Novel electronic packaging box inner liner and preparation method thereof

A packaging box, electronic technology, used in packaging, transportation and packaging, internal accessories, etc., to avoid damage, excellent thermal insulation and mechanical properties, and improve strength and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

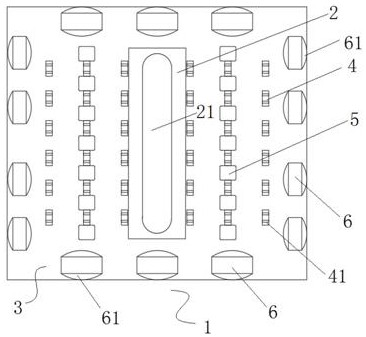

[0036] A new type of electronic packaging box inner liner is characterized in that it includes a body 1, a partition 2 is provided in the middle of the body, and a first digging part 21 is provided in the middle of the partition; the two sides of the partition are symmetrical An installation area 3 is provided; limit protrusions 4 are symmetrically arranged in the installation area, and limit grooves 41 are symmetrically arranged on the limit protrusions; limit buffers 5 are arranged between adjacent limit protrusions;

[0037] Reinforced buffer parts 6 are symmetrically arranged around the body, and a second digging part 61 is arranged inside the reinforced buffer part.

[0038] A third digging part (not marked) is arranged inside the limit buffer part.

[0039] Both sides of the reinforcing buffer part are symmetrically provided with arc-shaped surfaces 61 to counteract part of the acting force.

[0040] The dredging directions of the first dredging part and the second dred...

Embodiment 2

[0044] A preparation method for the inner liner of the novel electronic packaging box of embodiment 1, characterized in that it comprises the following preparation methods:

[0045] S1. Prepare blister material;

[0046] S2. Blister processing and molding;

[0047] The plastic-absorbing material includes the following parts by weight: polyethylene terephthalate 100, toughening agent 19, whitening agent 16, reinforcing agent 29; the reinforcing agent is calcium carbonate hollow microspheres and graphene hollow Mixture of microspheres.

[0048] Further, in the reinforcing agent, the mass ratio of calcium carbonate hollow microspheres to graphene hollow microspheres is 4:1.

[0049] Further, the toughening agent is isophthalic acid; the whitening agent can be realized by any prior art.

[0050] Further, the preparation method of the plastic-absorbing material comprises the following steps:

[0051] S11. Enhancer pretreatment preparation;

[0052] S12. The plasticizer, whiten...

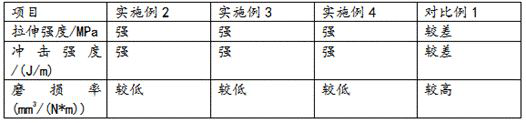

Embodiment 3

[0059] This embodiment provides a preparation method of a new electronic packaging box inner liner identical to that of Embodiment 2, the difference is that the plastic-absorbing material includes the following components in parts by weight: polyethylene terephthalate 100, Toughening agent 18, whitening agent 13, reinforcing agent 26; the reinforcing agent is a mixture of calcium carbonate hollow microspheres and graphene hollow microspheres.

[0060] Further, in the reinforcing agent, the mass ratio of calcium carbonate hollow microspheres to graphene hollow microspheres is 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com