Bailey beam and distribution beam connecting device suitable for multiple occasions

A technology for connecting devices and distributing beams, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of large lateral reinforcement size, reinforcement, and inability to reinforce, so as to improve structural integrity and stability, improve structural integrity, The effect of many occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

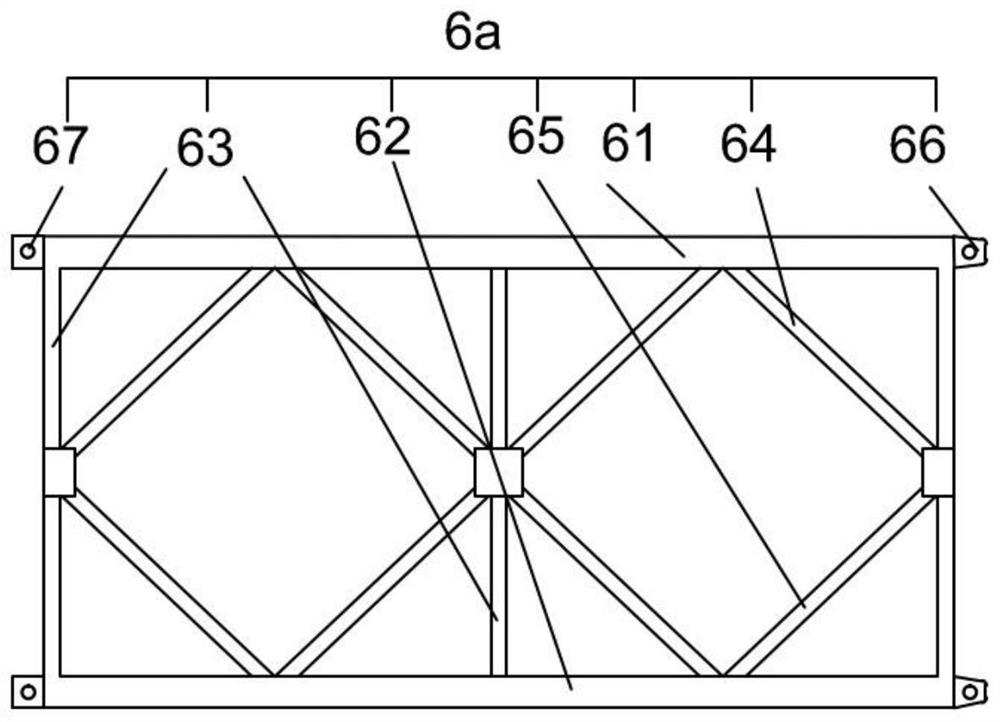

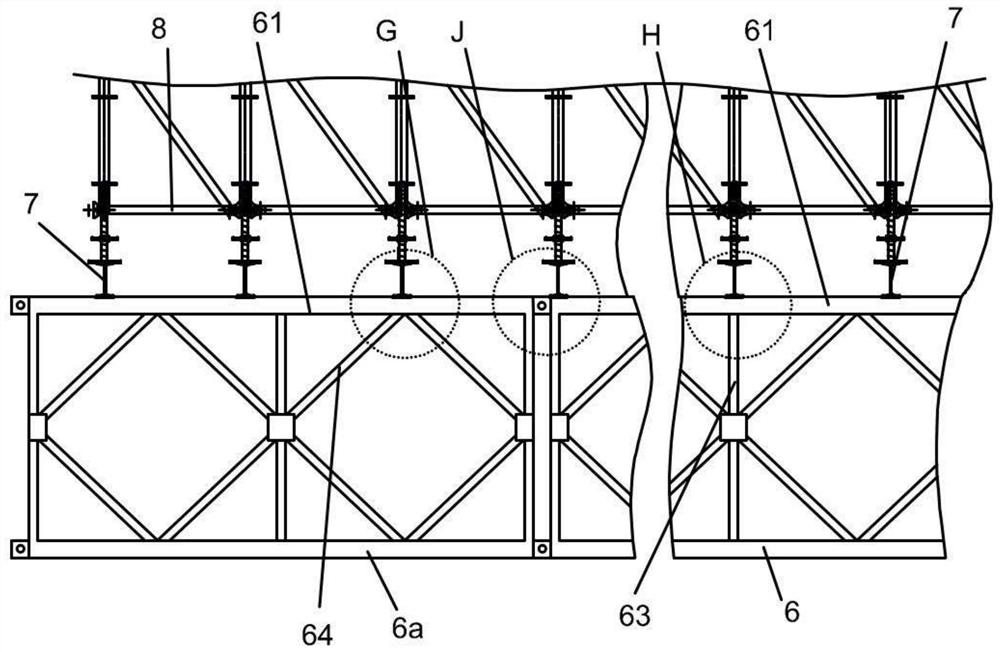

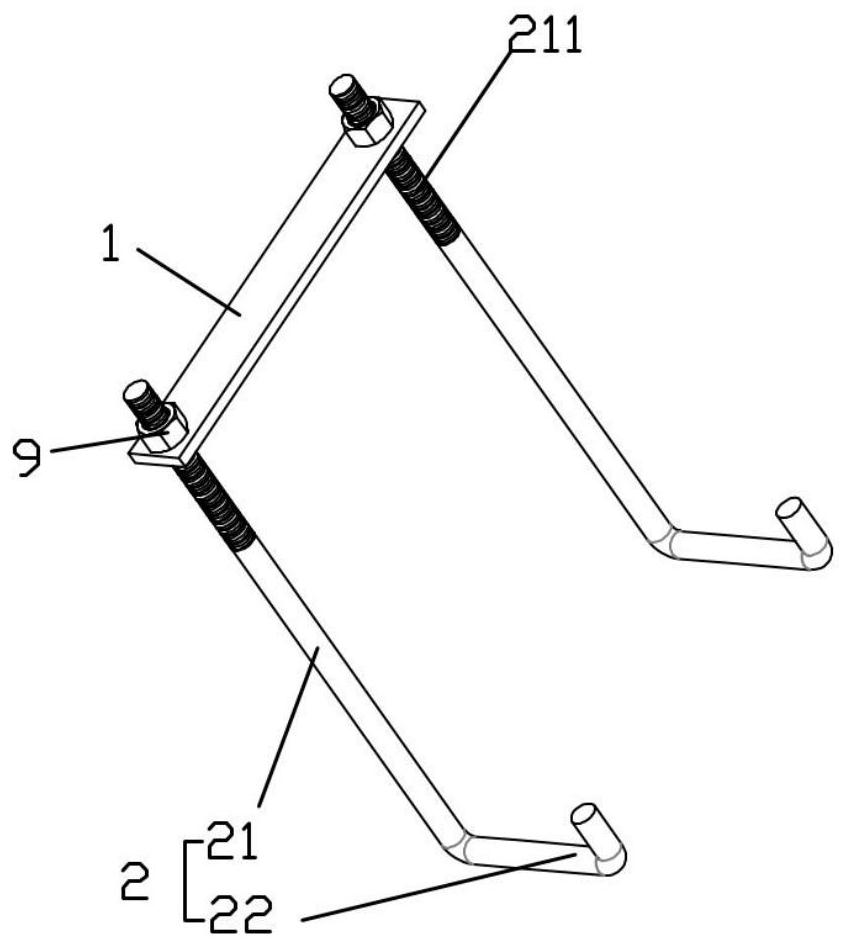

[0061] image 3 The structure of the connection device between the Bailey beam and the distribution beam of the exemplary embodiment of the present invention is shown. The connection device between the Bailey beam and the distribution beam of this embodiment includes a pressing member 1 and two fixed rods 2 arranged side by side. The fixed rod 2 includes a straight rod segment 21 and a hook-shaped segment 22 connected to one end of the straight rod segment 21. The other ends of the two straight rod segments 21 are detachably connected through the pressing member 1. The fixed rod adopts round steel, such as Figure 5 As shown, the pressing member 1 is a steel plate structure with locking holes 101 at both ends for pressing, and the straight rod section 21 of the fixing rod 2 is inserted into the locking hole 101 of the pressing member 1, and One end of the straight bar section 21 that penetrates into the pressing piece 1 is provided with a connecting thread 211, and the pressi...

Embodiment 2

