Land-submersible dual-purpose motor

A dual-purpose, motor cavity technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increasing the length of the motor, the inability to cool the motor, etc., and achieve the effect of preventing pipeline blockage, reducing cleaning steps, and improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

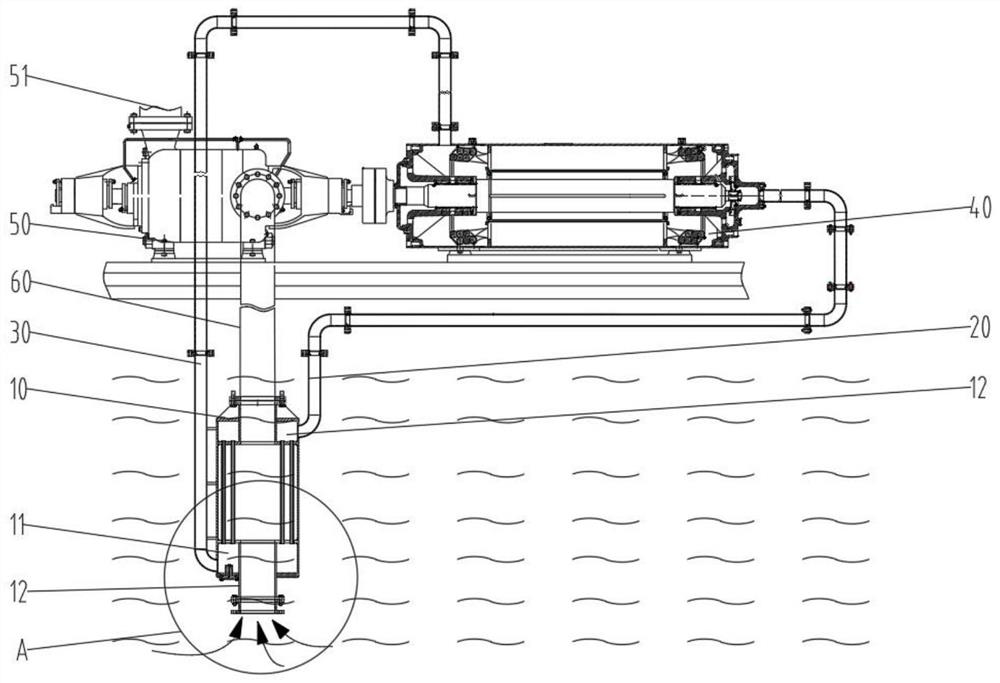

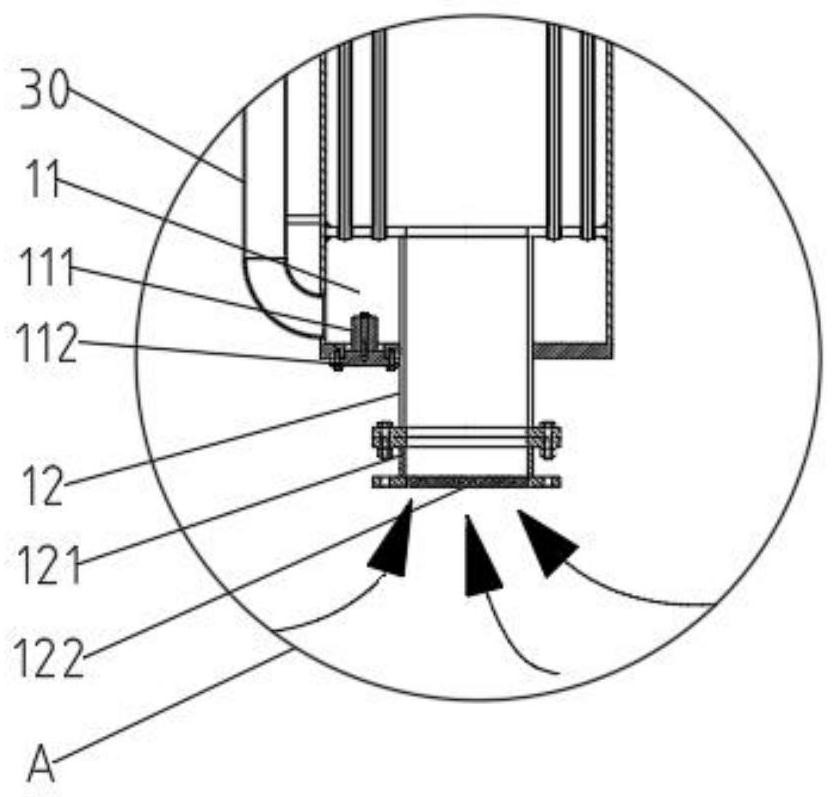

[0025] For ease of understanding, combined here Figure 1-2 , the concrete structure and working mode of the present invention are further described as follows:

[0026] The specific structure of the present invention is as Figure 1-2 As shown, it mainly includes a motor cavity 40, the motor is placed inside the motor cavity 40, the motor cavity 40 is provided with a cavity, and the cavity is located outside the motor rotor cavity. The cavity is filled with coolant, and when the rotor of the motor heats up, the heat is transferred to the coolant in the cavity for heat exchange, thereby cooling the motor.

[0027] It also includes a cooler 10, the cooler 10 is a hollow structure, and a cooling cavity 11 is provided inside it, and the cooling cavity 11 communicates with the motor cavity 40, and the cooling fluid after heat exchange flows into the cooling cavity 11 along the hot water pipe 30 for cooling .

[0028] The cooling chamber 11 surrounds the inner pipe 12 to increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com