Anti-rolling forming device for regenerated rubber production and processing

A technology of recycled rubber and molding device, which is applied in the field of molding devices for recycled rubber production and processing, can solve the problems of inability to adjust the top plate for blanking, reduce the practicability of the molding device for processing, etc., and achieves rapid blanking, enhanced stability, and improved stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

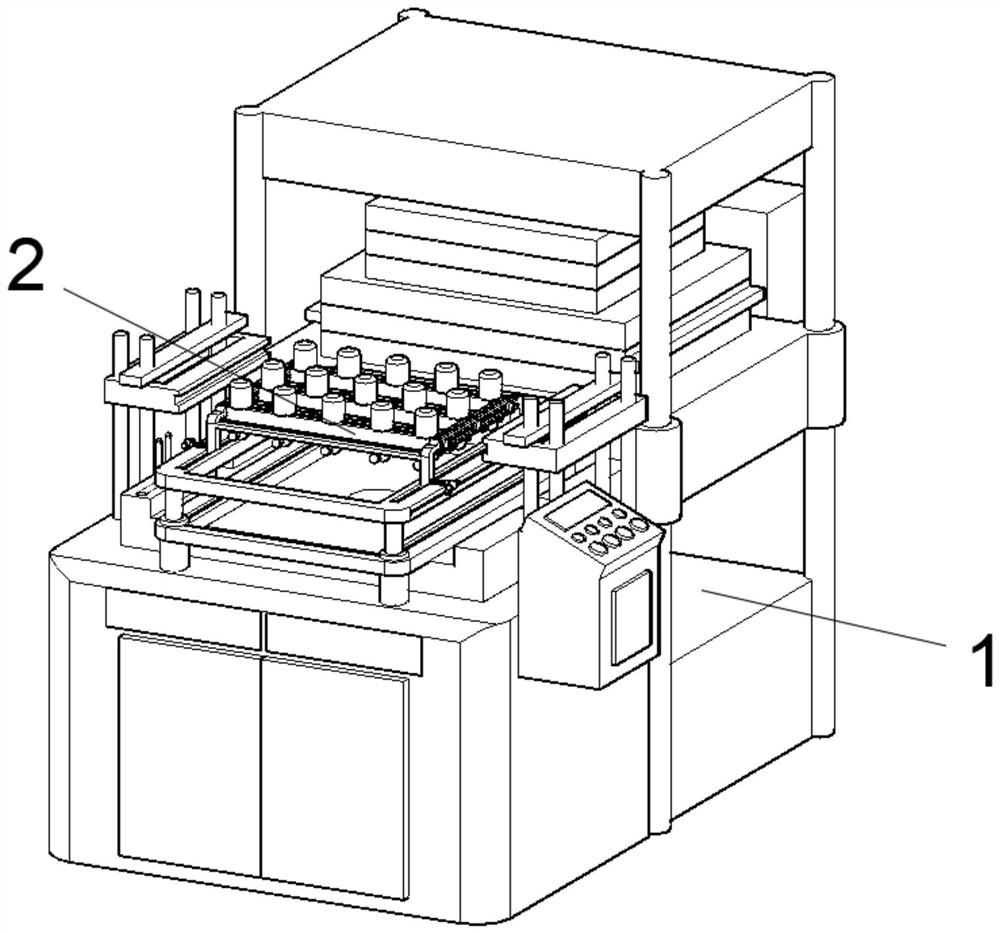

[0037] see figure 1 , an embodiment provided by the present invention: an anti-rolling regenerated rubber molding device for production and processing, including a regenerated rubber molding machine 1 and a blanking device 2, and the unloading device 2 is fixedly installed on the regenerated rubber molding machine 1 surface center;

