Main anchoring pouring positioning formwork and method for air shield dam installation engineering

A technology for installation engineering and positioning templates, which is applied in sea area engineering, water conservancy engineering, infrastructure engineering, etc., to achieve the effects of improving efficiency, good installation quality, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] For an inland river in a certain province, a gas shield dam with a water retention of 3.8 meters and a length of 410 meters was built. For this reason, the project works well and creates high-quality projects.

[0040] The main anchor pouring positioning template and method of the present invention are adopted to solve the problem of anchor foundation.

[0041] The main anchoring pouring positioning formwork is made of 304 stainless steel.

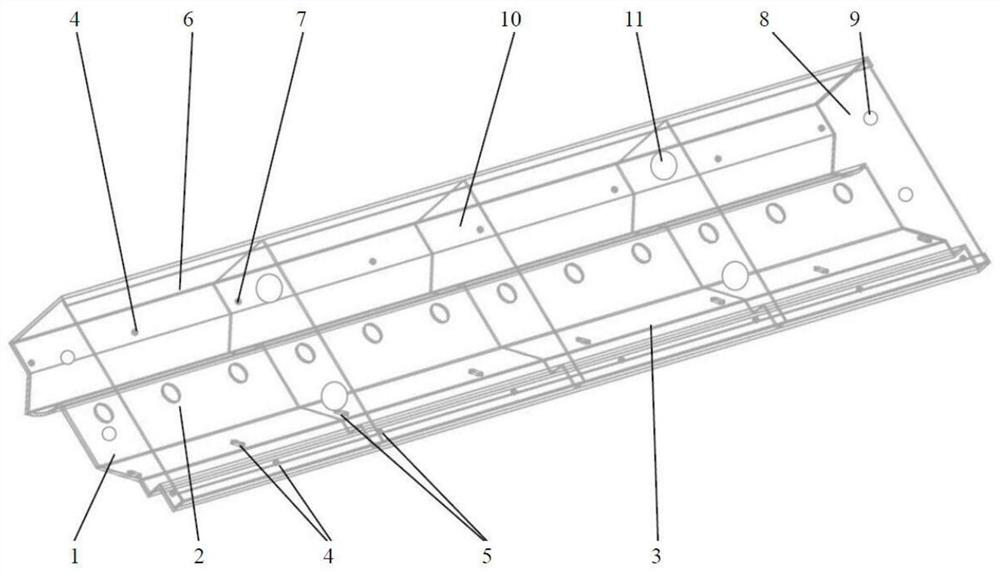

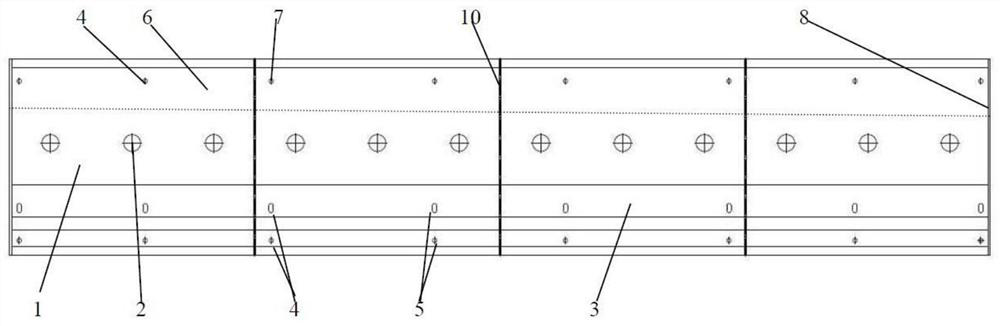

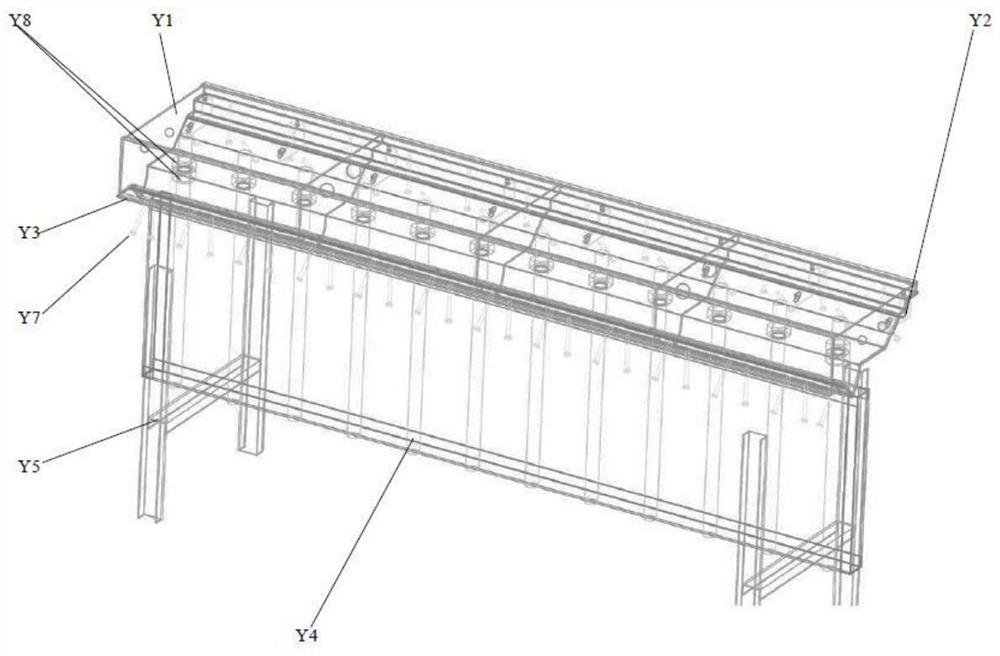

[0042] Such as Figure 1~2 As shown, a main anchoring and pouring positioning formwork of a gas shield dam installation project includes a main anchoring bolt positioning plate / base plate 1, which is provided with formwork positioning holes 2; a front baffle plate 3, which is provided with two parallel rows and each Alternately distributed exhaust holes 4 and positioning holes 5 for embedded parts at the root; rear baffle 6, which is provided with a row of alternately distributed exhaust holes 4 and positioning holes 7 for embedde...

Embodiment 2

[0062] A 3.0-meter-retaining air shield dam with a length of 40 meters adopts the main anchorage pouring positioning formwork and method of the present invention.

[0063] The main anchoring pouring positioning formwork is made of Q355B carbon steel.

[0064] Except that the designed size of the main anchoring pouring positioning formwork is changed, the others are the same as in Embodiment 1.

[0065] The invention changes the main anchor fixing position and construction method of the gas shield dam, which is convenient and precise in positioning, and the construction is simple and convenient. The formwork, root embedded parts, wedge embedded parts, anchor row and bracket are set together with the steel cage, and concrete is poured at one time. . The construction efficiency is high, the formwork can be recycled, the project cost is saved, and the installation quality of the gas shield dam is good.

[0066] The production process of the invention is simple and stable, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com