Multi-initiation-point multi-stage blasting fracturing method for horizontal well of shale gas reservoir

A technology for blasting fracturing and horizontal wells, which is used in earth-moving drilling, wellbore/well components, and production fluids. , Increase penetration depth, safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

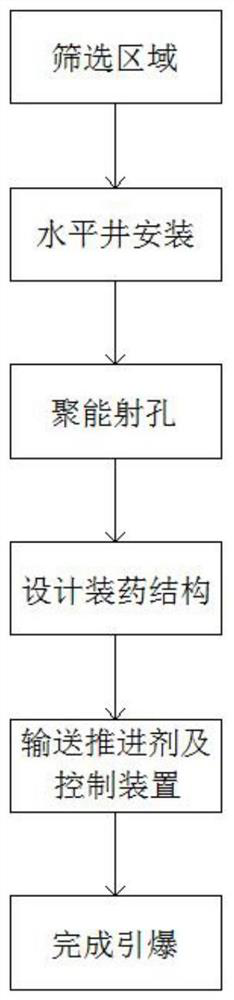

[0037] according to figure 1 As shown, this embodiment proposes a multi-stage detonation fracturing method for horizontal wells in shale gas reservoirs with multiple initiation points, including the following steps:

[0038] Step 1. Filter the area

[0039] Firstly, according to the logging data and core analysis, the geological parameters of the reservoir are obtained as a reference, and the favorable area for development is selected, and then the fracturing target interval is confirmed, and the perforation position is determined according to the obtained geological parameters of the reservoir. Parameters include reservoir rock mineral composition, porosity and permeability;

[0040] Step 2. Horizontal well installation

[0041] Determine the position of the target window according to the fracturing target interval confirmed in step 1, and then complete the drilling, cementing and completion of the shale gas horizontal well in the favorable area selected in step 1;

[0042...

Embodiment 2

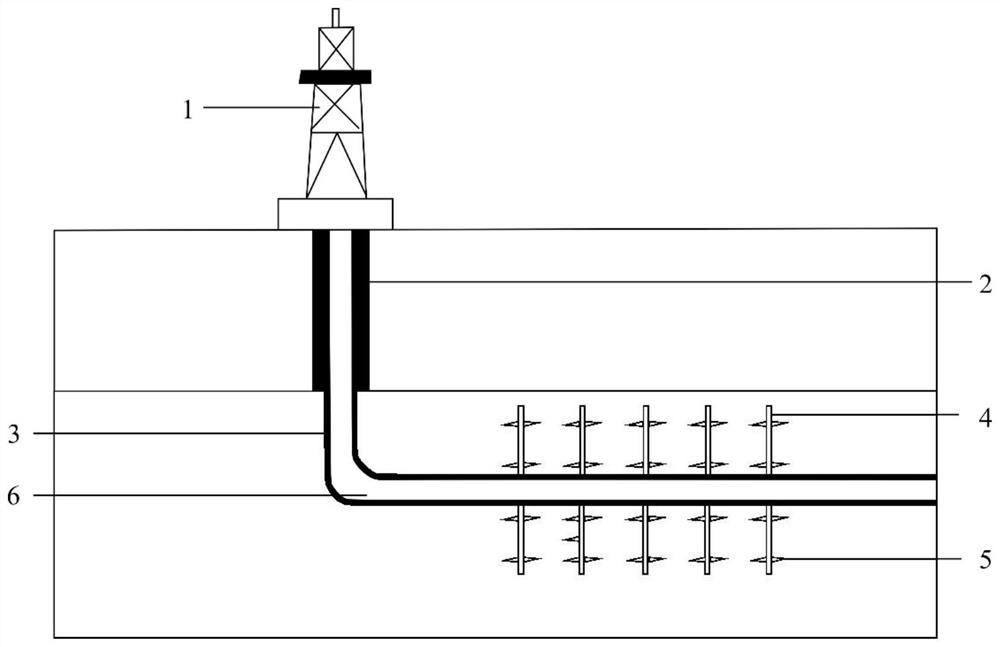

[0051] according to Figure 2-3 As shown, the first step is to obtain the geological parameters of the reservoir. Through core analysis and logging interpretation, key parameters such as mineral composition, permeability, porosity, Poisson’s ratio and gas content of the reservoir are obtained. Geological conditions select the fracturing target layer, after selection, determine the target window according to the target layer, design the horizontal well trajectory and wellbore structure, use the directional drilling rig to complete the horizontal well construction, run the casing 2 into the well, and finally inject Drilling fluid 3 is used for well completion.

