Curing method suitable for curing K326 tobacco leaves in movable curing barn and obtained tobacco leaves

A curing method and technology of tobacco leaves, which are applied in the fields of tobacco, application, and preparation of tobacco, can solve the problems of low content of medium and high tobacco, high content of low-grade tobacco, and easy ash on tobacco leaves, so as to promote the transformation of tobacco leaves and reduce energy consumption. Reduce and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

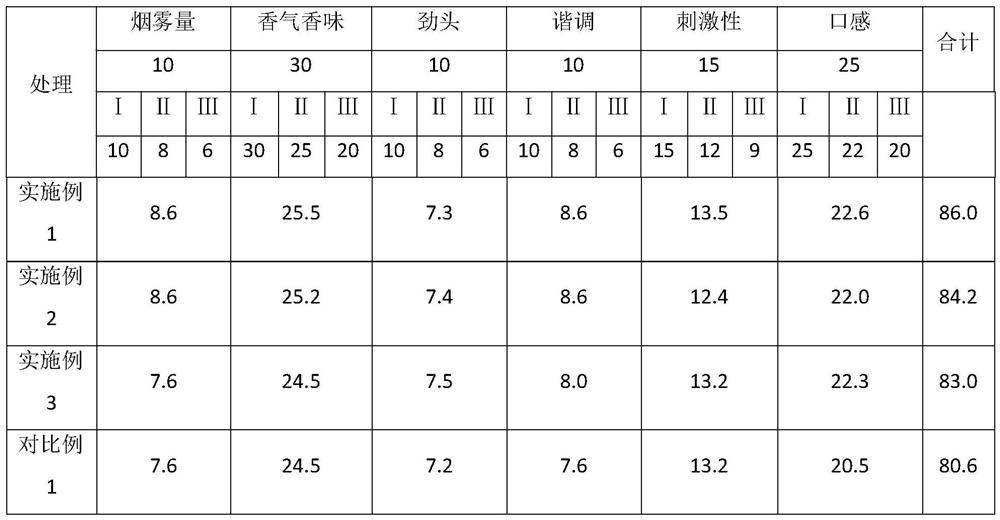

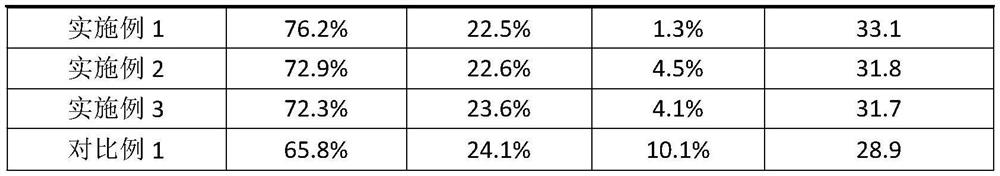

Examples

Embodiment 1

[0032] This embodiment relates to a method suitable for roasting K326 tobacco leaves in a mobile barn. The mobile barn belongs to the air flow descending barn. The size of the tobacco room in the barn is 6000mm long, 2700mm wide, and 3500mm high, and it is divided into three layers. Smoked, middle layer, top layer and bottom layer. The method includes the following steps:

[0033] S100: Harvest K326 ripe fresh tobacco leaves planted in Yangbi County, Dali Prefecture for this experiment according to the requirement that the tendons turn white, the leaf surface is light yellow and most of the down hairs fall off.

[0034] S200: Weave the harvested fresh tobacco leaves according to the conventional method. The upper part is denser and the lower part is thinner. Gradually reduce 1-2 rods of tobacco to meet the requirements of dislocation and crossing. Put them into the mobile curing barn. It is recommended to load 260 rods of tobacco and wait for curing.

[0035] S300: The yellowin...

Embodiment 2

[0039] A roasting method suitable for roasting K326 tobacco leaves in a mobile barn. The mobile barn belongs to the air-flow descending barn. The size of the tobacco room in the barn is 6000mm long, 2700mm wide, and 3500mm high. The tobacco is divided into three layers. layer, top layer, and bottom layer. The method includes the following steps:

[0040] S100: Harvest K326 ripe fresh tobacco leaves planted in Yangbi County, Dali Prefecture for this experiment according to the requirement that the tendons turn white, the leaf surface is light yellow and most of the down hairs fall off.

[0041] S200: The harvested fresh tobacco leaves are weaved according to the conventional stalks, dense at the top and thin at the bottom, and gradually reduce 1 to 2 stalks of tobacco to form a dislocation and intersection requirement, and put them into the mobile curing barn. The recommended amount of tobacco is 270 stalks, waiting to be roasted.

[0042] S300: The yellowing period includes t...

Embodiment 3

[0046] A roasting method suitable for roasting K326 tobacco leaves in a mobile barn. The mobile barn belongs to the air-flow descending barn. The size of the tobacco room in the barn is 6000mm long, 2700mm wide, and 3500mm high. The tobacco is divided into three layers. layer, top layer, and bottom layer. The method includes the following steps:

[0047] S100: Harvest K326 ripe fresh tobacco leaves planted in Yangbi County, Dali Prefecture for this experiment according to the requirement that the tendons turn white, the leaf surface is light yellow and most of the down hairs fall off.

[0048] S200: Weave the harvested fresh tobacco leaves according to the conventional method. The upper part is denser and the lower part is thinner. Gradually reduce 1-2 rods of tobacco to meet the requirements of dislocation and crossing. Put them into the mobile curing barn. It is recommended to load 260 rods of tobacco and wait for curing.

[0049] S300: The yellowing period includes early y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com