Preparation method of normal-temperature curing wear-resistant anticorrosive super-hydrophobic coating

A super-hydrophobic coating, room temperature curing technology, applied in the field of materials, can solve the problems such as easy to produce tiny cracks, achieve excellent self-cleaning, reduce the effect of preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

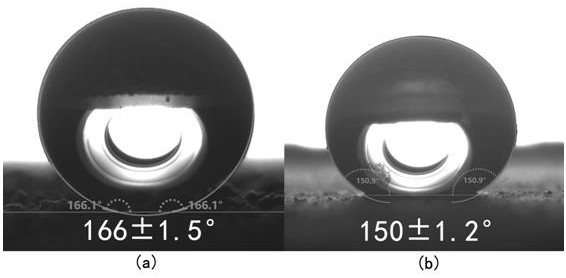

[0028] CNTs (0.05g) and POTS (0.05g) were dispersed in ethyl acetate (5g) and stirred for 1 hour. Then epoxy resin E51, curing agent D230, SiO 2 Airgel and ethyl acetate were added to the above solution at a mass ratio of 12:4:1:100. To achieve uniform dispersion, the mixture was sonicated for 15 minutes and stirred for another 30 minutes. The final solution was sprayed on the steel plate surface and cured at room temperature for 10 hours to form superhydrophobic EP-SiO 2 -CNTs-POTS coating. See Table 1.

Embodiment 2

[0030] CNTs (0.06g) and POTS (0.06g) were dispersed in ethyl acetate (5g) and stirred for 1 hour. Then epoxy resin E51, curing agent D230, SiO 2 Airgel and ethyl acetate were added to the above solution at a mass ratio of 12:4:1:100. To achieve uniform dispersion, the mixture was sonicated for 15 minutes and stirred for another 30 minutes. The final solution was sprayed on the steel plate surface and cured at room temperature for 10 hours to form superhydrophobic EP-SiO 2 -CNTs-POTS coating. See Table 1.

Embodiment 3

[0032] CNTs (0.07g) and POTS (0.07g) were dispersed in ethyl acetate (5g) and stirred for 1 hour. Then epoxy resin E51, curing agent D230, SiO 2 Airgel and ethyl acetate were added to the above solution at a mass ratio of 12:4:1:100. To achieve uniform dispersion, the mixture was sonicated for 15 minutes and stirred for another 30 minutes. The final solution was sprayed on the steel plate surface and cured at room temperature for 10 hours to form superhydrophobic EP-SiO 2 -CNTs-POTS coating. See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com