Distributed sound-sensitive optical fiber sensor and manufacturing method thereof

An optical fiber sensor, distributed technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of insensitivity to sound and vibration, high cost, short detection distance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

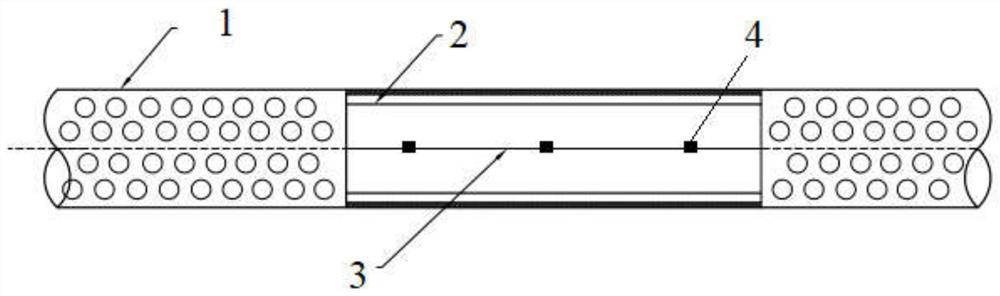

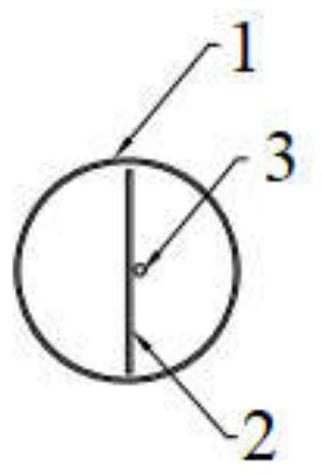

[0032] A kind of distributed sound-sensitive optical fiber sensor structure of the present embodiment, such as figure 1 with 2 shown, where figure 1 The middle part is a schematic diagram of an internal cross-section, including a hollow metal or non-metal protective sleeve 1 , a metal or non-metal sheet 2 placed in the protective sleeve 1 , and an optical fiber 3 laid on the sheet 2 . Described optical fiber 3 is formed by high-purity quartz through high-temperature melting and drawing, and its own air or water pressure resistance is very strong. This embodiment is applied to high-pressure environments such as deep sea and pressure pipelines. Stainless steel sleeves and sheets are used to protect the optical fiber 3 from external force damage. The optical fiber 3 directly contacts other media such as water, and the sound or vibration transmitted through water It will directly propagate to the optical fiber 3, thereby improving the coupling efficiency between the sound or vib...

Embodiment 2

[0042] The difference between this embodiment and embodiment 2 is that it is used in a corrosive environment, so a protective sleeve 1 and a sheet 2 of non-metallic anti-corrosion material epoxy resin are used; and a hollowed-out protective sleeve 1 without an axial opening is adopted, and used The thin slice is implanted in the hollow protective casing 1 by traction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com