[0063] Figure 6 The structure of the connection device between the Bailey beam and the distribution beam according to an exemplary embodiment of the present invention is shown. The structure of the part 1 is the same as that in the embodiment 1, and the straight rod section 21 of the fixing rod 2 is also inserted into the locking hole 101 of the pressing part 1 and locked and fixed by the nut 9, which is different from the embodiment 1. What is more, the connecting device between the Bailey beam and the distribution beam of the present embodiment also includes a connecting rod 4 fixedly connecting the two fixed rods 2, and the connecting rod 4 connects the two fixed rods 2 arranged side by side, so that the two fixed rods 2 At the same time, the connecting rod 4 and the pressing piece 1 are connected to form an overall structure. On the one hand, the structural integrity and stability of the connecting device between the Bailey beam and the distribution beam are improved, and...

Embodiment 3

[0066] The structure of the connecting device between the Bailey beam and the distribution beam of the present embodiment is further improved on the basis of embodiment 2, such as Figure 10-11 As shown, the connecting device structure between the Bailey beam and the distribution beam also includes a pressing member 1 and two fixed rods 2 arranged side by side. The fixed rod 2 includes a straight rod section 21 and a The hook section 22, the other ends of the two straight bar sections 21 are detachably connected through the pressing piece 1, and the connecting device structure between the Bailey beam and the distribution beam also includes a connecting rod 4 and a reverse hook section 23 , the connecting rod 4 is connected to the straight bar section 21, and the reverse hook section 23 is connected to the junction of the straight bar section 21 and the hook section 22, but the arrangement direction is opposite to that of the hook section 22, that is, it is opposite to the hook ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com