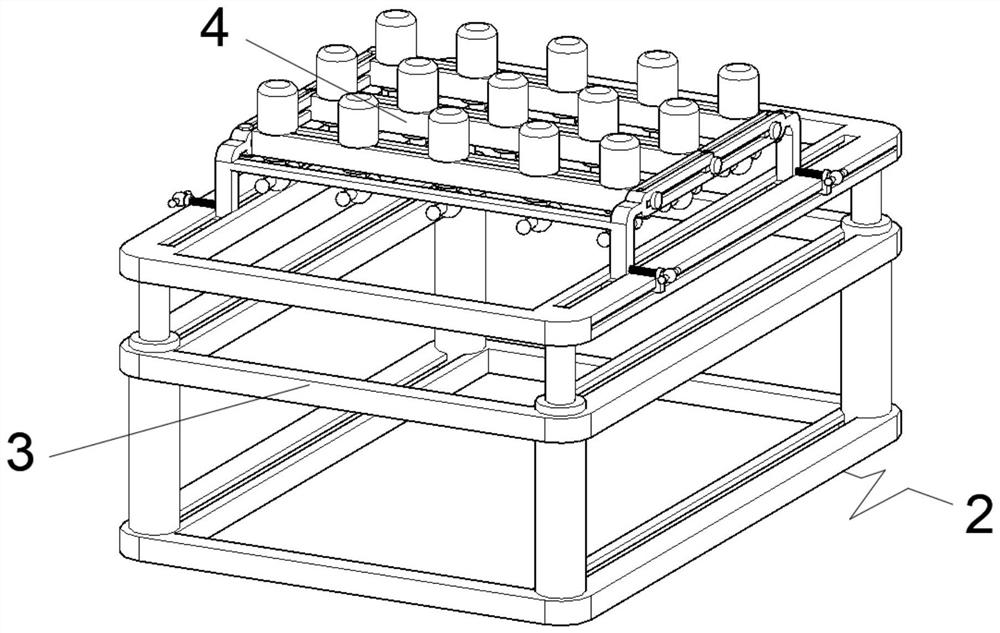

[0038] see figure 2 , the inside of the blanking device 2 includes a limit frame 3 and a blanking frame 4, and the blanking frame 4 is slidably installed on the upper surface of the limit frame 3;

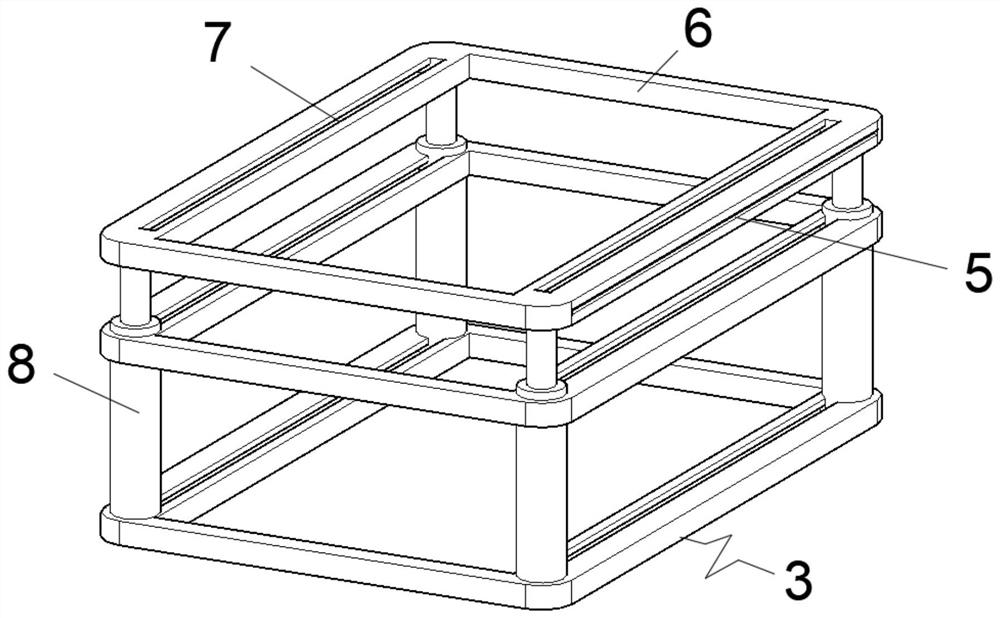

[0039] see image 3, the inside of the limit frame 3 includes a first limit chute 5, a support frame 6, a first limit slide 7 and a hydraulic cylinder 8, and the hydraulic cylinder 8 is fixedly installed on the inner bottom of the support frame 6, and the support frame 6 The four corners of the bottom surface of the hydraulic cylinder are slidably inserted into the top surface of the hydraulic cylinder 8, the first limit slideway 7 is opened on bot...

Embodiment 2

[0056] On the basis of Example 1, such as Figure 10 As shown, the edge of the bottom surface of the extruding column 23 is fixedly connected with a positioning clamp 30 , and both sides of the center of the upper surface of the limiting slide 22 are provided with positioning tooth grooves 31 .

[0057] When implementing this embodiment, when adjusting the position of the extruding column 23 according to the size of the mold, first turn the second extruding screw 25 in the opposite direction to loosen the bottom surface of the limit slide plate 22, and then pull the extruding column 23 to drive the first The two extruding screws 25 slide laterally at the inner center of the limit slide plate 22. After the position of the extrude column 23 is determined, the positioning clamp plate 30 on the bottom surface of the extrude column 23 and the positioning tooth groove 31 on the upper surface of the limit slide plate 22 Then the second extruding screw 25 is screwed and fastened to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com