Efficient soaking device of humidifying bottles for pneumology department

A humidification bottle, high-efficiency technology, applied in water supply equipment, sanitary equipment for toilets, chemistry, etc., can solve the problems of waste of disinfectant, inability to control humidification bottles, and low space utilization of disinfection tanks, so as to improve the flushing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

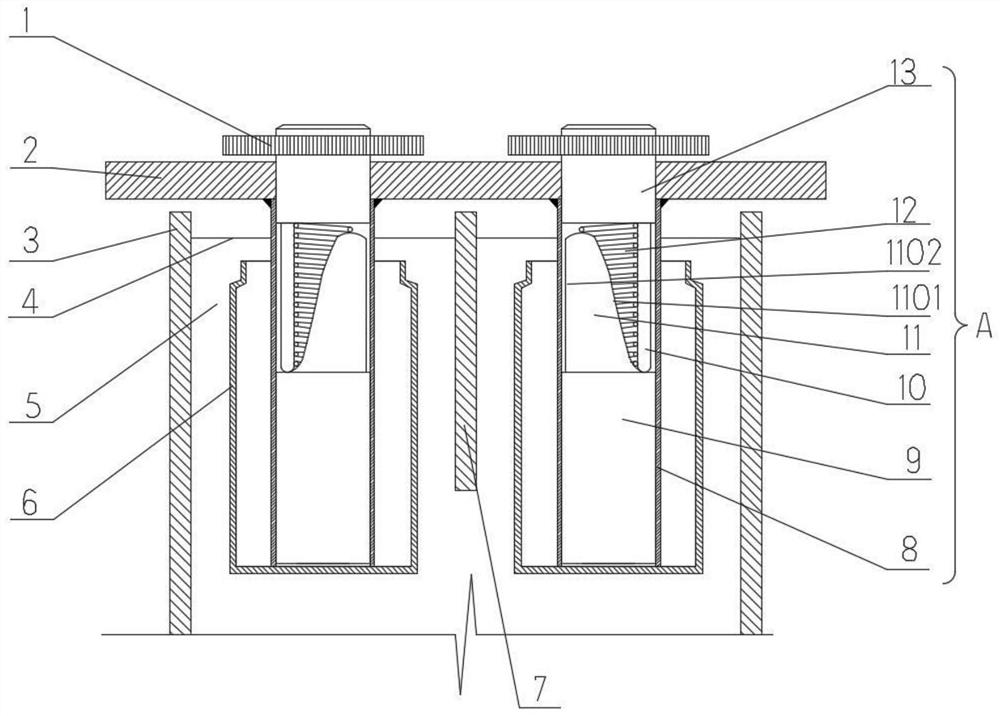

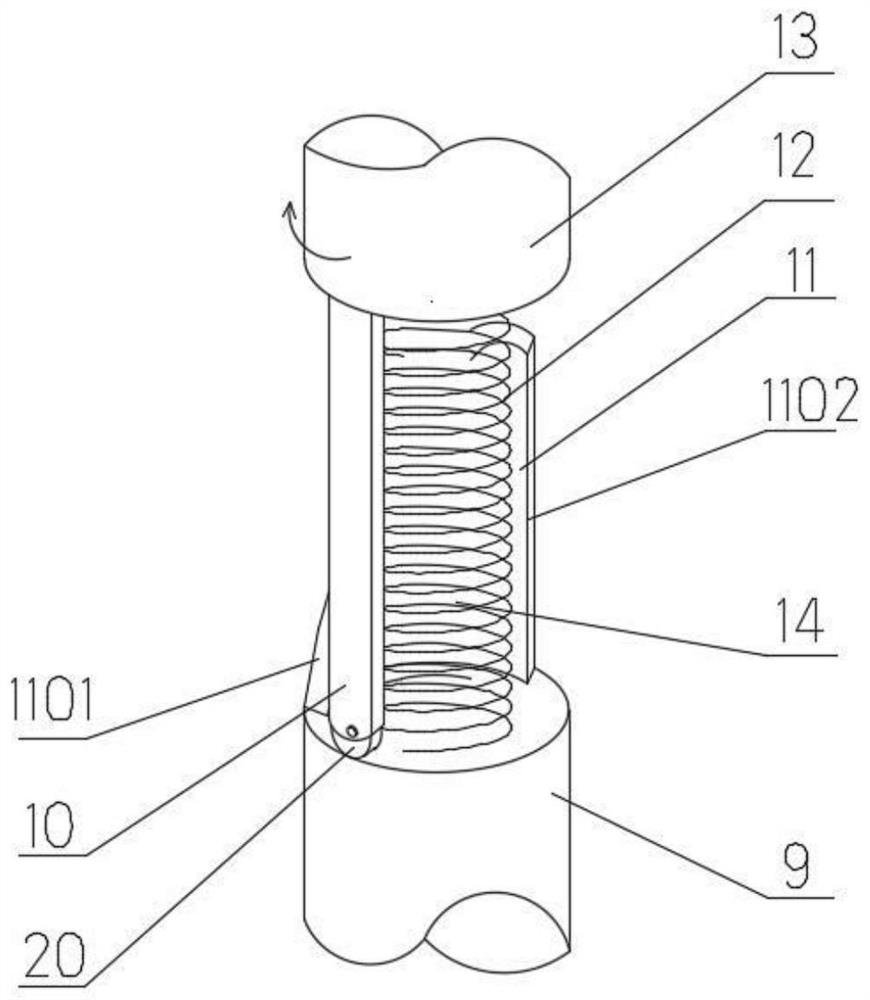

[0027] Such as figure 1 As shown, a high-efficiency soaking device for a respiratory humidification bottle 6 in this embodiment includes a rectangular soaking tank 3 (only part is shown in the figure for illustration). The depth of the soaking tank 3 is 1.5 to 2 times the height of the humidification bottle 6, so as to adapt to the vertical posture of the humidification bottle 6 for immersion and continuous reciprocating ups and downs to achieve the purpose of eliminating blind spots in the dead angle of soaking and disinfection. The length and width of the soaking tank 3 are based on the humidification bottles 6 to be sterilized in the hospital that can be processed in batches. The immersion tank 3 is provided with partition plates 7 staggered along its own length and width, so that the inner cavity of the immersion tank 3 can be divided into multiple soaking postures for a single humidification bottle 6 to be soaked and sterilized separately by the partition plate 7 Limit c...

Embodiment 2

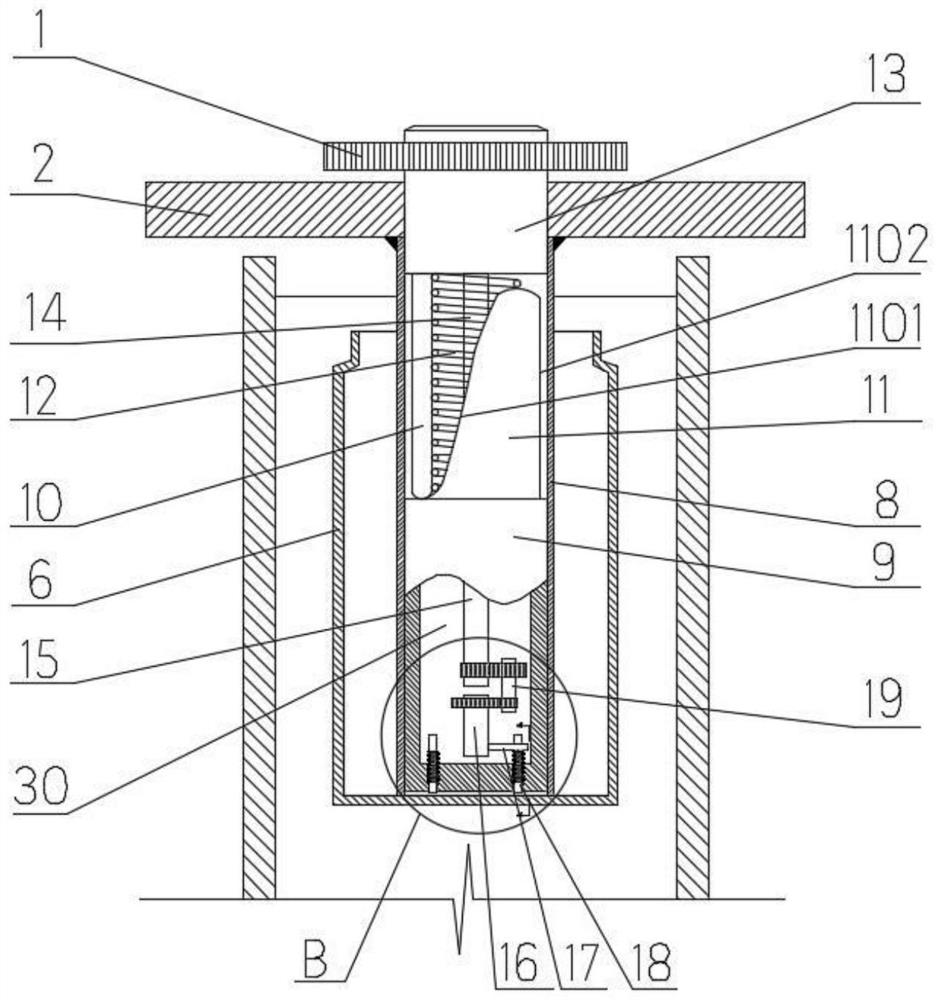

