Solid waste recovery and comprehensive treatment device

A solid waste, comprehensive treatment technology, applied in the direction of drying solid materials, drying gas arrangement, drying solid materials without heating, etc. Improve work efficiency and performance, and the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

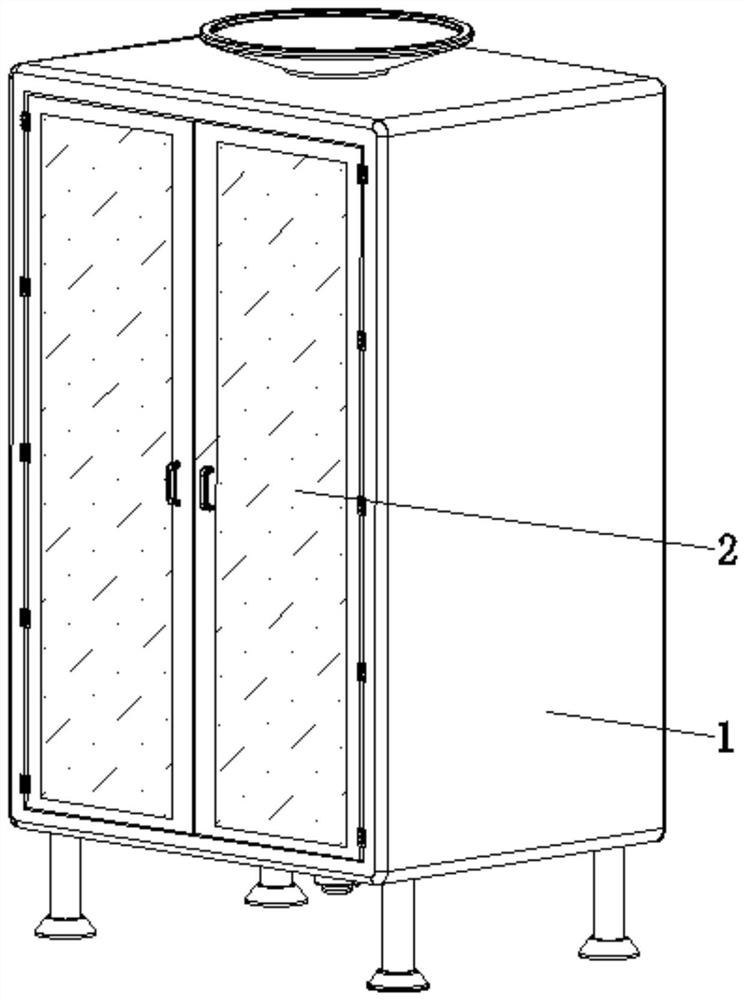

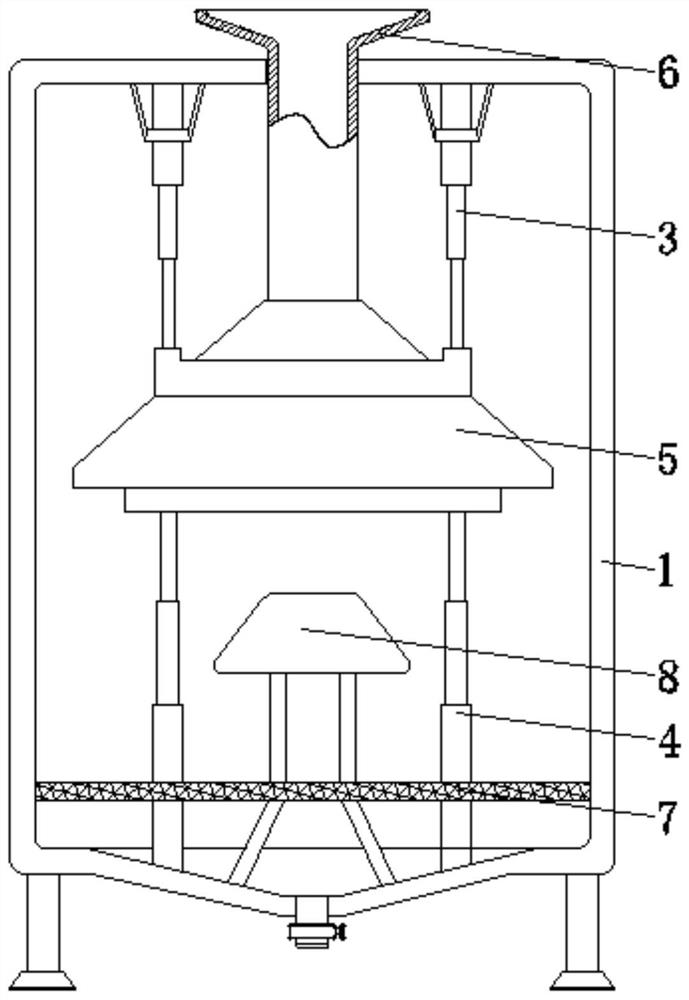

[0031] see Figure 1-7 , the present invention provides a technical solution: a solid waste recycling comprehensive treatment device, comprising a cabinet body 1, a cabinet door 2, and the cabinet door 2 is arranged on the surface side of the cabinet body 1;

