Full-process automatic tree planting method

A whole-process, sapling technology, applied in planting methods, botanical equipment and methods, climate change adaptation, etc., can solve the problems of low tree planting efficiency and low degree of automation, achieve flexible and diverse action modes, reduce workload, improve The effect of tree planting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

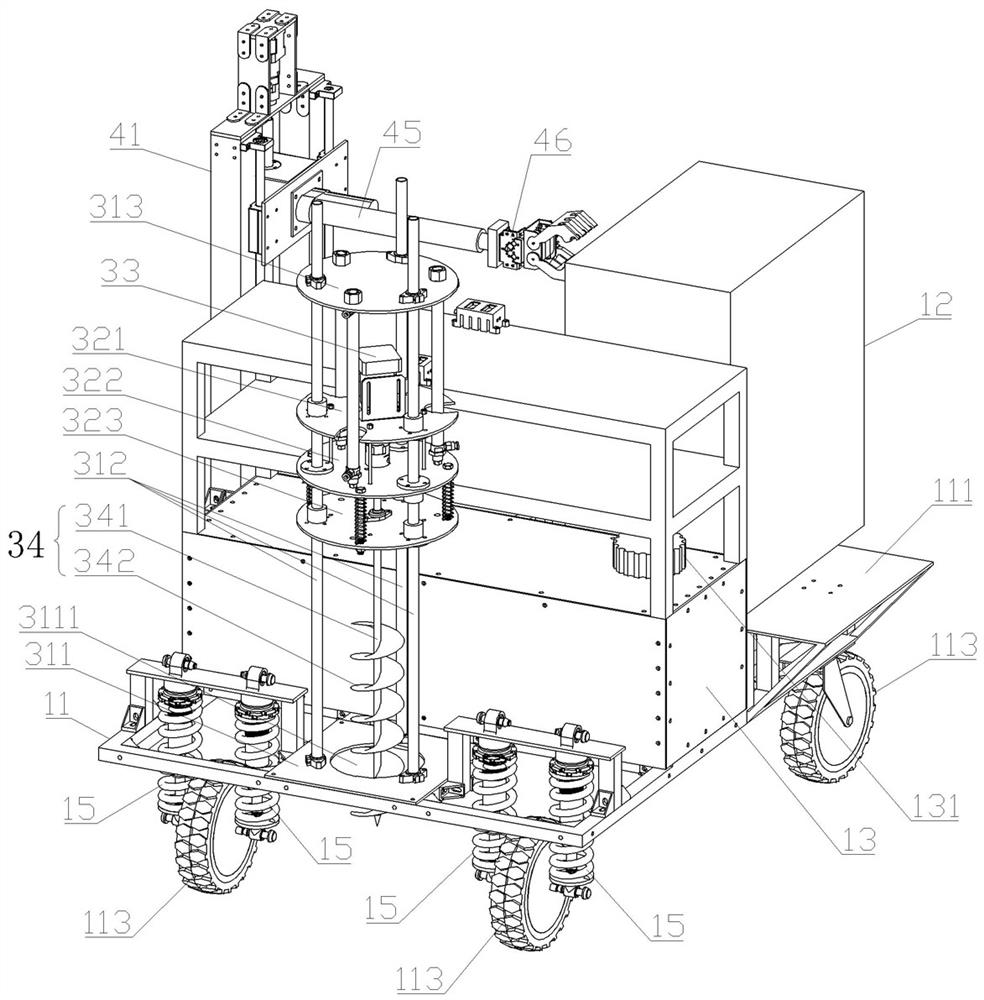

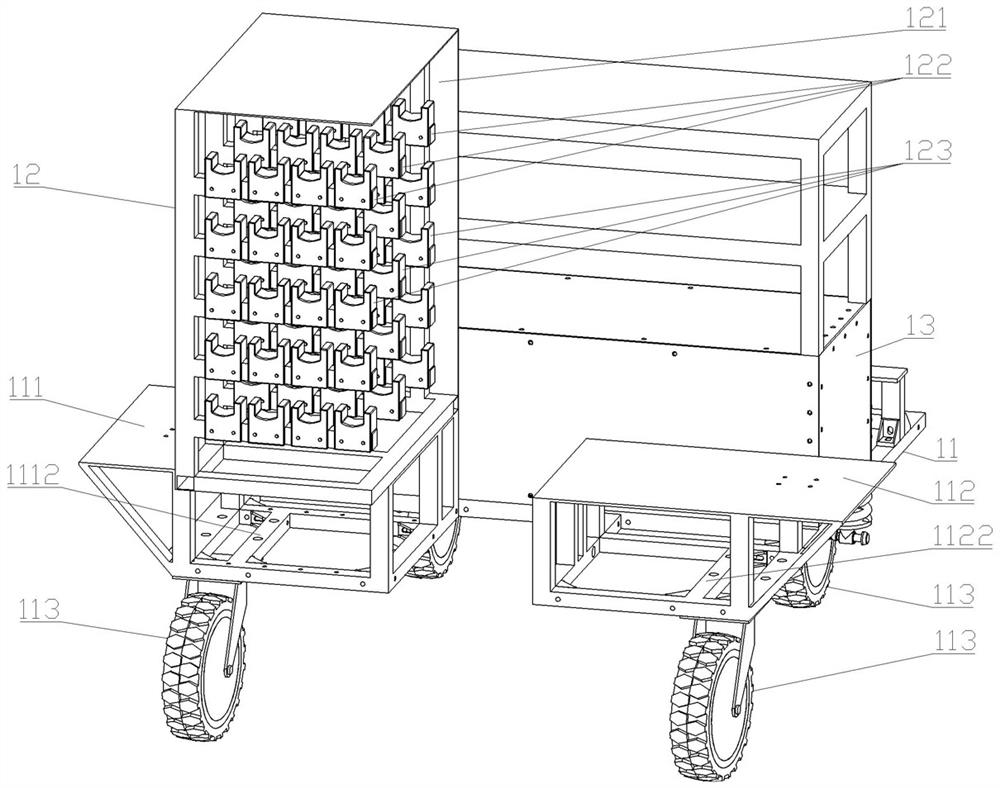

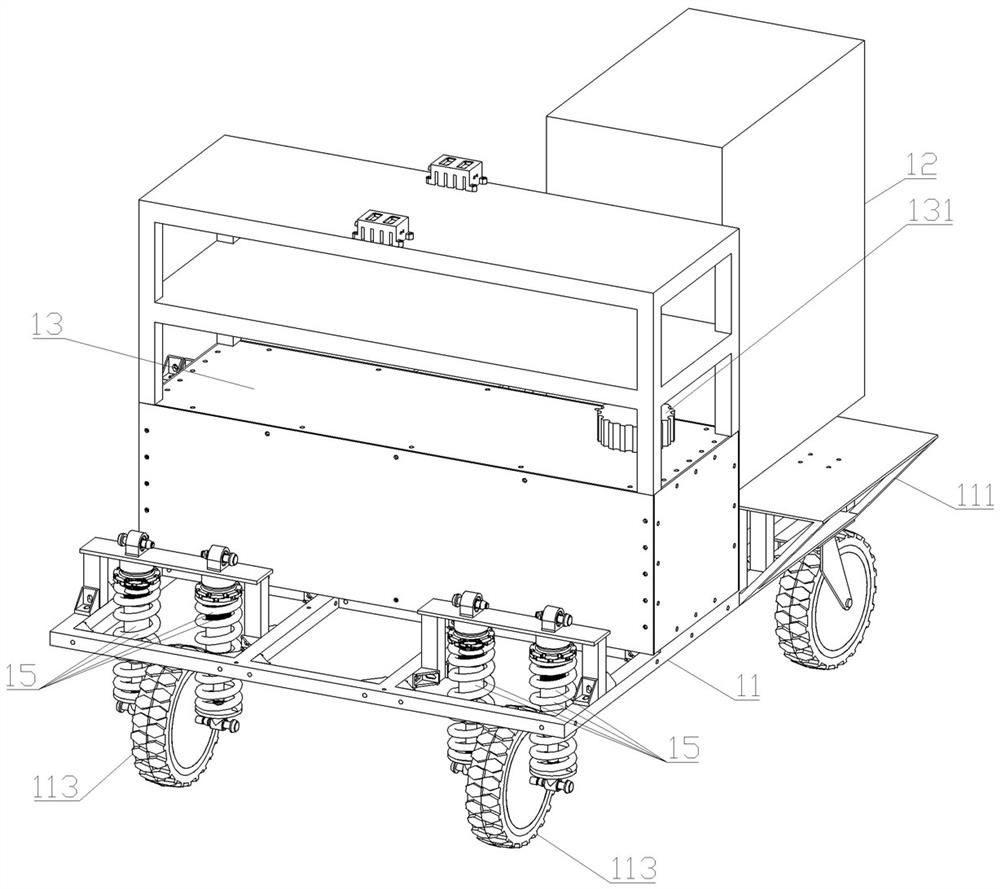

[0064] Such as Figure 1-6 As shown, the tree-planting robot includes a movable frame, a watering mechanism, a drilling mechanism, a grasping mechanism, a soil-building mechanism and a ramming mechanism.

[0065] The movable frame includes a base 11, a sapling placement box 12 and a water tank 13. The central area of the front end of the base 11 is provided with an installation section C for installing the drilling mechanism, and the two sides of the rear end of the base 11 are respectively provided with a frame A111 and a frame B112. A1112, the inner upper end of the frame B112 is provided with a top wall B, and the inner lower end of the frame B112 is provided with a supporting rod B1122. Just above the frame A111 is provided with an installation section A for installing the sapling placement box, and just above the frame B112 is provided with an installation section B for installing the gripping mechanism. In the operation section on the ground, a plurality of rollers 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com