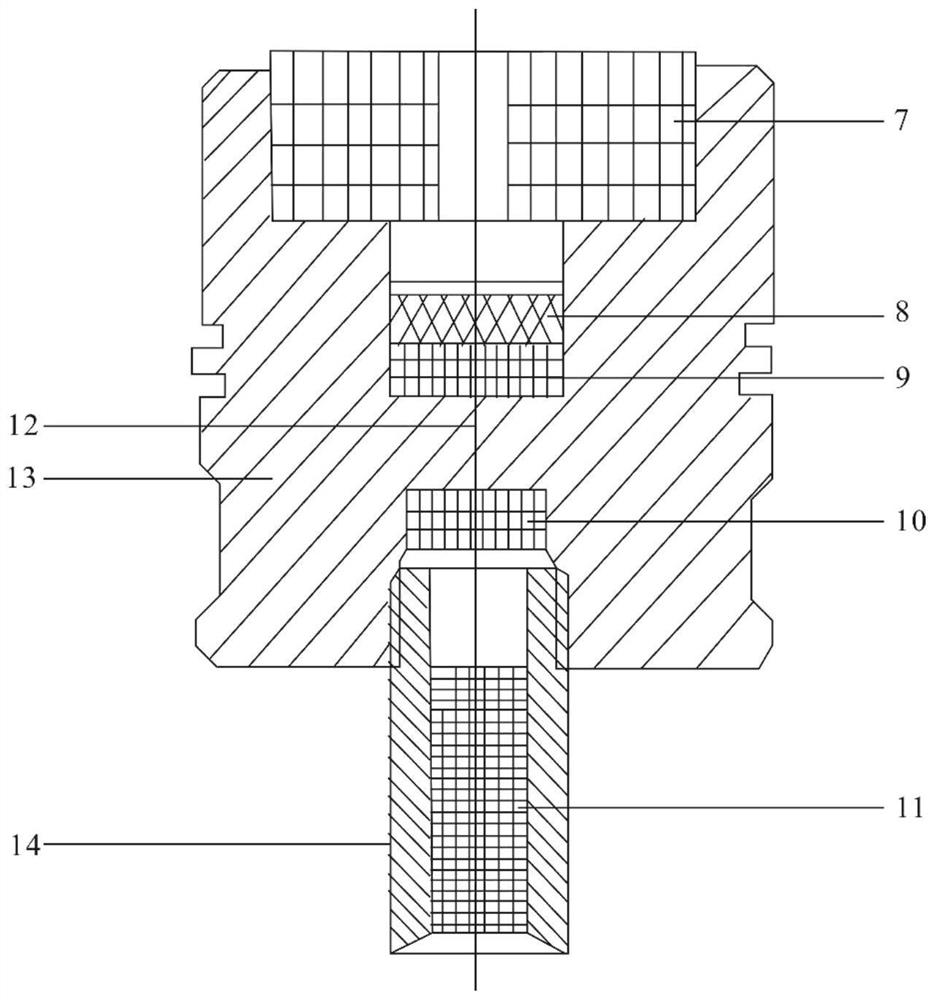

[0052] Secondly, the perforation position is determined according to the obtained reservoir geological parameters, and a higher perforation density is selected to obtain greater productivity. Due to the long horizontal section of the horizontal well, it is required that the perforation operation be successful once, so th...

Embodiment 3

[0057] according to figure 1 As shown, this embodiment proposes a multi-stage detonation fracturing method for horizontal wells in shale gas reservoirs with multiple initiation points, including the following steps:

[0058] Step 1. Filter the area

[0059] Firstly, according to the logging data and core analysis, the geological parameters of the reservoir are obtained as a reference, and the favorable area for development is selected, and then the fracturing target interval is confirmed, and the perforation position is determined according to the obtained geological parameters of the reservoir. Parameters include reservoir rock mineral composition, porosity and permeability and other reservoir space characteristics and geological parameters such as gas-bearing property;

[0060] Step 2. Horizontal well installation

[0061] Determine the position of the target window according to the fracturing target interval confirmed in step 1, and then design the horizontal well traject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com