[0032] The interior of the cabinet 1 is provided with an upper hydraulic cylinder 3, a lower hydraulic cylinder 4, a waste treatment device 5, a feed hopper 6, a sieve plate 7, and a conical boss 8, and the upper hydraulic cylinder 3 is arranged on the top of the inner wall of the cabinet 1. The lower hydraulic cylinder 4 is arranged at the bottom of the inner wall of the cabinet body 1, the bottom of the waste treatment device 5 is fixedly connected with the working end of the lower hydraulic cylinder 4, and the surface top of the waste treatment device 5 is fixedly connected with the working end of the upper hydraulic cylinder 3, and the feeding The hopper 6 is fitly connected to the top center of the waste treatment d...

Embodiment example 2

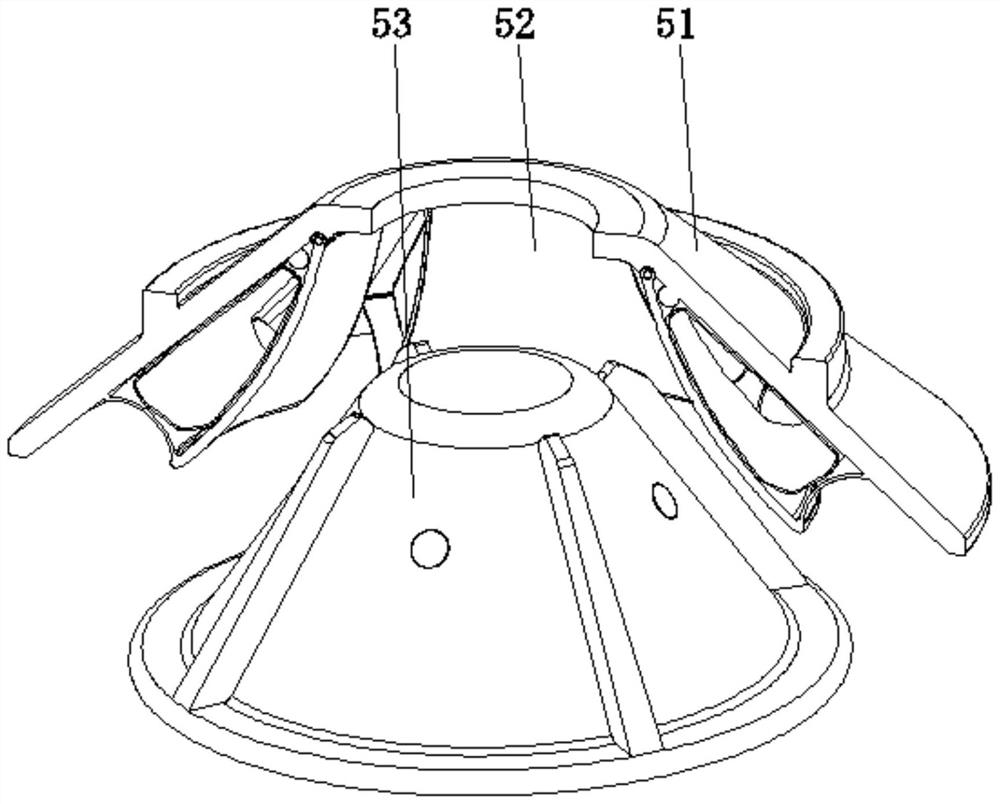

[0034] The waste treatment device 5 is provided with a conical pressing device 51, an inner cavity 52, and a conical base device 53. The surface top of the conical pressing device 51 is fixedly connected with the working end of the upper hydraulic cylinder 3, and the inner cavity 52 is provided in the conical pressing area. The inner central position of the device 51, the bottom of the conical base device 53 is fixedly connected with the working end of the lower hydraulic cylinder 4, and the conical base device 53 is connected with the conical pressing device 51. After entering the feed hopper 6, it freely falls into the inner cavity 52 by its own gravity, and then uses the conical pressing device 51 at the working end of the upper hydraulic cylinder 3 to move downward. At this time, the conical base device 53 and the conical pressing device 51 to cooperate, and then the waste is quickly compressed, and the water is squeezed out to remove the water in time, and the working end ...

Embodiment example 3

[0036]The conical pressing device 51 is provided with a top cap 511, a pressing plate device 512, a rubber strip 513, an air bag 514, and an arc-shaped elastic member 515. The inner wall of the top cap 511 is close to the top of the platen device 512. The air bag 514 is arranged between the two sides corresponding to the inner wall of the top cap 511 and the surface of the platen device 512. Between the corresponding two sides, when the working end of the upper hydraulic cylinder 3 drives the top cap 511 to move downward, the joint action of the pressing plate device 512 and the conical base device 53 compresses the waste material, and at the same time, the moisture in the waste material is squeezed out , and the rubber strip 513 and the arc-shaped elastic member 515 are pressed to provide elastic force, which increases the pressure of the pressing plate device 512 on the waste material and helps to compress the waste material, and the rotating pressing plate device 512 will pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com