A method for tailoring the low temperature test conditions of the whole aircraft in the laboratory

A low-temperature test and laboratory technology, applied in the direction of aircraft component testing, instruments, measuring devices, etc., can solve the problems of poor effectiveness and high cost of low-temperature tests, and achieve strong theory, good operability and versatility, and easy to promote and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

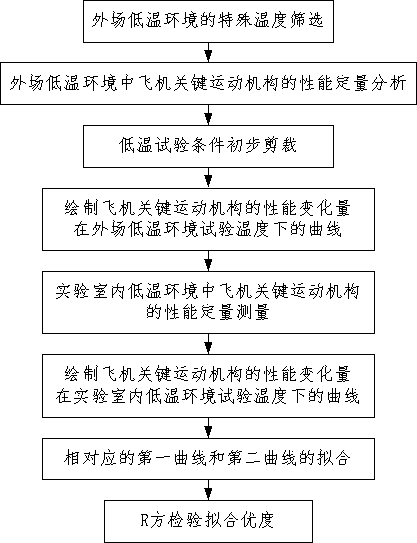

[0026] Such as figure 1 As shown, a method for tailoring the low temperature test conditions of an aircraft complete machine in a laboratory of the present invention comprises the following steps:

[0027] Step 1. Special temperature screening for the low-temperature environment in the field. The process is as follows:

[0028] Step 101, according to the formula , to determine the primary special temperature of the external low temperature environment , where i is the number of days and i=1, 2, ..., 365 or 366, j is the number of hours and j=1, 2, ..., 24, Represents the temperature of the j-th hour in the i-th day of the year, when i=1, is the temperature of the jth hour in the last day of the previous year, is the temperature of the jth hour in the penultimate day of the previous year, and △T is the temperature difference threshold;

[0029] Step 102, filtering out the primary special temperature The primary special temperature with a probability of less than 10%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com