V-shaped plate 9 close to the traction sleeve 3, and the coulter 10 is located below the platform 1, and the water tank 5 One side of the water outlet pipe 11 is fixedly...

Embodiment 2

[0039] refer to Figure 1-10 , the present invention provides a technical solution: an automatic mechanical device for crop sowing and irrigation, comprising a platform 1, a connecting frame 2 is fixedly connected to one side of the platform 1, and the other end of the connecting frame 2 is provided with a traction sleeve 3 , the bottom of the platform 1 is provided with wheels 4, the top of the platform 1 is fixedly connected with a water tank 5 and a plurality of feet 6, the top of the plurality of feet 6 is fixedly connected with the same seed box 7, and the bottom of the seed box 7 is fixedly connected with a recovery conduit 53, the bottom of the recovery conduit 53 is fixedly connected with a first distribution pipe 54, the outer wall of the first distribution pipe 54 is provided with a binding rope 55, and the top of the platform 1 is fixedly penetrated with two symmetrically arranged limit pipes 8, the limit pipes 8 A V-shaped plate 9 is fixedly connected to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com