Fast, stable and simple three-coordinate measuring machine needle head diameter reasoning method

A three-coordinate measuring machine and reasoning method technology, applied to measuring devices, instruments, etc., to achieve the effects of stable methods, easy promotion, and fast algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

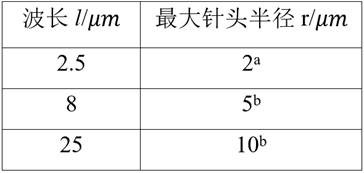

[0034] The following are specific examples of the present invention. With reference to the wavelength example provided by the national standard GB / T 6062-2009, the scheme of the present invention is used for further description. The needle diameter obtained by the present invention is the same as that provided by the national standard GB / T 6062-2009. Comparison of needle diameter values. However, the present invention is not limited to these Examples.

[0035] The national standard GB / T 6062-2009 provides an example of the wavelength corresponding to the maximum needle diameter for measuring surface roughness:

[0036]

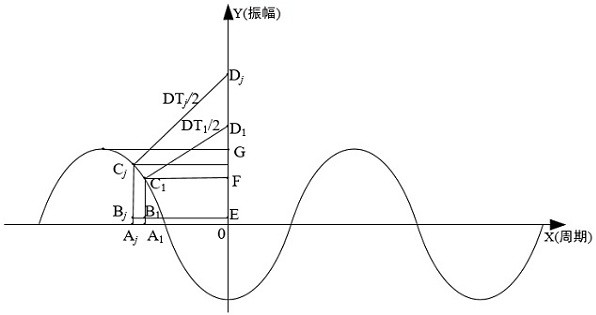

[0037] Step 1: Assuming that the waviness of the measured surface of the part is a sinusoidal waveform, the obtained wavelength is , corresponding to the amplitude h =0.003 mm .

[0038] After step 1, proceed to step 2.

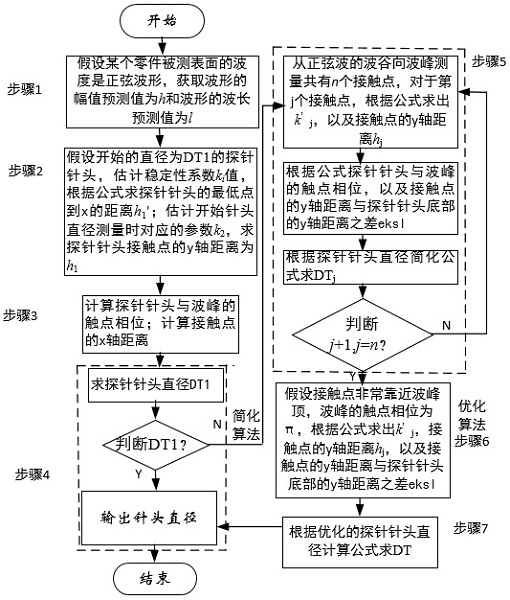

[0039] Step 2: Assume that the starting diameter is DT1 probe needles. Stability factor m=1 for probe needle diameter, k 1 = 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com