Preparation and application of water stabilizing and purifying type aquatic product fermented feed

A water stabilization and purification type, fermented feed technology, applied in applications, animal feed, animal feed, etc., can solve the problems of less attention to water quality, less control and quality evaluation of fermentation crafts, etc., to improve and stabilize water quality, enhance Utilization rate and value, effect of pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

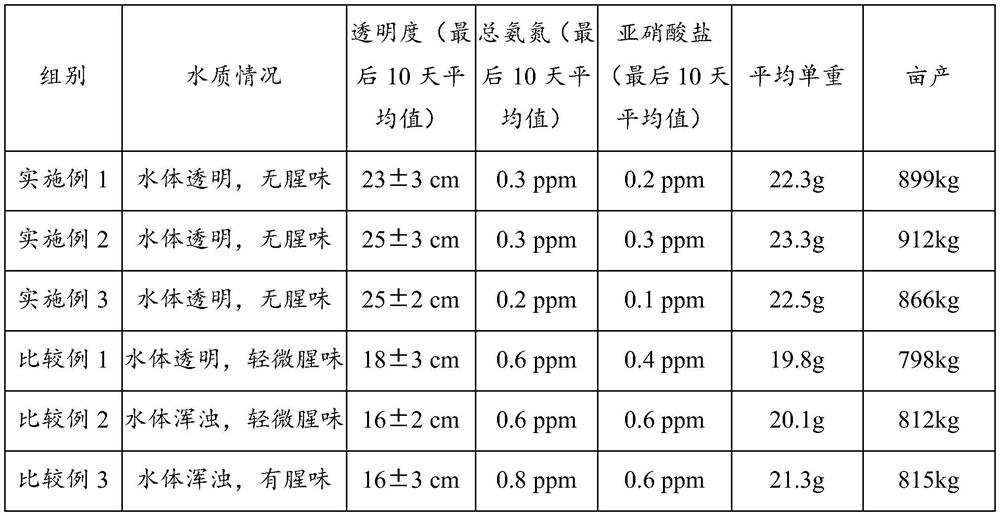

Examples

Embodiment 1

[0032] 1) Dry heat sterilize 20kg of corn, 10kg of soybean meal, 5kg of meat and bone meal, and 65kg of bran at a temperature above 100°C for 1 hour, crush them through a 60-mesh sieve, and then mix corn, soybean meal, meat and bone meal and bran to make raw materials Carrier 100 kg;

[0033] 2) Weigh 0.1 kg each of Bacillus subtilis, Bacillus licheniformis, Bacillus coagulans, saccharomyces, Clostridium butyricum, 0.5 kg each of bromelain and fungal cellulase, and make 1.5 kg of strain nutrient after crushing and mixing ;

[0034] 3) The raw material carrier is added in the bacterial liquid nutrient and mixed and stirred to make 101.5 kilograms of mixed feed;

[0035] 4) The mixed feed is inspected, weighed, bagged, packaged, and put into storage;

[0036] 5) When using, add 101.5 kg of mixed feed to 2.5 times of water, open at 30°C for aerobic fermentation for 1 day, and seal it at 30°C for anaerobic fermentation for 1 day to make 350 kg of wet fermentation feed. After fer...

Embodiment 2

[0038] 1) Dry heat sterilize 20kg of corn, 20kg of soybean meal, 5kg of meat and bone meal, and 55kg of bran at a temperature above 100°C for 1 hour, crush them through a 60-mesh sieve, and then mix corn, soybean meal, meat and bone meal and bran to make raw materials Carrier 1000 kg;

[0039] 2) Weigh 0.1 kg each of Bacillus subtilis, Bacillus licheniformis, Bacillus coagulans, saccharomyces, Clostridium butyricum, 0.5 kg each of bromelain and fungal cellulase, and make 1.5 kg of strain nutrient after crushing and mixing ;

[0040] 3) The raw material carrier is added in the bacterial liquid nutrient and mixed and stirred to make 101.5 kilograms of mixed feed;

[0041] 4) The mixed feed is inspected, weighed, bagged, packaged, and put into storage;

[0042] 5) When using, add 101.5 kg of mixed feed to 2.5 times of water, open at 30°C for aerobic fermentation for 1 day, and seal it at 30°C for anaerobic fermentation for 1 day to make 350 kg of wet fermentation feed. After fe...

Embodiment 3

[0044] 1) Dry heat sterilize 20kg of corn, 10kg of soybean meal, 10kg of meat and bone meal, and 60kg of bran at a temperature above 100°C for 1 hour, crush them through a 60-mesh sieve, and then mix corn, soybean meal, meat and bone meal and bran to make raw materials Carrier 100 kg;

[0045] 2) Weigh 0.1 kg each of Bacillus subtilis, Bacillus licheniformis, Bacillus coagulans, saccharomyces, Clostridium butyricum, 0.5 kg each of bromelain and fungal cellulase, and make 1.5 kg of strain nutrient after crushing and mixing ;

[0046] 3) The raw material carrier is added in the bacterial liquid nutrient and mixed and stirred to make 101.5 kilograms of mixed feed;

[0047] 4) The mixed feed is inspected, weighed, bagged, packaged, and put into storage;

[0048] 5) When using, add 101.5 kg of mixed feed to 2.5 times of water, open at 30°C for aerobic fermentation for 1 day, and seal it at 30°C for anaerobic fermentation for 1 day to make 350 kg of wet fermentation feed. After ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com