Mine goaf area water plant foundation treatment method

A foundation treatment and goaf technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve problems such as air bubbles, cement compaction, and low cement density, and achieve the effects of convenient and simple use, material saving, and tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A ground treatment method for a water plant in a mine goaf area, comprising the following steps:

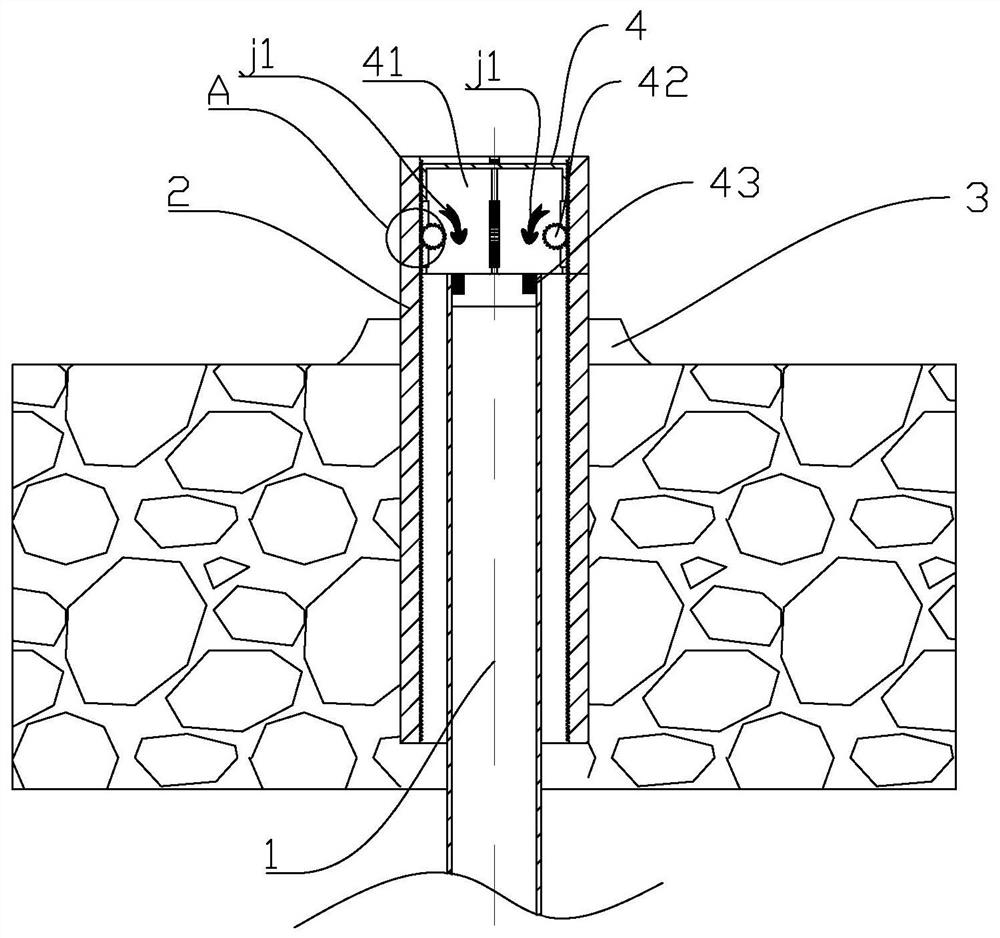

[0027] S1. Preparations before piling: Determine the location of piling through design, and then excavate foundation pits manually or with large machines. When the depth reaches 1 meter to 1.2 meters, stop excavation and pour through ring-shaped molds at the entrance of the foundation pit The reinforced concrete well circle 3 is produced, and the reinforced concrete well circle 3 can be 0.06 to 0.1 meters above the water level.

[0028] What needs to be ensured in the above steps is that the upper end surface of the reinforced concrete well ring 3 is parallel to the horizontal plane, the hole of the reinforced concrete well ring 3 is cylindrical, and the cylindrical hole is perpendicular to the horizontal plane.

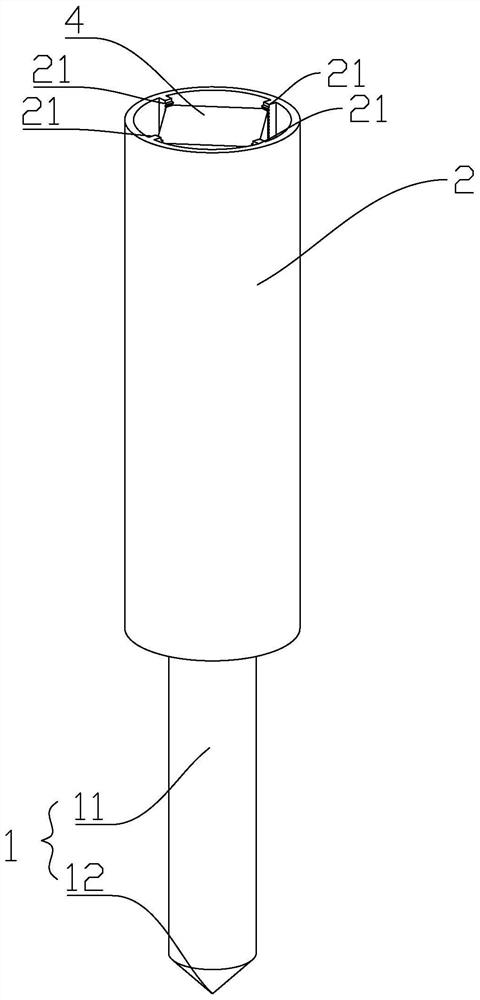

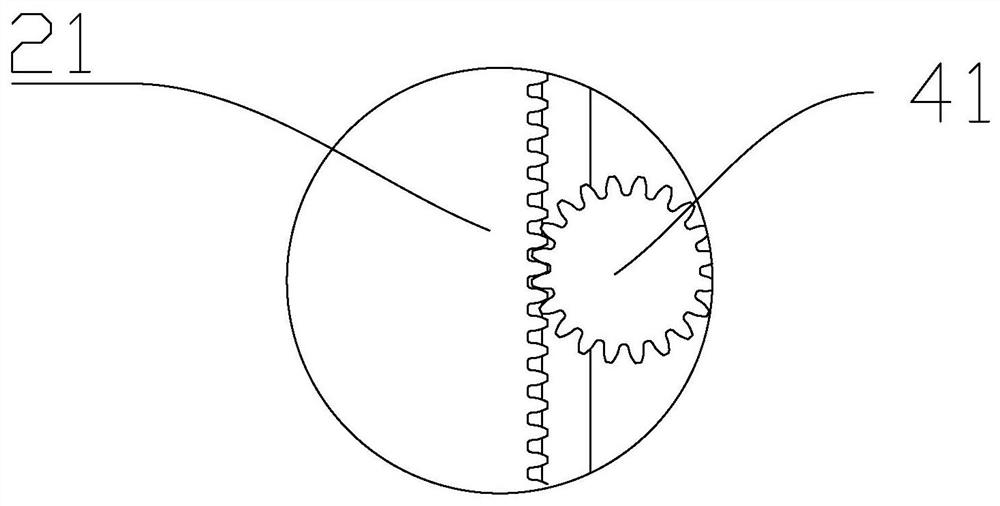

[0029] S2. Drilling: vertically drive into the outer ring tube 2 along the reinforced concrete well ring 3, the outer diameter of the outer ring tube 2 is the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com