High-thermal-conductivity PCR tube and preparation process thereof

A technology with high thermal conductivity and preparation technology, which is applied in the field of reaction tubes, can solve the problems of non-corrosion resistance and high price, and achieve the effects of high thermal conductivity, excellent thermal conductivity and wear resistance, excellent thermal conductivity and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

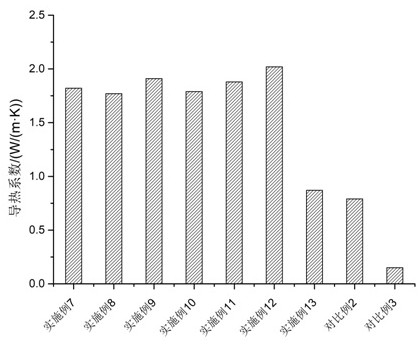

Examples

Embodiment 1

[0040] A method for preparing a thermally conductive material, comprising the steps of:

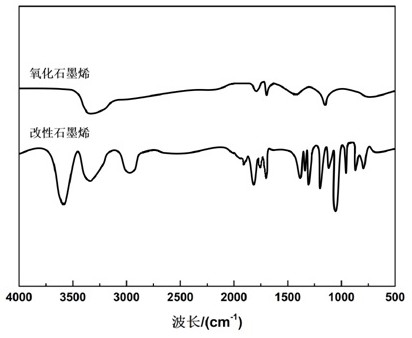

[0041] S1: Preparation of modified graphene

[0042] In parts by weight, disperse 2.5 parts by weight of graphene oxide in 35 parts by weight of DMF, then add 130 parts by weight of thionyl chloride to treat at 75°C for 8h; Drying at lower temperature to obtain functionalized graphene oxide; then 1.5 parts by weight of the above-mentioned functionalized graphene oxide, 24 parts by weight of neohesperidin, 2.5 parts by weight of triethylamine, 25 parts by weight of toluene, and 8 parts by weight of DMF were added to the container In a round-bottomed flask with a magnetic stirrer and a reflux condenser, after stirring at 75°C for 1h, reflux for 80h, cool to room temperature, wash with ethanol, and dry at 45°C to obtain modified graphene;

[0043] S2: Preparation of thermally conductive material

[0044] Dissolving 10 parts by weight of polyvinylpyrrolidone in 30 parts by weight of methylf...

Embodiment 2

[0048] A method for preparing a thermally conductive material, comprising the steps of:

[0049] S1: Preparation of modified graphene

[0050] In parts by weight, disperse 4 parts by weight of graphene oxide in 45 parts by weight of DMF, then add 160 parts by weight of thionyl chloride to treat at 80°C for 12h; Drying at lower temperature to obtain functionalized graphene oxide; then 2.5 parts by weight of the above-mentioned functionalized graphene oxide, 30 parts by weight of neohesperidin, 3.5 parts by weight of triethylamine, 30 parts by weight of toluene, and 11 parts by weight of DMF were added to the container. In a round-bottomed flask with a magnetic stirrer and a reflux condenser, after stirring at 85°C for 1 hour, reflux for 100 hours, cool to room temperature, wash with ethanol, and dry at 50°C to obtain modified graphene;

[0051] S2: Preparation of thermally conductive material

[0052] 20 parts by weight of polymethyl acrylate are dissolved in 40 parts by weig...

Embodiment 3

[0056] A method for preparing a thermally conductive material, comprising the steps of:

[0057] S1: Preparation of modified graphene

[0058] In parts by weight, 5 parts by weight of graphene oxide were dispersed in 40 parts by weight of DMF, and then 180 parts by weight of thionyl chloride was added to treat at 85°C for 12h; Drying at lower temperature to obtain functionalized graphene oxide; then 1 weight part of the above-mentioned functionalized graphene oxide, 20 weight parts neohesperidin, 2.5 weight parts triethylamine, 25 weight parts toluene, 14 weight parts DMF were added to the container In a round-bottomed flask with a magnetic stirrer and a reflux condenser, after stirring at 75°C for 1h, reflux for 120h, cool to room temperature, wash with ethanol, and dry at 50°C to obtain modified graphene;

[0059] Step S2 is the same as in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com