[0040] Such as image 3 As shown, the main structure of this embodiment is similar to that of Embodiment 2, the only difference is that this embodiment is provided with a plurality of pressure rods 18 at the bottom of the sliding shaft 9, the sliding shaft 9 is a hollow shaft and forms a bottom cavity 30 at its lower part . In the bottom cavity 30, there is an actuator for driving the pressure rod 18 to extend out sequentially to sink the humidification bottle 6, and the actuator is linked with the first rotating shaft 13, so that the first rotating shaft 13 can drive the sliding shaft 9 each time. When moving down, a pressing rod 18 is driven to stretch out the pressing humidification bottle 6, so that compared with Embodiment 1, the present embodiment sinks the humidifying bottle 6 through the pressing rod 18, because the pressing rod 18 has a smaller The area of the end wood reduces the contact area with the bottom of the humidification bottle 6 and reduces the dead angl...

Embodiment 3

[0047] The main structure of this embodiment is the same as that of Embodiment 1, the difference is:

[0048] Such as Figure 8 As shown, in the present embodiment, a longitudinal blind hole is provided at the lower end of the push rod 10, and a compression spring 28 and a rolling ball 29 in a compressed state are arranged in the blind hole, and the outer edge of the upper end of the sliding shaft 9 passes through the rolling ball 29 and Slidingly fit with the slope portion 1101 of the pushed piece 11 to reduce friction. Compared with Embodiment 1, the sliding direction of the rolling ball 29 in this embodiment is not limited, so that the push rod 10 has a smaller extrusion force in the sliding fit of the slope portion 1101 , further improving the stability of the structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com