Novel husked rice color sorting separation process with high quality and high benefit

A high-efficiency, high-quality technology, applied in the field of color separation, can solve problems such as the inability to select red rice and green rice, and the inability to make better use of value, so as to reduce processing costs, improve product quality, and improve economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

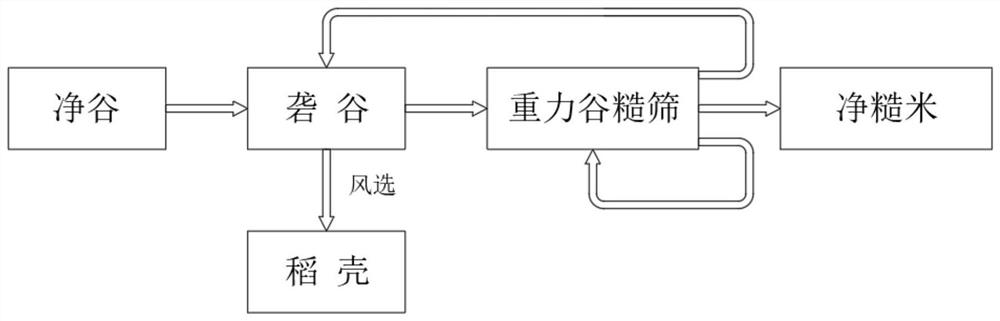

[0039] first, figure 2 It is a flow chart for the separation of paddy rice in the prior art, which has the step of hulling and husking, and uses a gravity paddy sieve to separate brown rice from the paddy paddy mixture, but it cannot be color sorted, resulting in a lot of impurities in the brown rice .

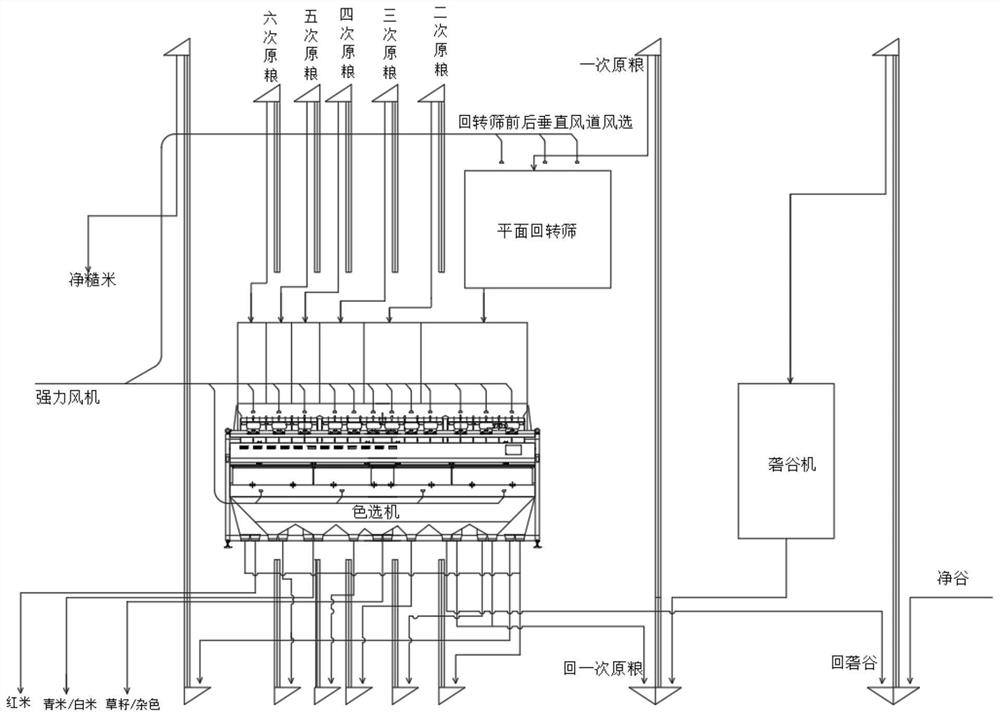

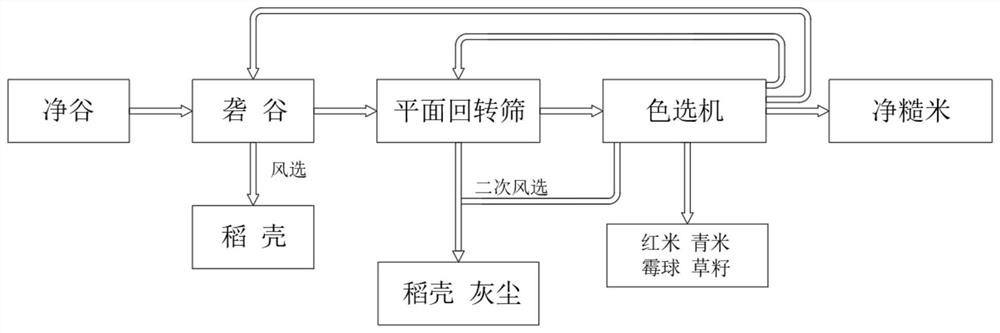

[0040] Such as figure 1 with image 3 As shown, a kind of high-quality and high-efficiency novel paddy color separation separation process proposed by the present invention comprises the following steps:

[0041] S1. Material supply: provide clean grain containing impurities that meet the processing requirements;

[0042] S2, husking: using a husking machine to hustle the clean grain;

[0043] S3. Sieving: Use a plane rotary sieve to sieve the husked grains, so that the husked grains are separated from rice husks and dust;

[0044] S4, color sorting and sorting: use the color sorter to sort out relatively different-colored particles according to the difference in optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com